Packaging film winding device with adjustable winding direction

A technology of winding direction and winding device, which is applied in the direction of object rotation and wrapping, which can solve the problems of inconvenient adjustment of winding direction and inconvenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

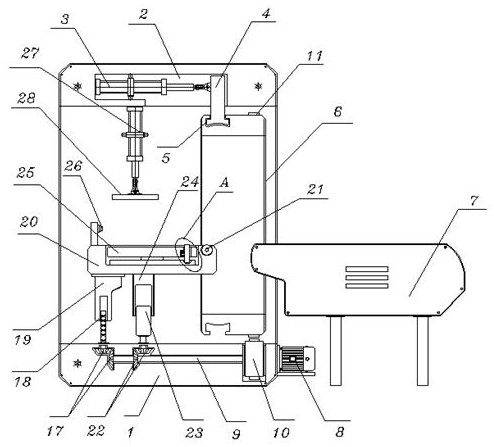

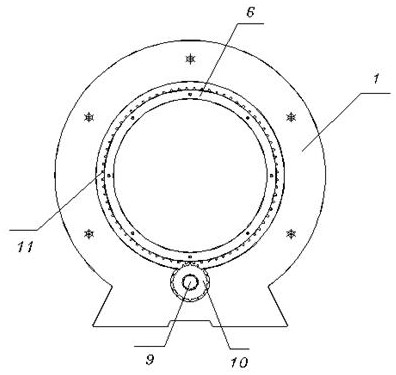

[0034] see Figure 1-7 Among them, including the body 1, an adjustment groove 2 is provided on the inner wall of the top of the body 1, and an adjustment rod 4 is connected to the adjustment groove 2 through a hydraulic rod 3, the bottom end of the adjustment rod 4 is located in the movable groove 5, and the movable groove 5 is opened On the outside of the winding ring 6, and the winding ring 6 is located in the body 1, and the side of the body 1 is equipped with a delivery seat 7; it also includes: a motor 8, the motor 8 is bolted to the bottom edge of the body 1, and the motor 8 The output end is connected with a guide post 9, and the guide post 9 is embedded and movably installed inside the bottom of the body 1. The front end of the guide post 9 is covered with a gear 10, and one end of the gear 10 protrudes from the inside of the body 1 and is arranged on the winding ring. 6, and the tooth block 11 is fixed at an equal angle at the corresponding position on the outside of ...

Embodiment 2

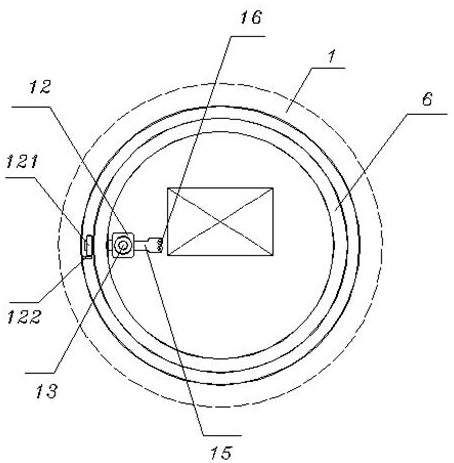

[0036] see figure 1 with Figure 3-4 Among them, the first bevel gear transmission assembly 17, the first bevel gear transmission assembly 17 is embedded in the bottom of the body 1, and one side of the first bevel gear transmission assembly 17 is provided with a second bevel gear transmission assembly 22, and the second bevel gear transmission assembly 22 Both the second bevel gear transmission assembly 22 and the first bevel gear transmission assembly 17 are sleeved on the guide post 9, the top of the first bevel gear transmission assembly 17 is connected with a reciprocating screw rod 18, and the reciprocating screw rod 18 is sleeved with a support rod 19, and the top of the support rod 19 is fixed with a winding table 20, and the top edge of the winding table 20 is embedded with a conveying roller 21, and the top of the second bevel gear transmission assembly 22 is connected with a movable bar 23, and the movable The top of the bar 23 is provided with a movable sleeve 24,...

Embodiment 3

[0038] see figure 1 with Figure 8-9 Among them, the edge of the coiling plate 25 is connected with a fixed rod 252 through the second spring 251, and the bottom of the fixed rod 252 is provided with a guide ring 253, and the guide ring 253 is fixed in the depression at the top of the coiling table 20, and the guide ring 253 The distribution position corresponds to the distribution position of the fixed rod 252, and the guide ring 253 is provided with a downward arc-shaped recessed area; when the coiled plate 25 rotates, it drives the fixed rod 252 to rotate, and cooperates with the restriction of the guide ring 253, so that the fixed The rod 252 can be ejected and fix the heat pressing and angle switching position of the packaging film, so as to avoid the packaging film falling off under tension during winding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com