Zinc-nickel secondary sealed cylindrical alkaline battery adopting nickel-plated shell as negative electrode and manufacturing method thereof

A secondary sealing, alkaline battery technology, applied in the manufacture of alkaline batteries, alkaline batteries, nickel storage batteries, etc., can solve the problems of affecting rate discharge performance, limiting battery capacity, small electrical connection area, etc., to improve rate discharge Effects of performance, extended battery life, and increased contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below using the accompanying drawings and examples.

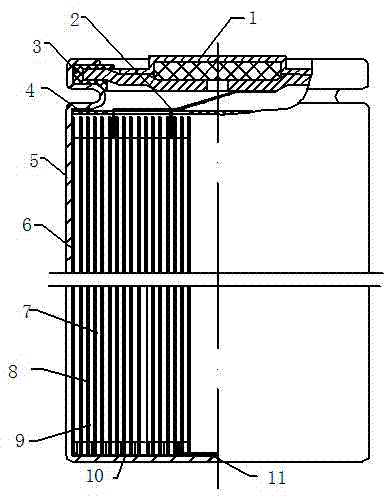

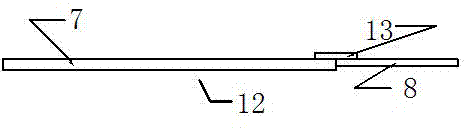

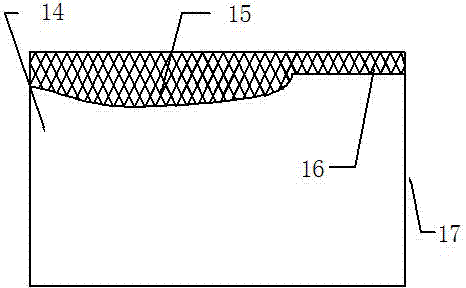

[0034] refer to figure 1 , figure 2 The zinc-nickel secondary sealed cylindrical alkaline battery with the nickel-plated shell of the present invention as the negative electrode includes a nickel-plated shell 5, and the upper end of the nickel-plated shell 5 is insulated and sealed fixedly connected with the nickel-plated cap 1 through a sealing ring 3. In the nickel-plated shell 5, a pole group wound by a negative electrode piece 9 with a negative tab, a diaphragm, a copper foil paste 12, and a positive piece 6 with a positive tab is arranged, and a negative pole piece 9 with a negative tab is connected with a positive tab with a positive tab. Between the positive plates 6 is a diaphragm 7, the diaphragm 7 is a composite film, and its tail is pasted with copper foil 8 or tinned copper foil, the outer ring of the pole group is copper foil 8, and one side of the copper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com