Flat knitting machine fabric stretching apparatus

A pulling device and fabric technology, applied in the directions of knitting, weft knitting, textile and paper making, etc., can solve the problem that the fabric cannot be automatically guided and pulled, etc., and achieve convenient operation of fabric winding, reduction of manufacturing cost, and smooth fabric. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

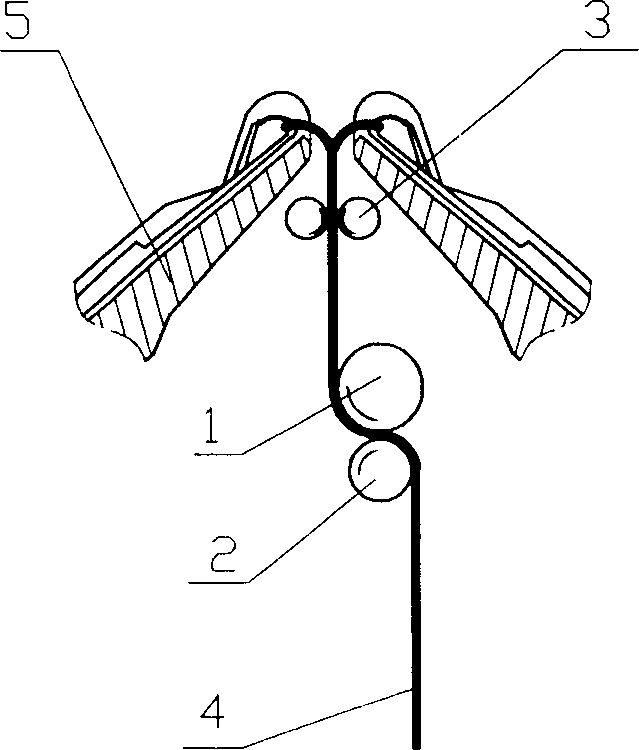

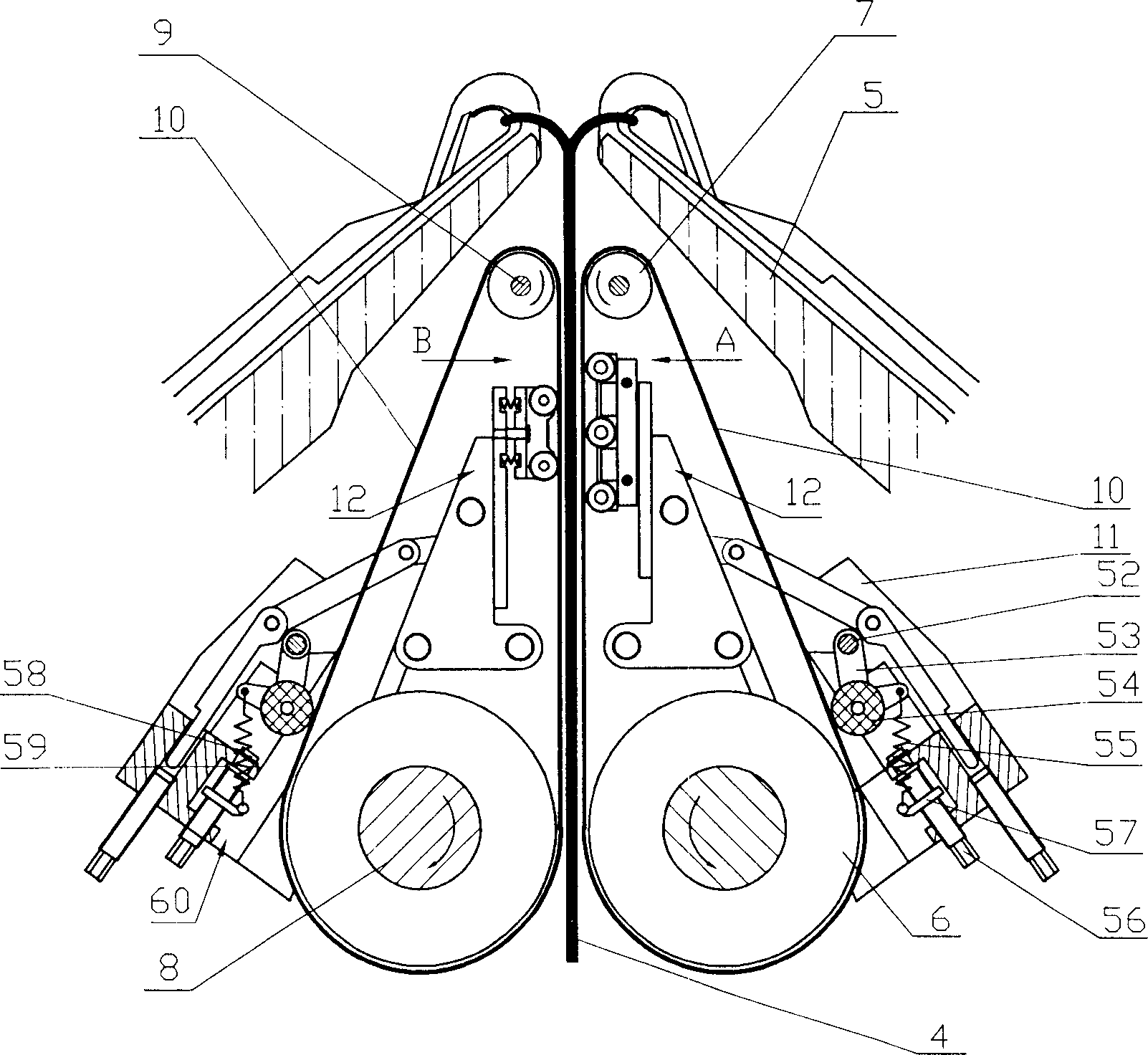

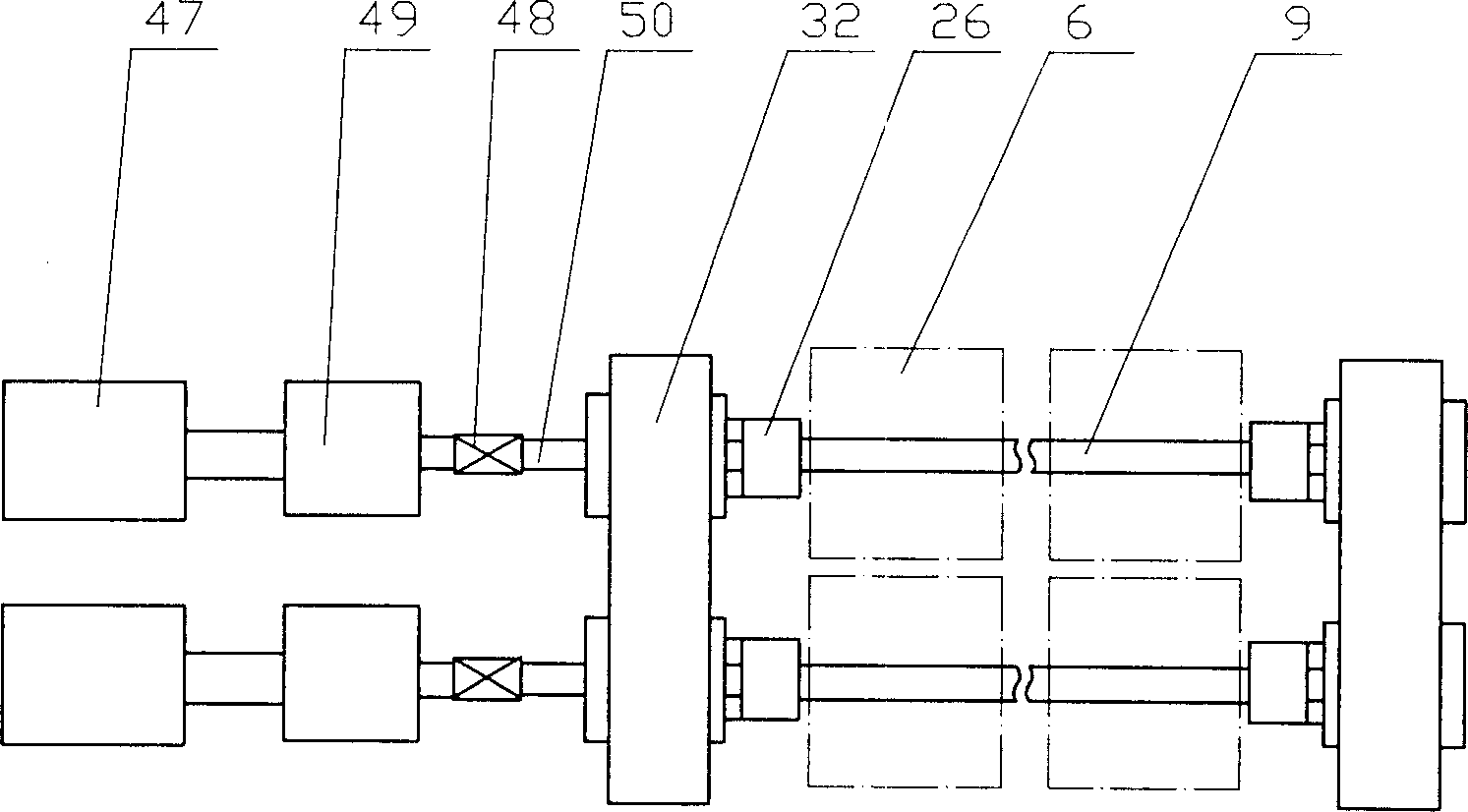

[0024] control figure 2 , the transmission mechanism on both sides of the conveyor belt composed of the large roller 6, the small roller 7, the large roller shaft 8, the small roller shaft 9, the conveyor belt 10 and the gap adjustment mechanism 12 is symmetrically placed on the lower side of the needle plate 5, the overall structure of the device of the present invention The triangular outline shape is very similar to the space on the lower side of the needle board, so the device of the present invention can be placed on the lower side of the needle board 5 very compactly, and the distance from the knitting needle to the device of the present invention is very small, only 20-30mm, and the fabric 4 The clamping length in the drive belt 10 can reach 200-250 mm, which is very beneficial to the flatness of the clamped and wound fabric 4 .

[0025] The la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com