Method for lifting Fischer-Tropsch reactor by 6400t hydraulic combined crane

A Fischer-Tropsch reactor, crane technology, used in cranes, transportation and packaging, load hoisting components, etc., can solve problems such as difficult hoisting tasks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

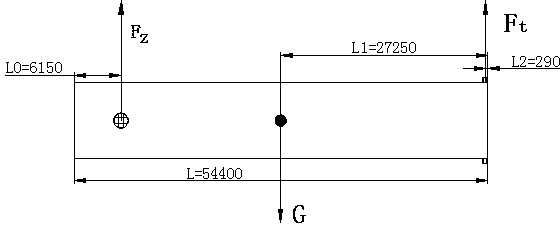

[0036] Hoisting force calculation:

[0037] F Z = k 1 k 2 G ( L 1 - L 2 ) L - L 0 - L 2

[0038] f t =k 1 k 2 G-F Z

[0039] G=G1 +G 2 +G 3

[0040] but:

[0041] G=2151+57.66+51.4=2260t

[0042] F Z = 1.1 × 1.1 × 2260 × ( 27250 - 290 ) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com