Textile fabric drying device for textile production and processing

A technology for textile fabrics and drying devices, applied in the textile field, can solve the problems of easy wrinkling of fabrics, long drying time and low efficiency, etc., and achieves the effects of good use stability, convenient leveling and adjustment, and reasonable device structure layout.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

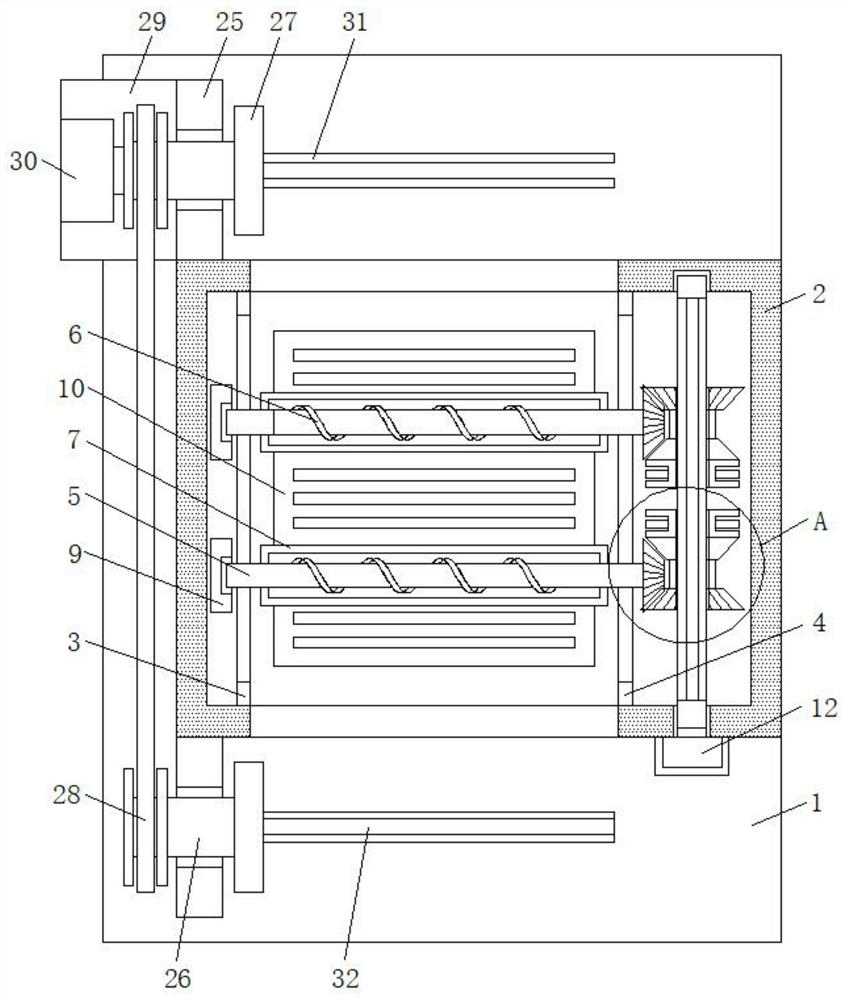

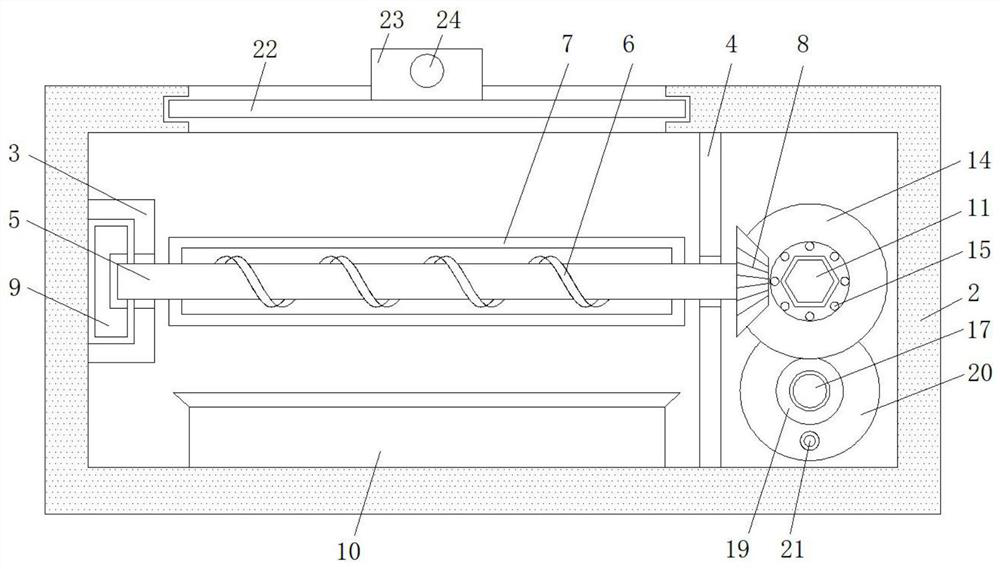

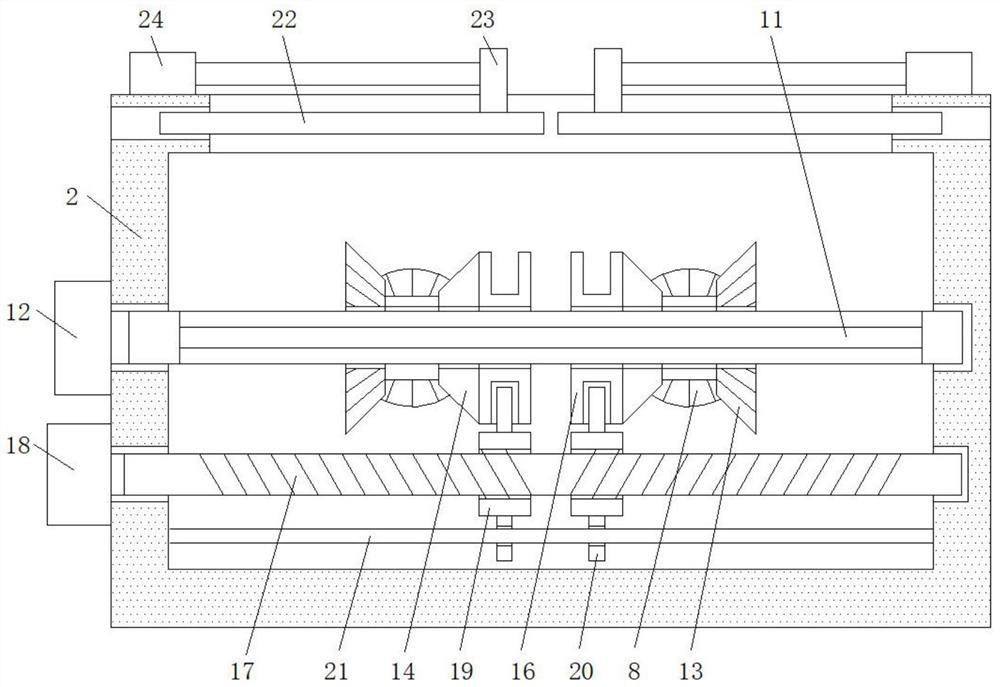

[0031] refer to Figure 1-4 , a textile fabric drying device for textile production and processing, comprising a flat plate 1, a drying box 2 is fixedly arranged on the top side of the flat plate 1, and a limit box 3 and a limiting box 3 are fixedly connected between the vertical side walls of the drying box 2 Support plate 4, and the inner side of limit box 3 slides and is provided with slide block 9, and the side wall body of limit box 3 and the board body of support plate 4 all offer rectangular through holes, and limit box 3 and support plate 4 A rotating shaft 5 is arranged horizontally between them, and the two ends of the rotating shaft 5 pass through two rectangular through holes respectively, and one end is rotationally connected with the slider 9, and the other end is fixedly connected with a bevel gear-8, the rotating shaft 5, the sliding block 9 and Bevel gear-8 is provided with two, two rotating shafts 5 are arranged in parallel, and the shaft body outside of rota...

Embodiment 2

[0037] Such as Figure 1-4 As shown, the present embodiment is basically the same as Embodiment 1, and the more optimized part is that the top side of the flat plate 1 is provided with a fabric conveying and winding assembly, and the fabric conveying and winding assembly includes a riser 25, and the bottom side of the riser 25 is connected to the plate. 1 is fixedly connected, and two vertical plates 25 are arranged symmetrically and are respectively located on both sides of the drying box 2, and a circular shaft 26 is installed in the plate body of the vertical plate 25, and a pulley 28 is installed between one end of the two circular shafts 26 , the other ends are fixedly connected with mounting plates 27, and one side of the two mounting plates 27 is fixedly connected with a winding rod 31 and a mounting rod 32 respectively, and two winding rods 31 are arranged in parallel, one side of the vertical plate 25 Fixedly connected with horizontal plate 29, and motor three 30 are ...

Embodiment 3

[0040] Such as Figure 1-4 As shown, this embodiment is basically the same as Embodiment 1, and the more optimized place is that two door assemblies are arranged symmetrically on the top of the drying box 2, and the door assembly includes a top plate 22, and the top plate 22 is slidably arranged on the drying box 2. In the top wall, and the top side of top plate 22 is fixedly connected with push plate 23, the top wall of drying box 2 is equipped with electric telescopic rod 24, and the output rod of electric telescopic rod 24 is connected with push plate 23 transmissions.

[0041] In this embodiment, the electric telescopic rod 24 is opened, and the output rod of the electric telescopic rod 24 shrinks or extends horizontally, which can drive the push plate 23 to move horizontally, and then drive the top plate 22 to move horizontally in the top wall of the drying box 2. Sliding, so that the top side of the drying box 2 is opened or closed, which is convenient for feeding and so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com