Yarn nozzle lifting device in flat knitting machine

A lifting device and yarn feeder technology, used in textiles and papermaking, weft knitting, knitting, etc., can solve the problems of easy failure, high work coordination requirements, and high overall component cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

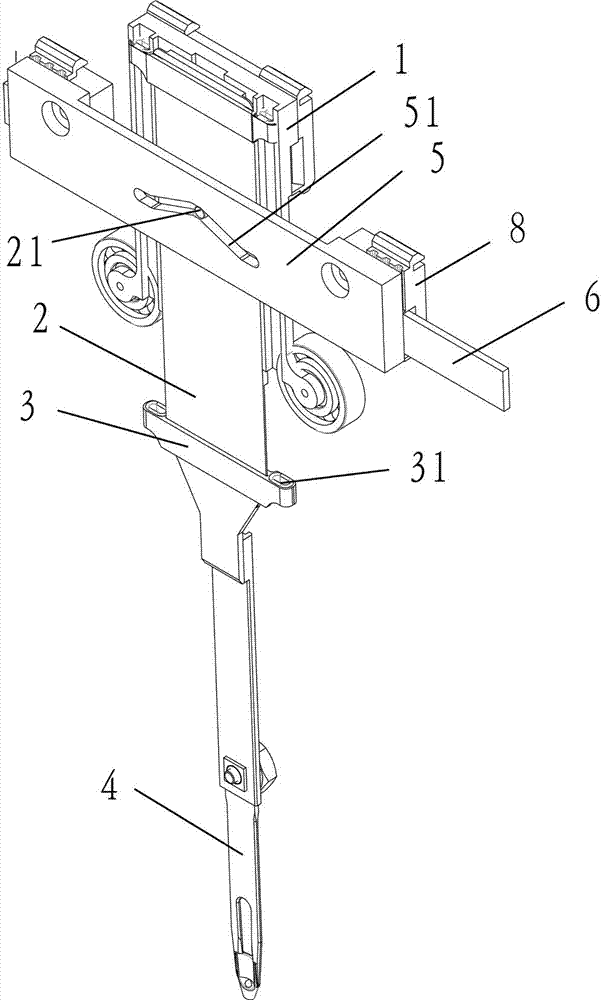

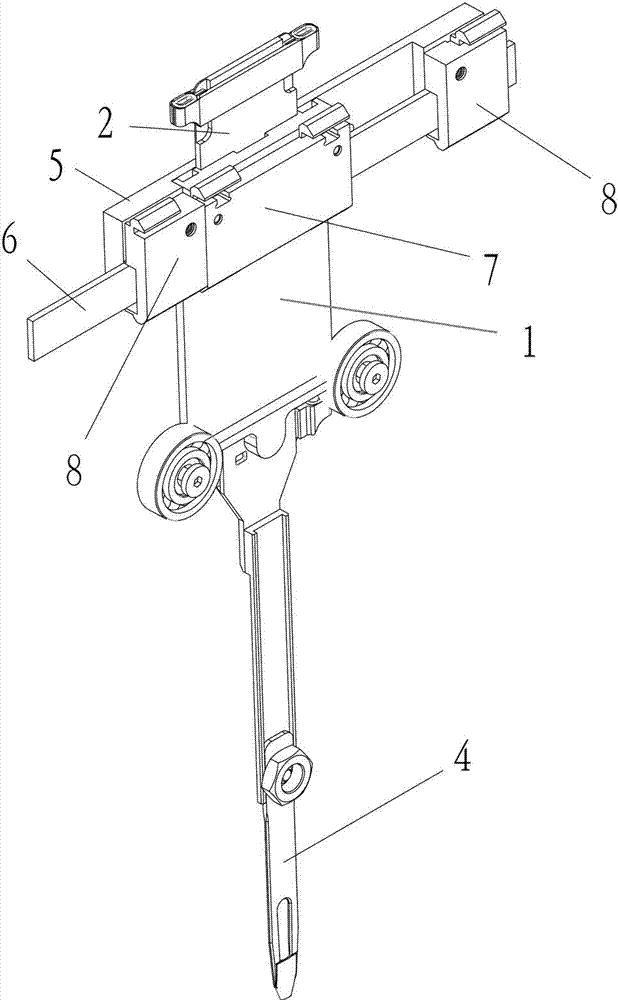

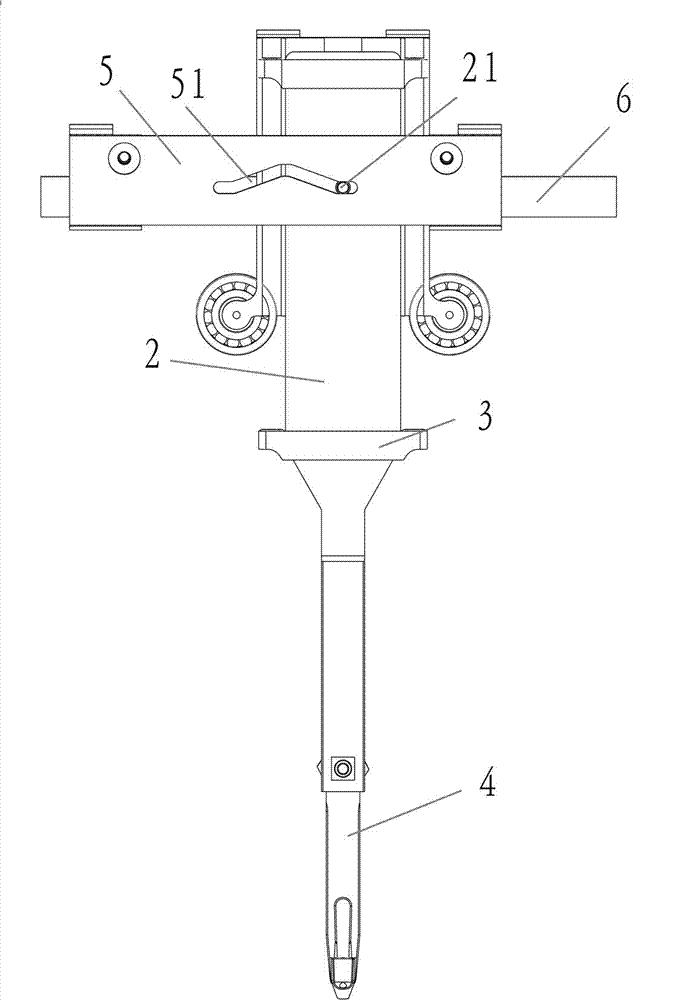

[0011] See attached picture. This embodiment includes Us seat 1, Us handle 2, porcelain eye seat 3, yarn feeder 4, timing belt cover 5 and timing belt 6; there is a rectangular slideway in the middle of the Us seat 1, Us handle 2 The upper end is placed on the rectangular slideway in the middle of the Us seat 1, the yarn feeder 4 is fixed on the lower end of the Us handle 2, the porcelain eye seat 3 is fixed on the Us handle 2, and the two ends of the porcelain eye seat 3 have porcelain eyes 31 ; There is a drive pin 21 on the url handle 2, a limit block 11 is fixed behind the urn seat 1, and there is a movable channel between the url seat 1 and the limit block 7; the timing belt 6 is placed on the urn In the movable channel between the seat 1 and the limit block 7; the synchronous belt cover plate 5 is located above the handle 2, and the two ends of the synchronous belt cover plate 5 are fixed on the synchronous belt 6 through the fixed block 8; the synchronous belt There is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com