Patents

Literature

37results about How to "Flat and reliable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Culm sheath pretreatment system composed of airing shelf, burr removal device and spreading device

InactiveCN105835149AEffective flatteningReliable supportWood treatment detailsCane mechanical workingEngineeringHot press

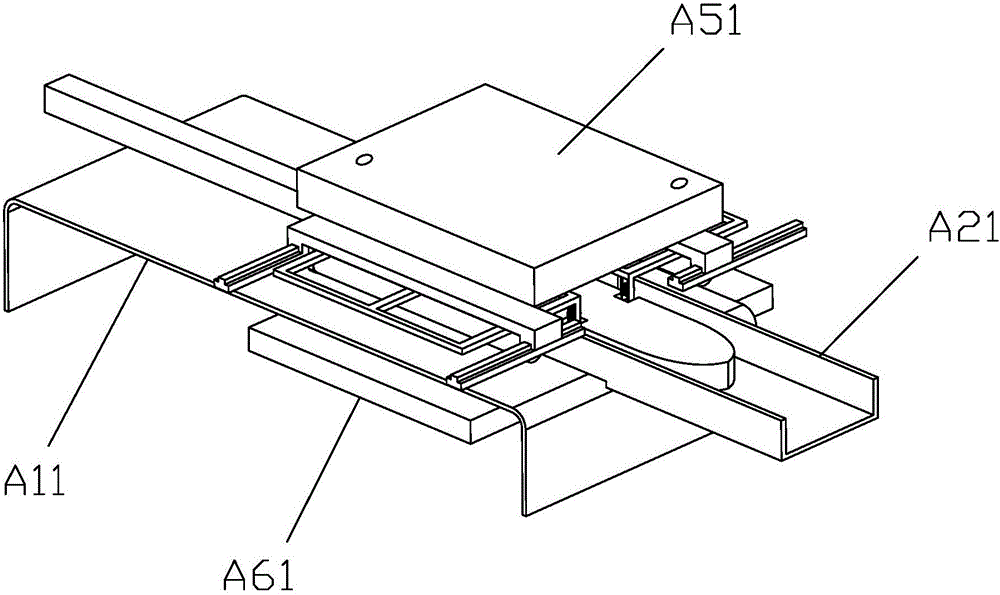

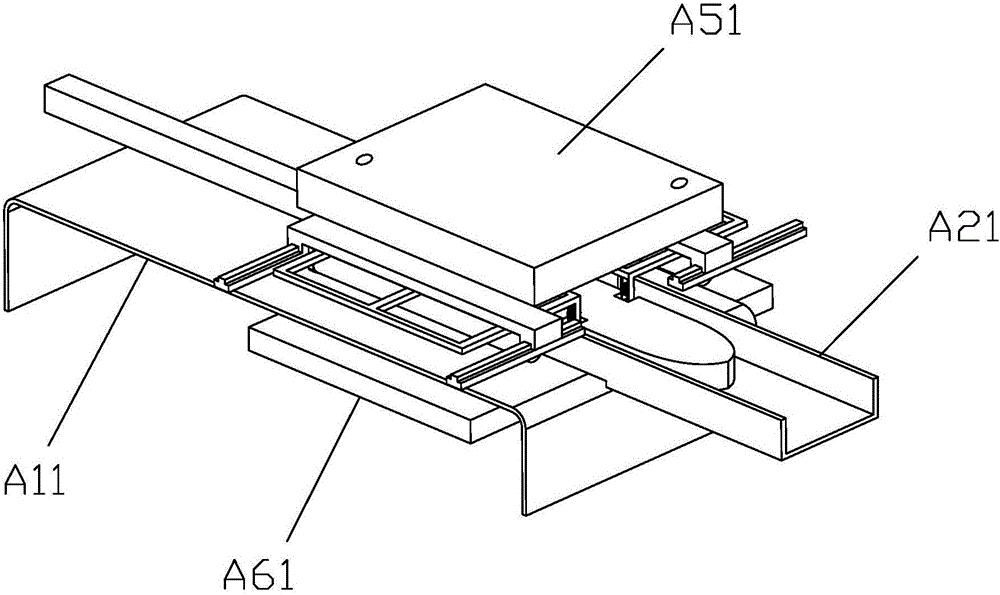

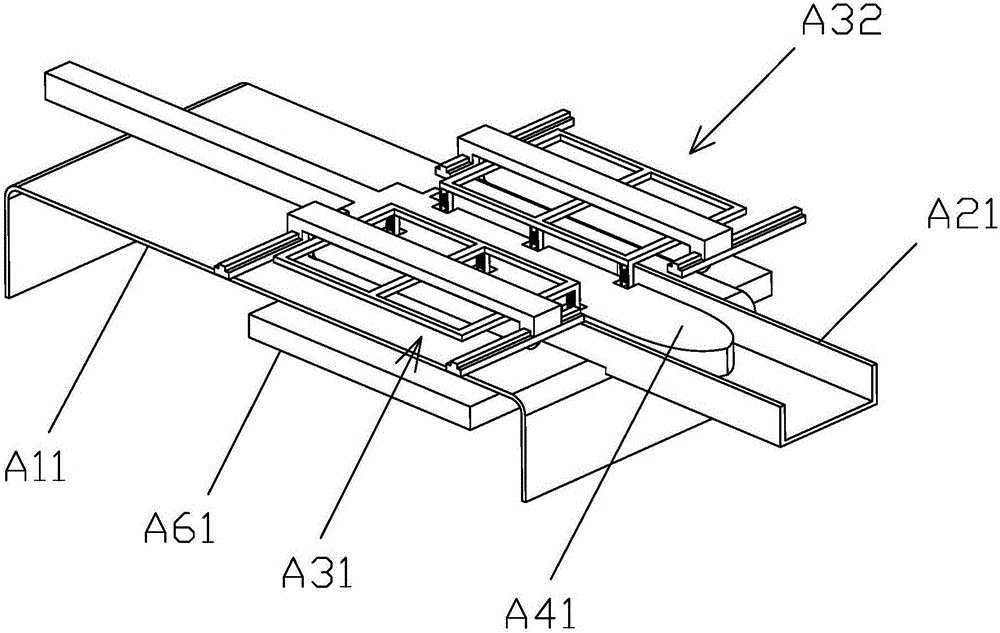

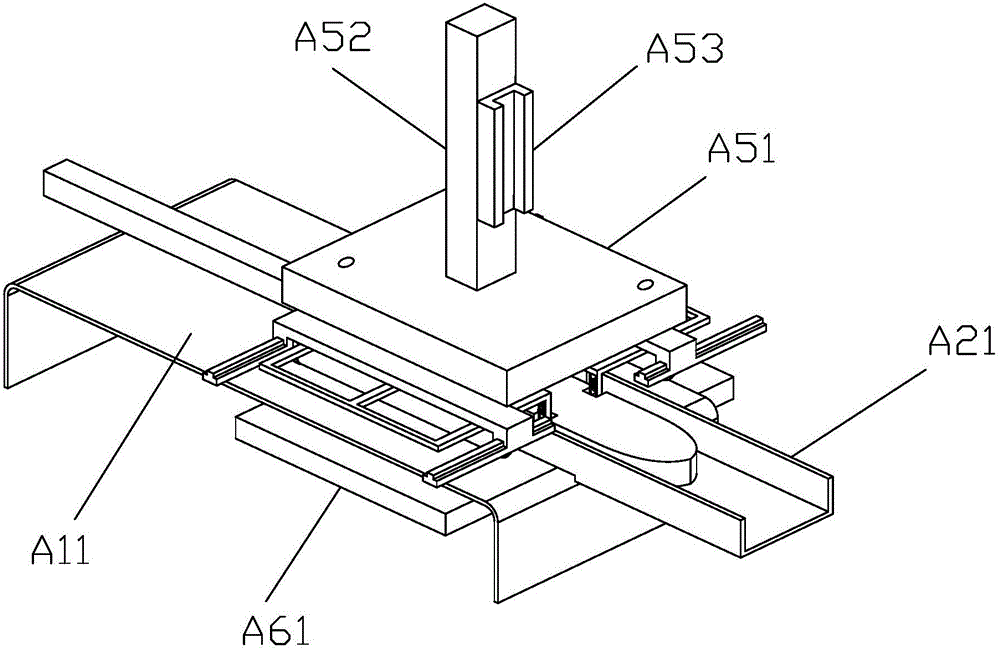

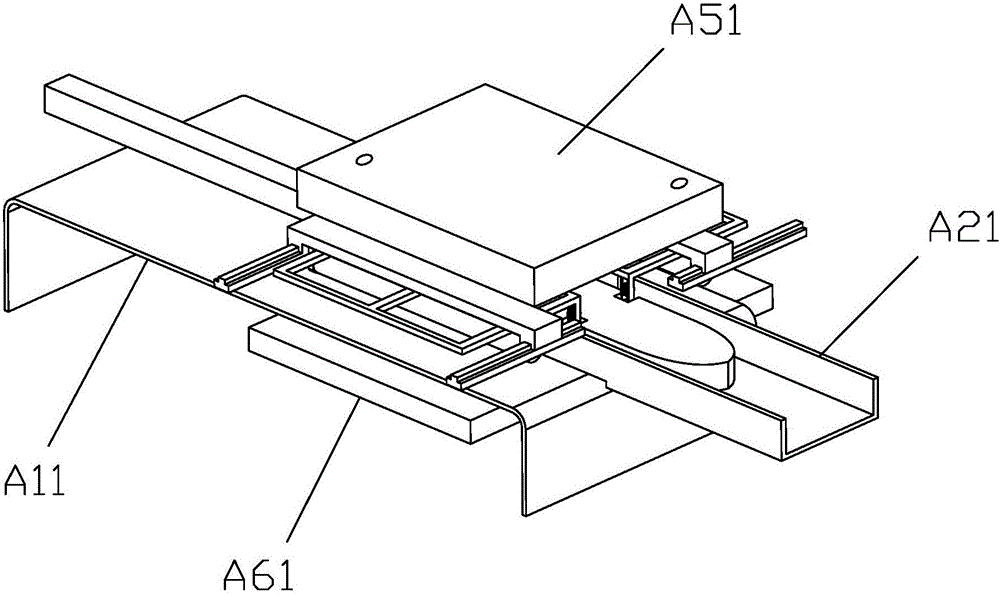

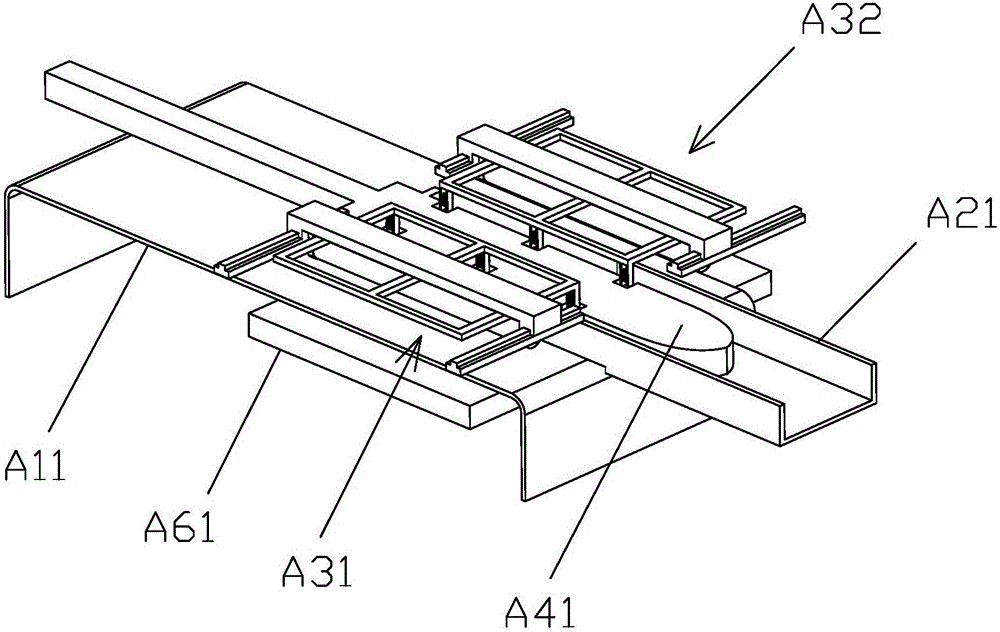

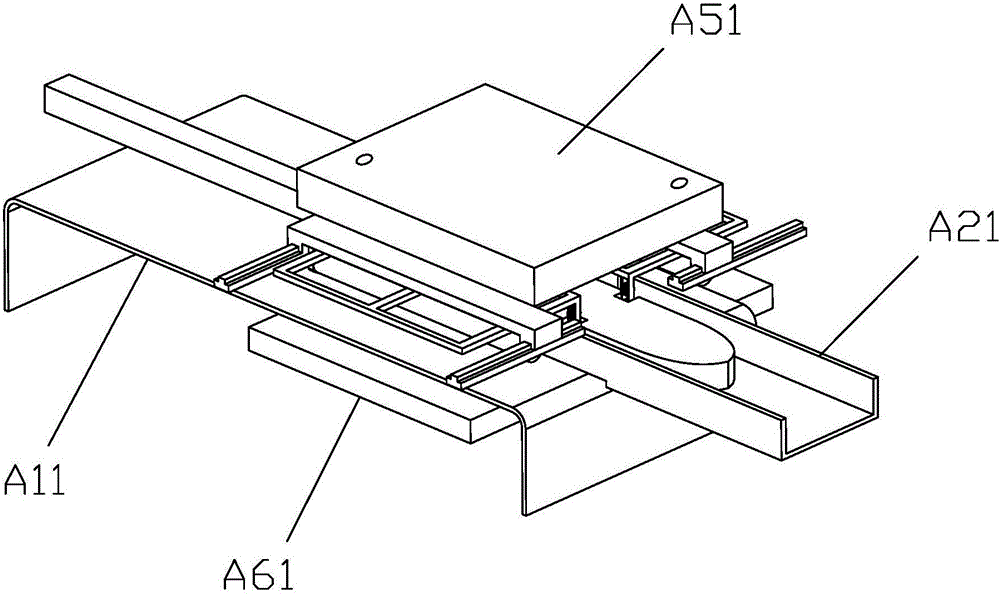

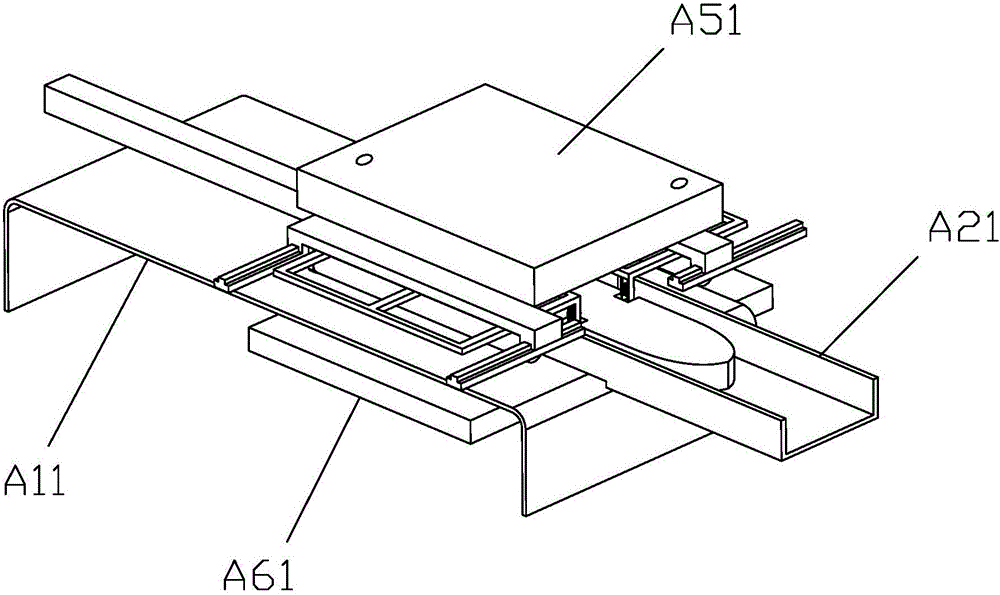

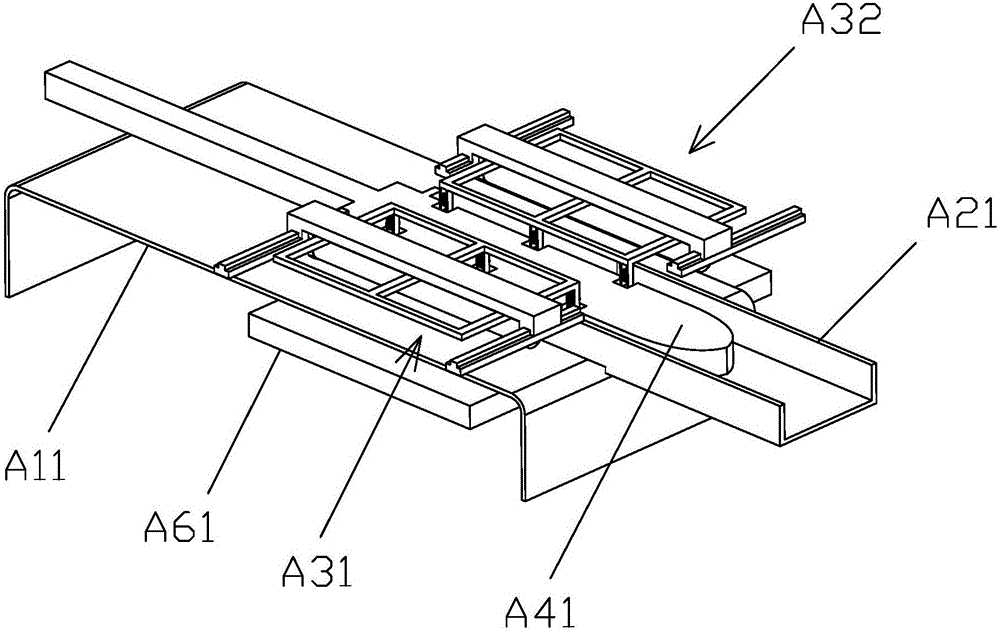

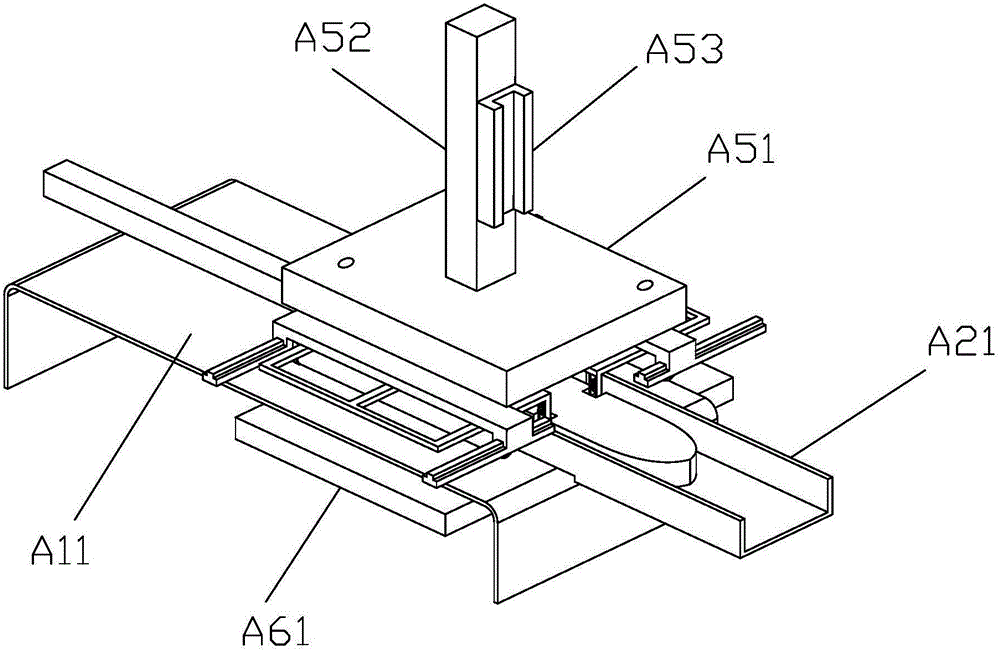

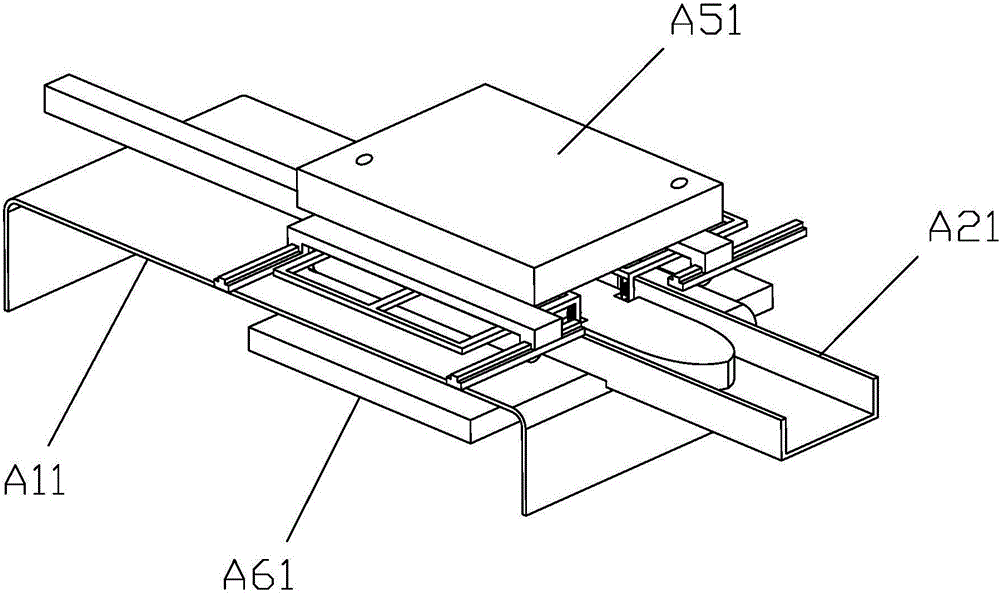

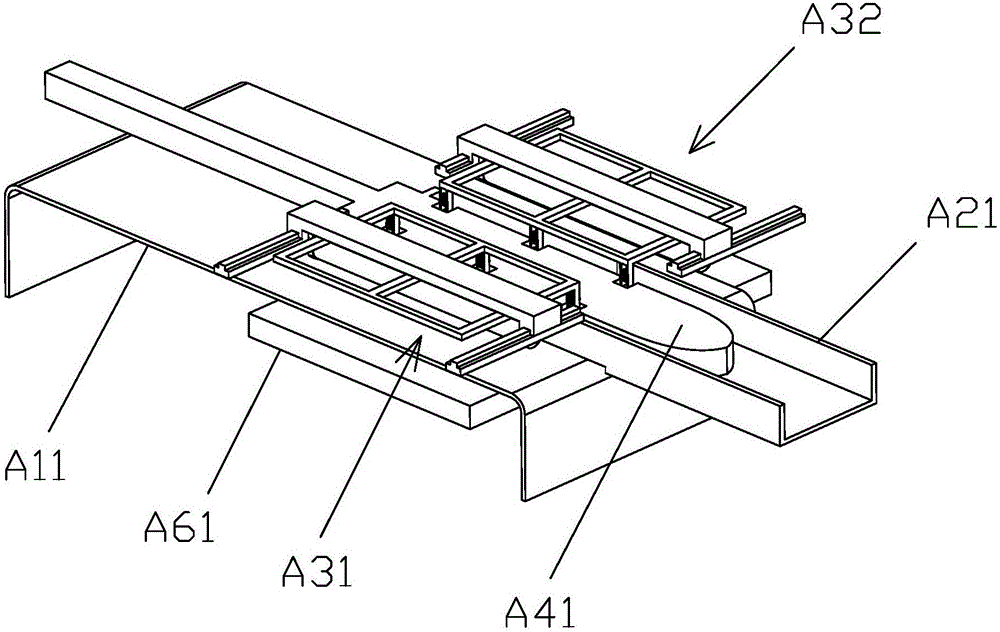

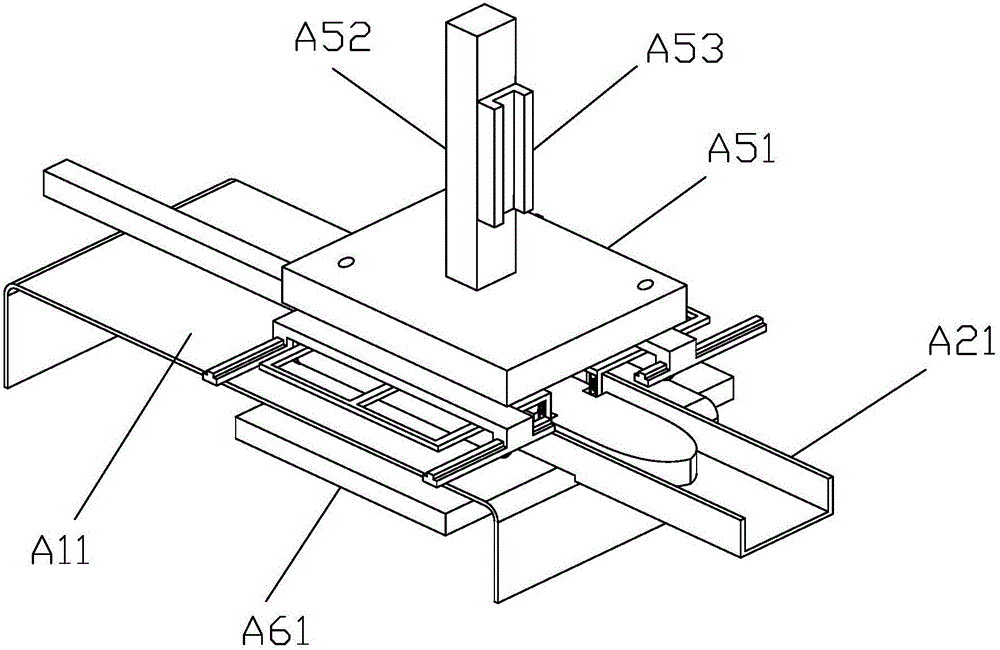

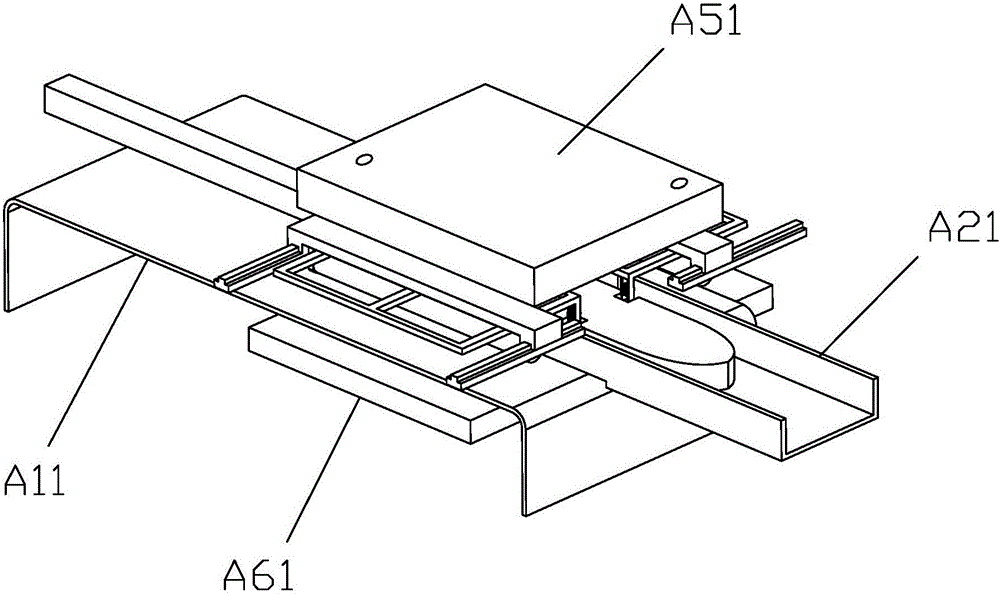

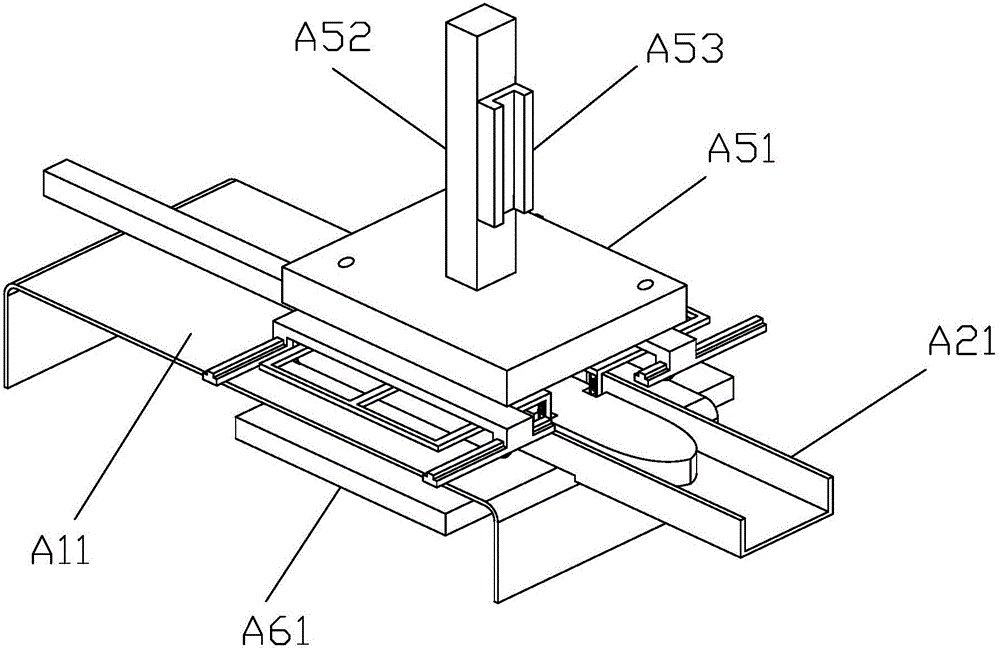

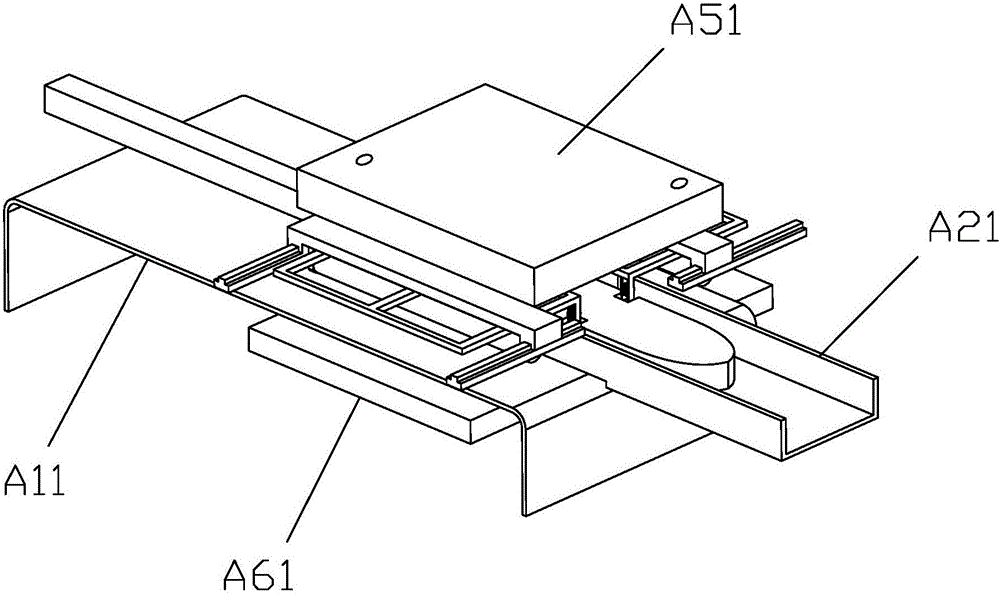

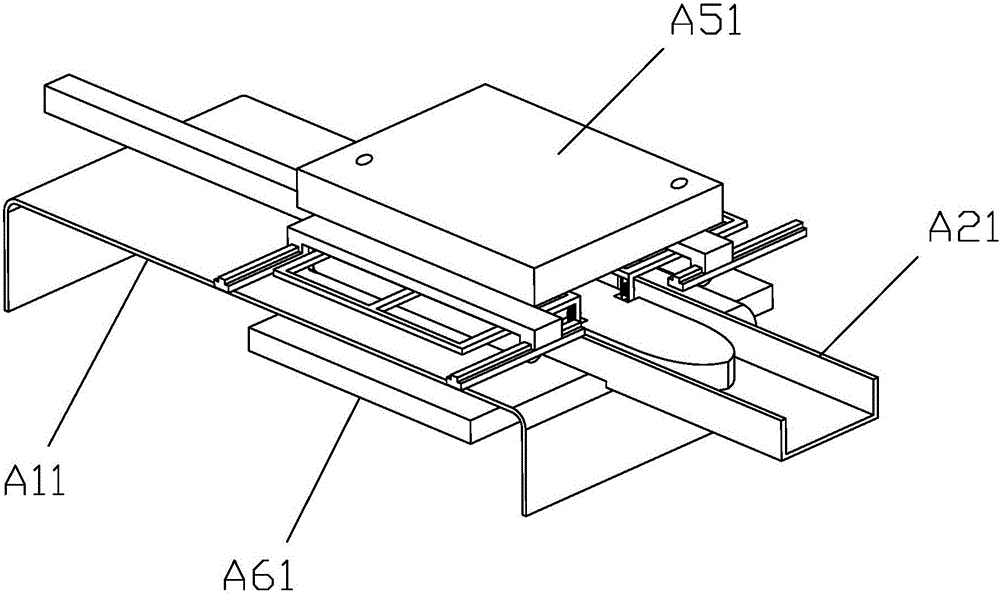

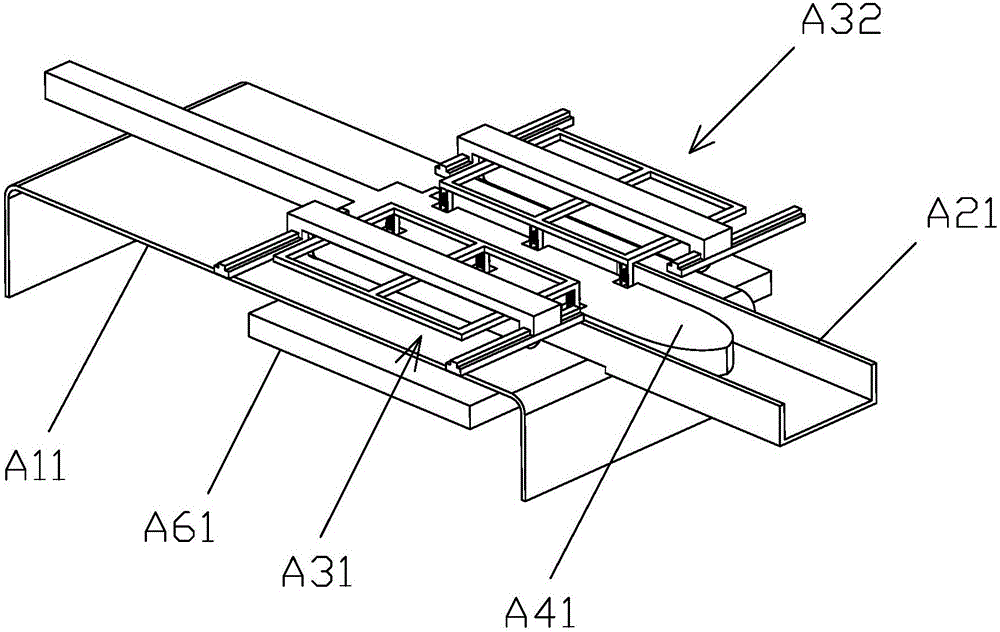

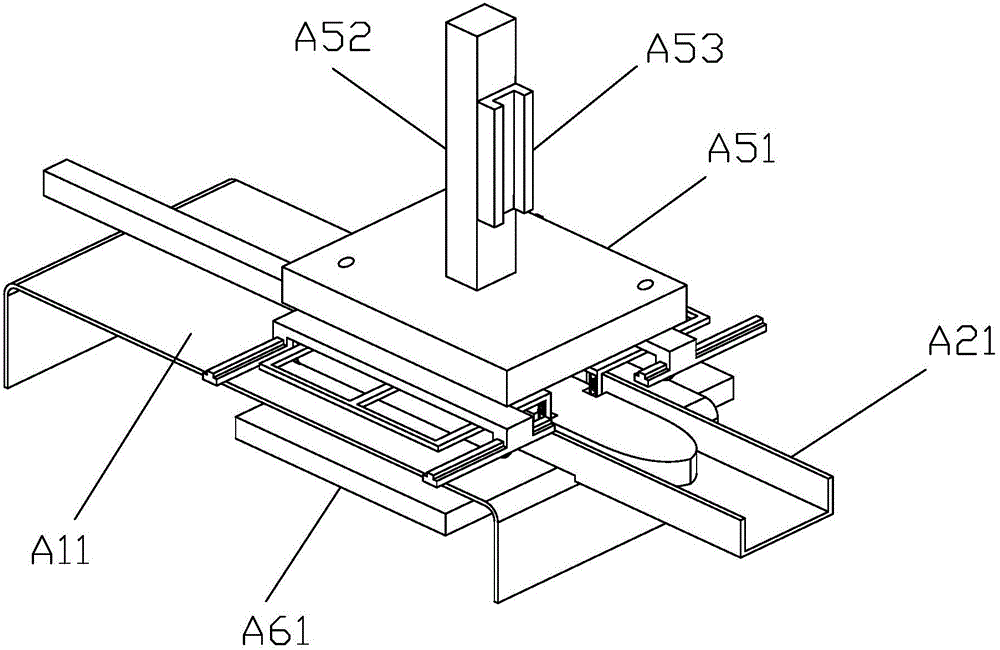

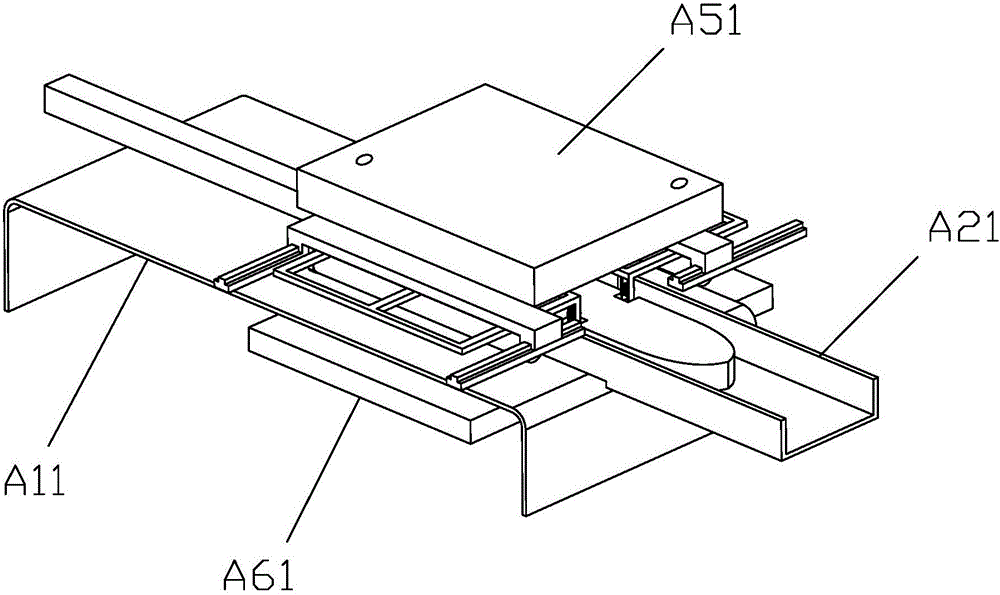

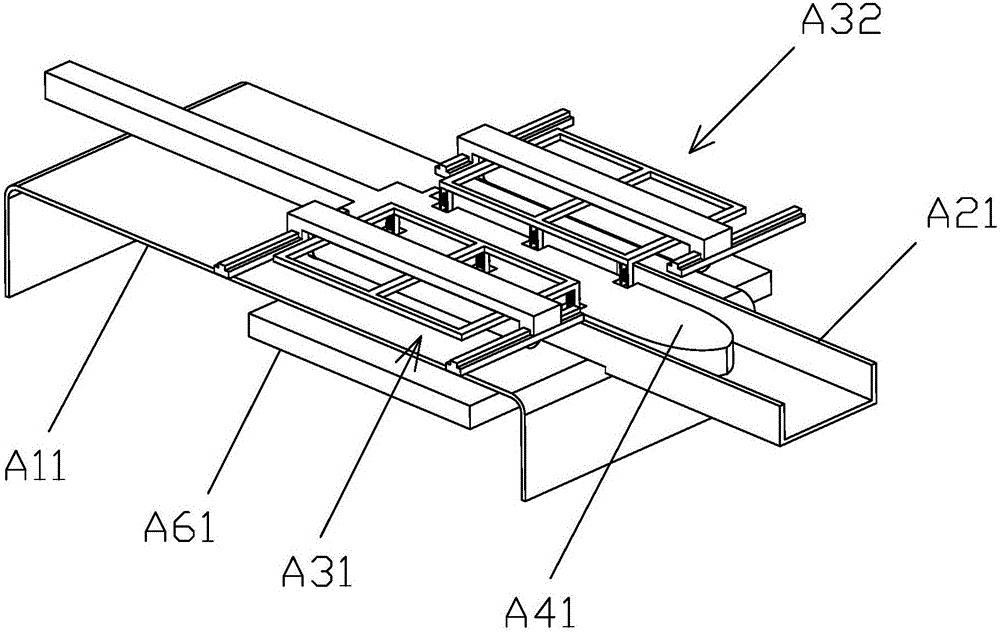

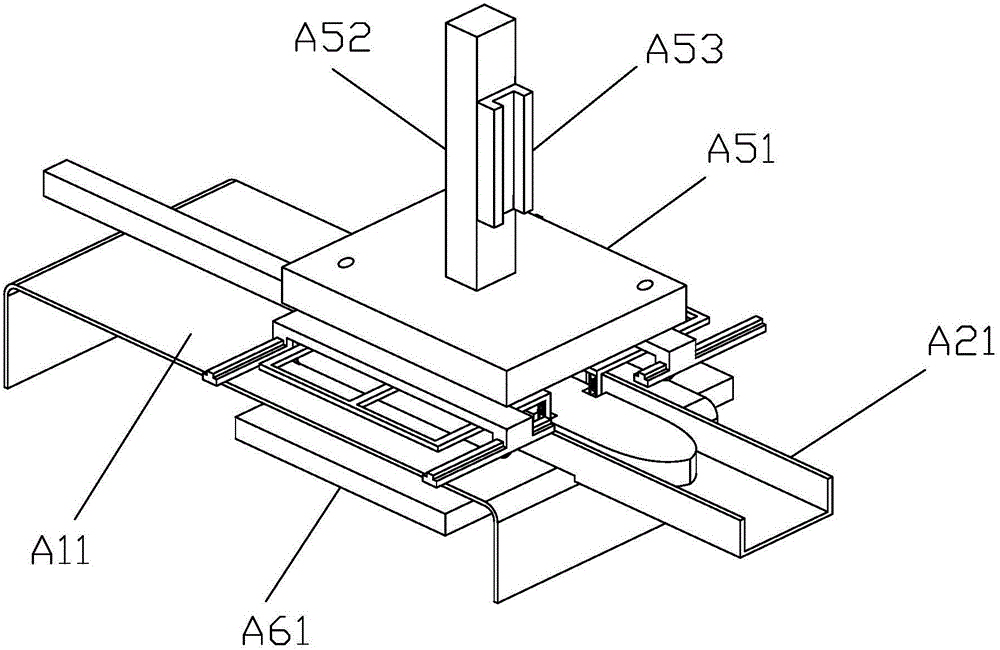

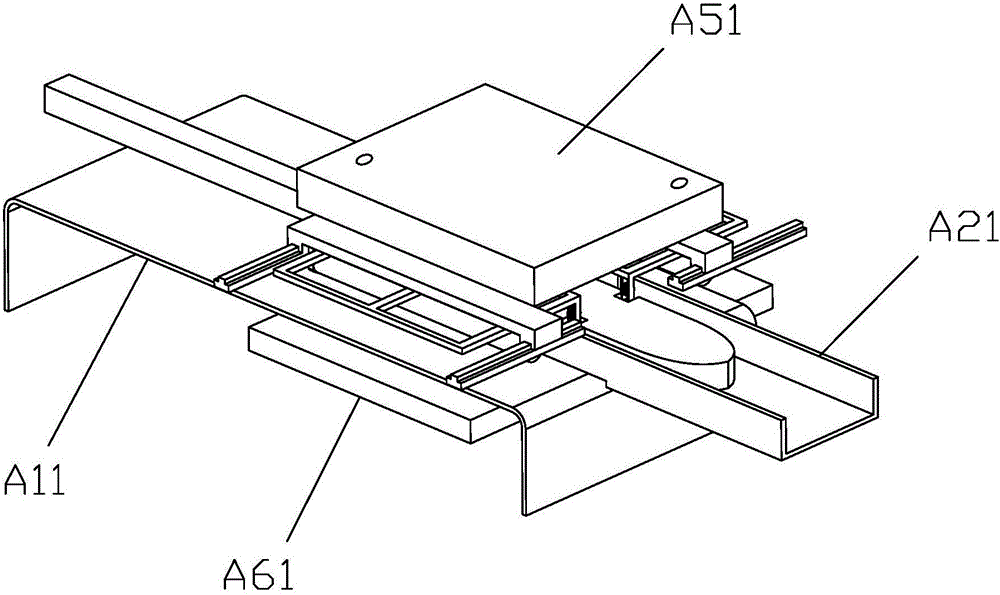

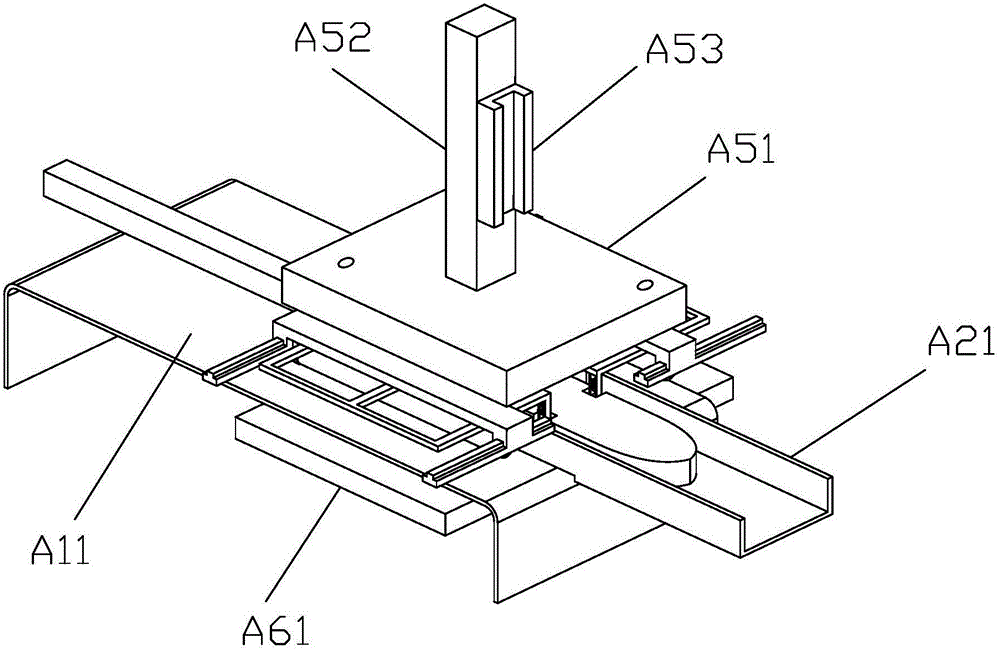

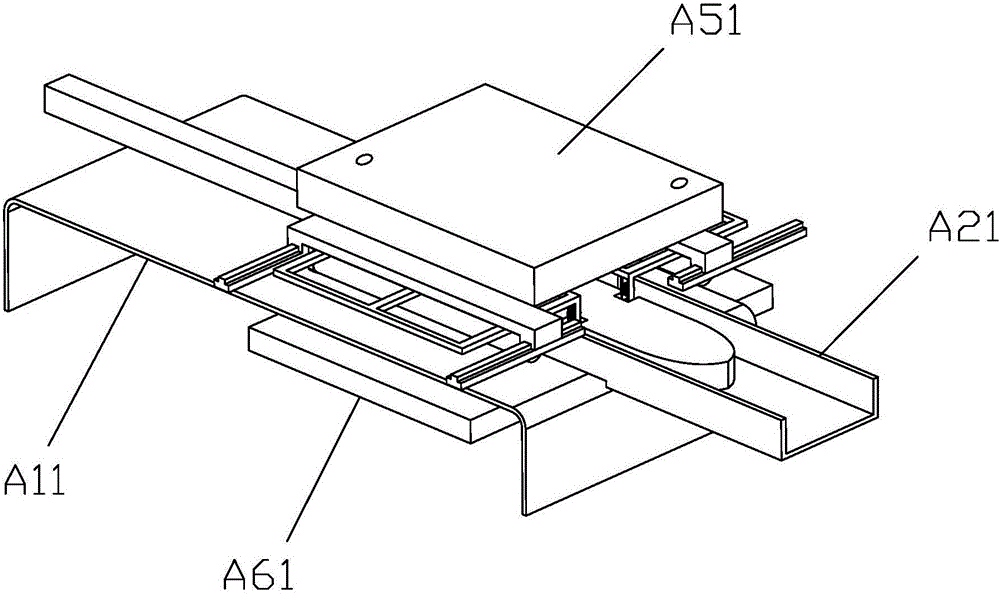

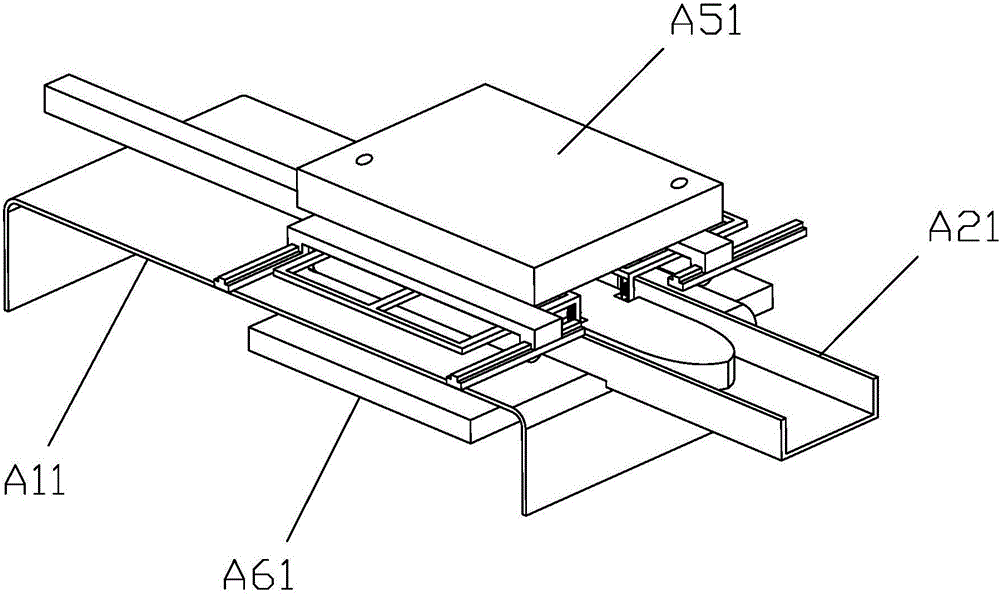

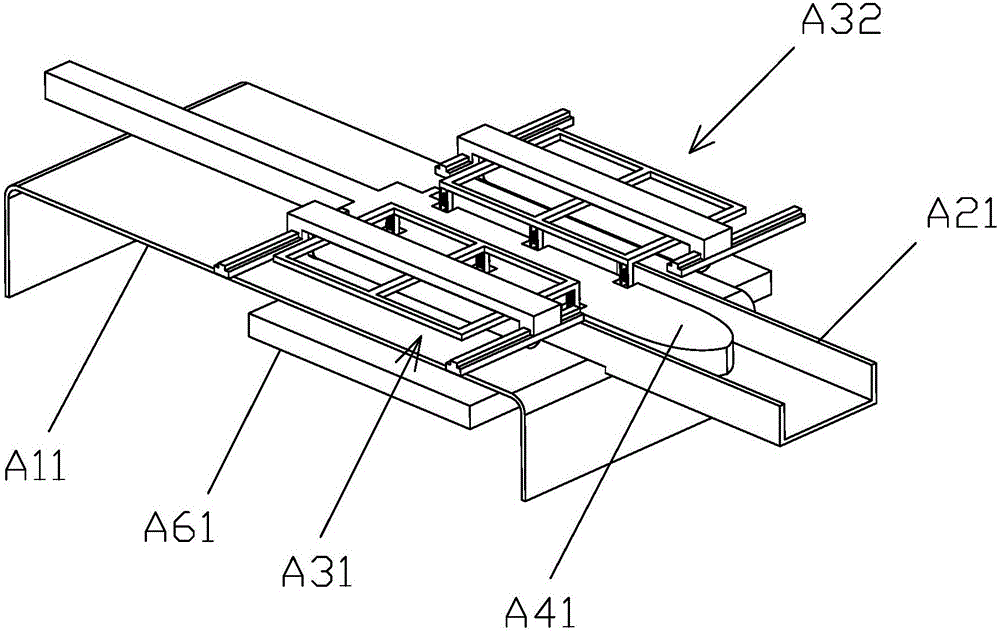

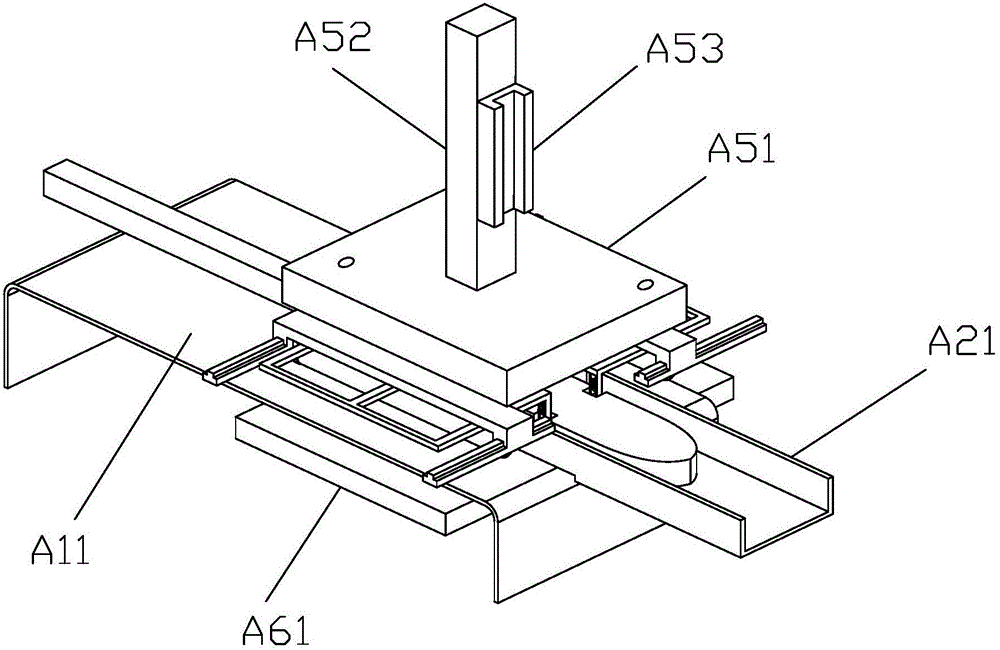

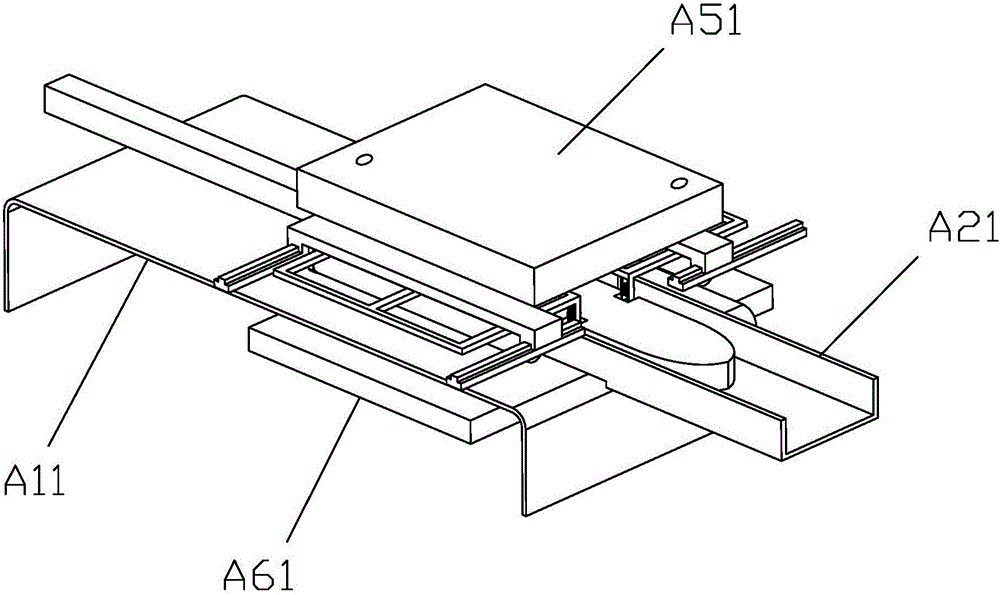

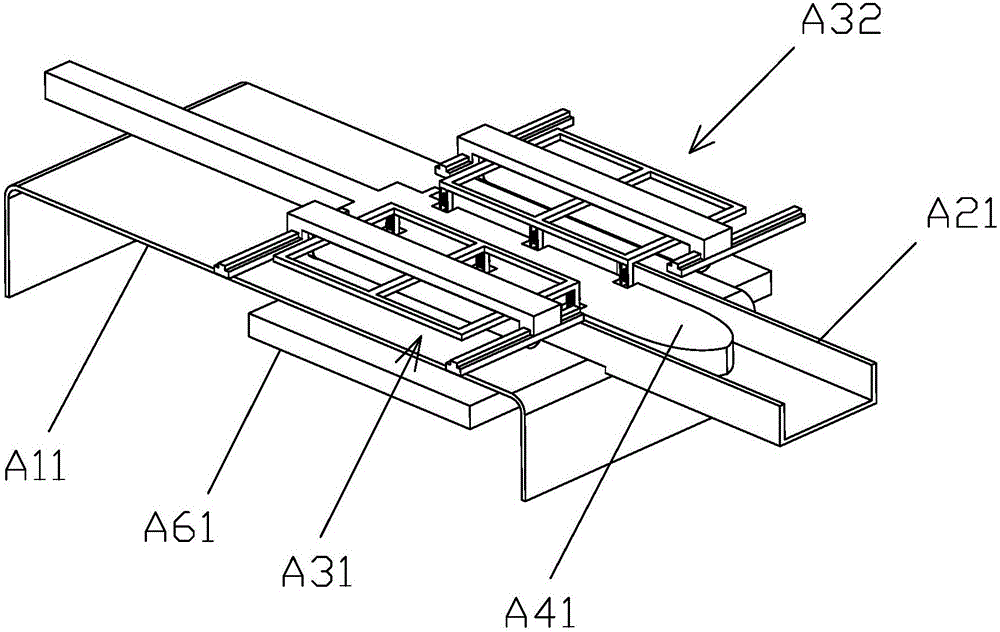

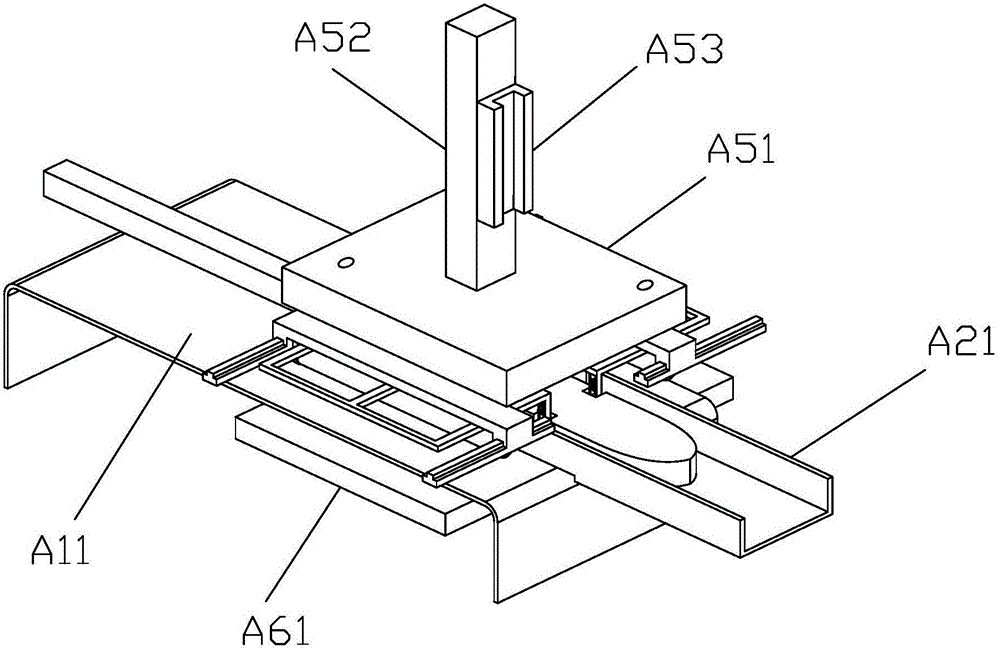

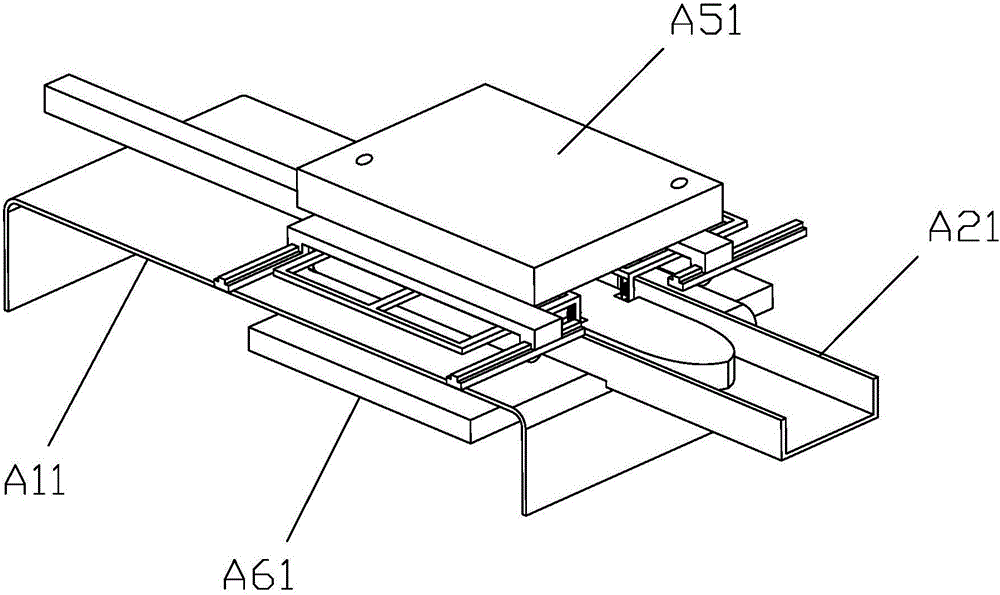

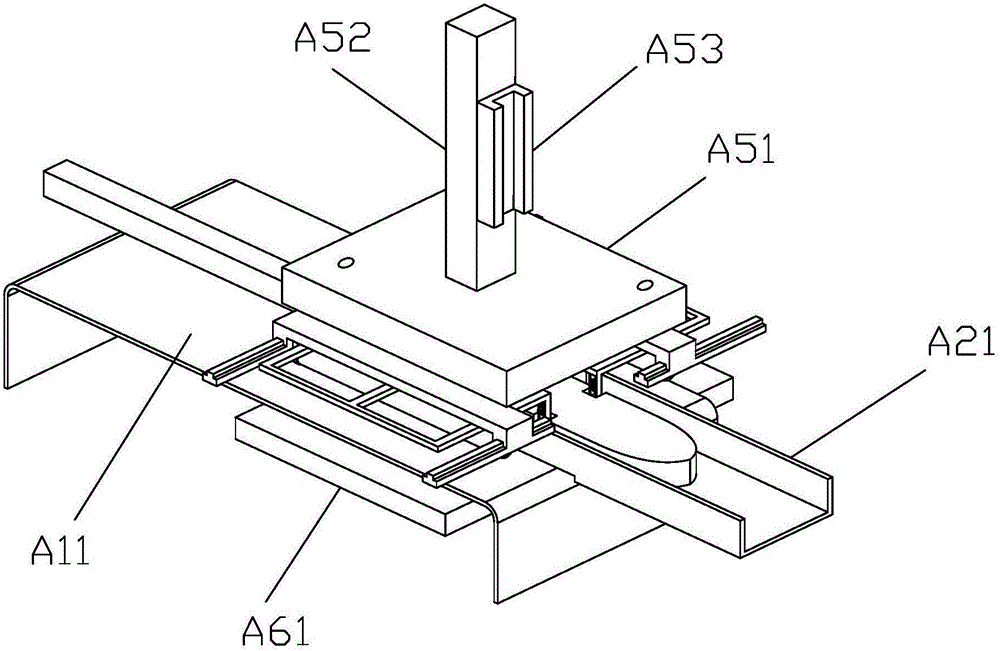

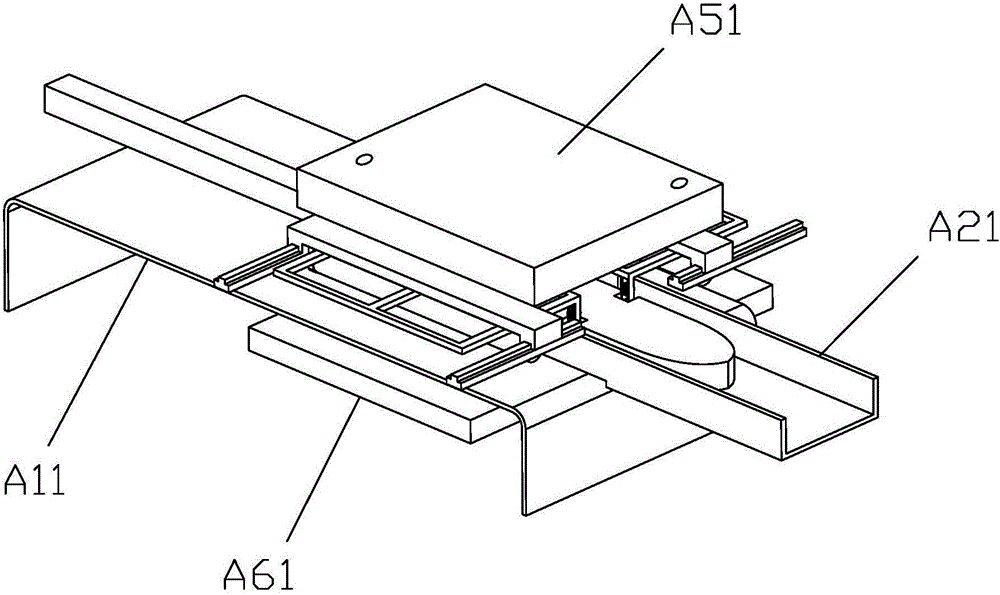

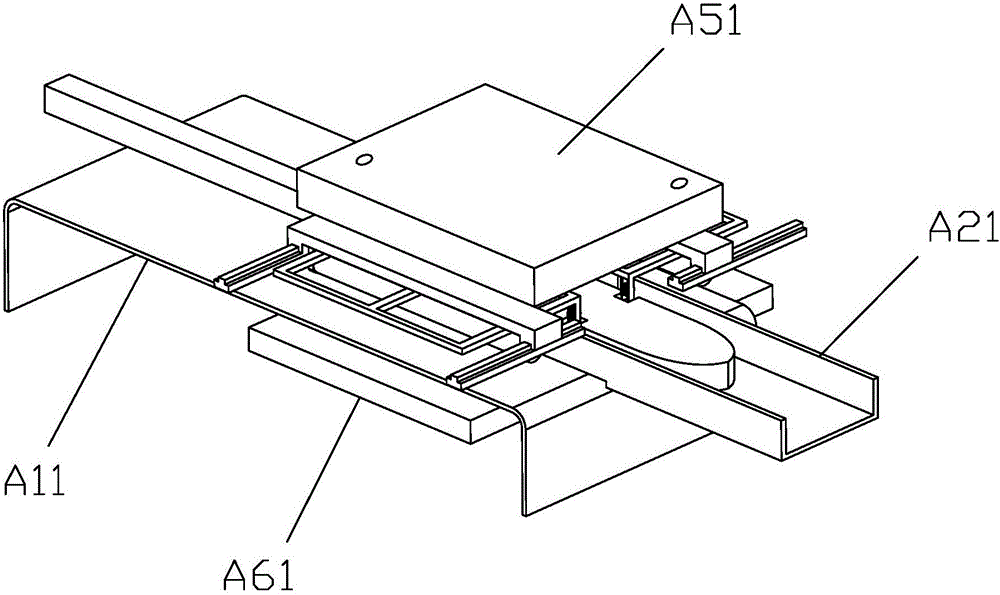

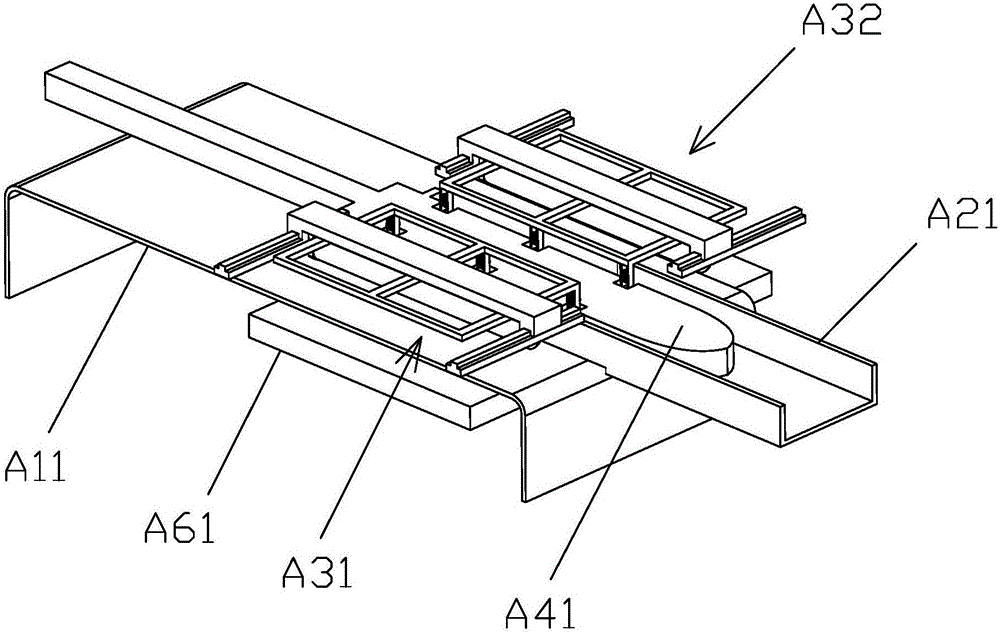

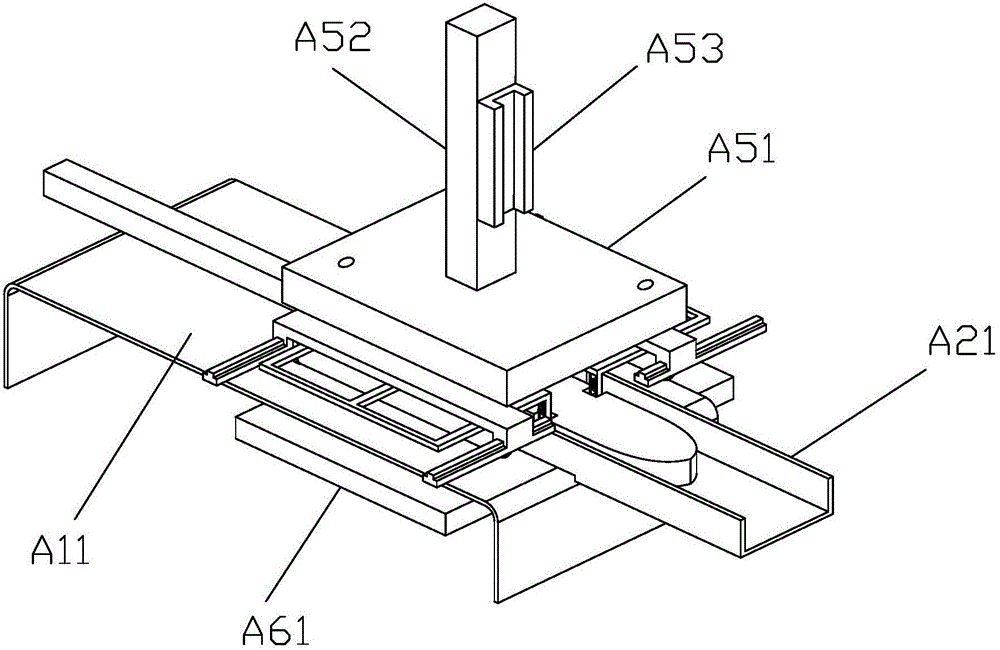

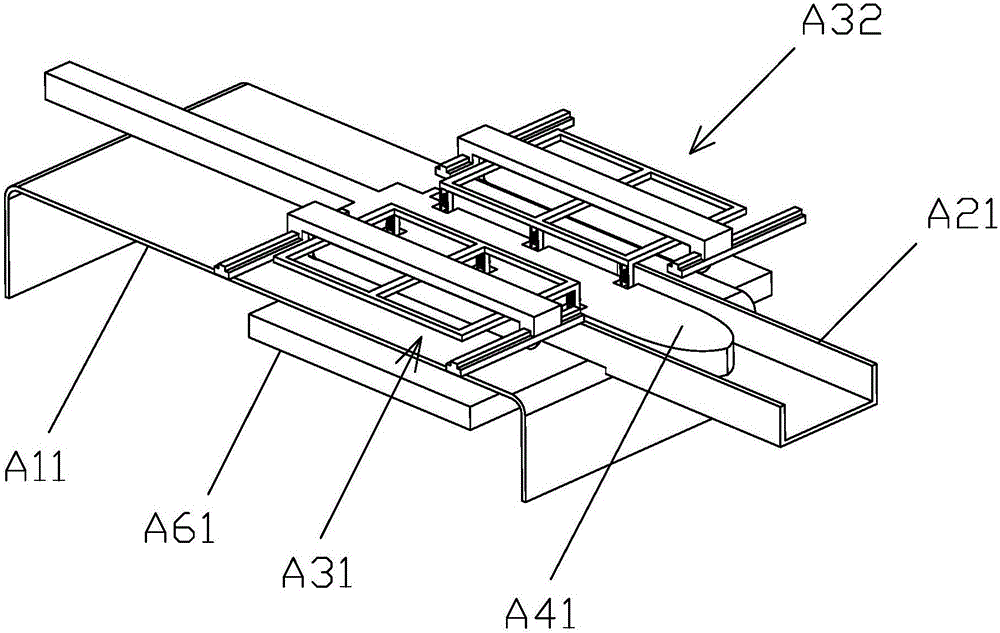

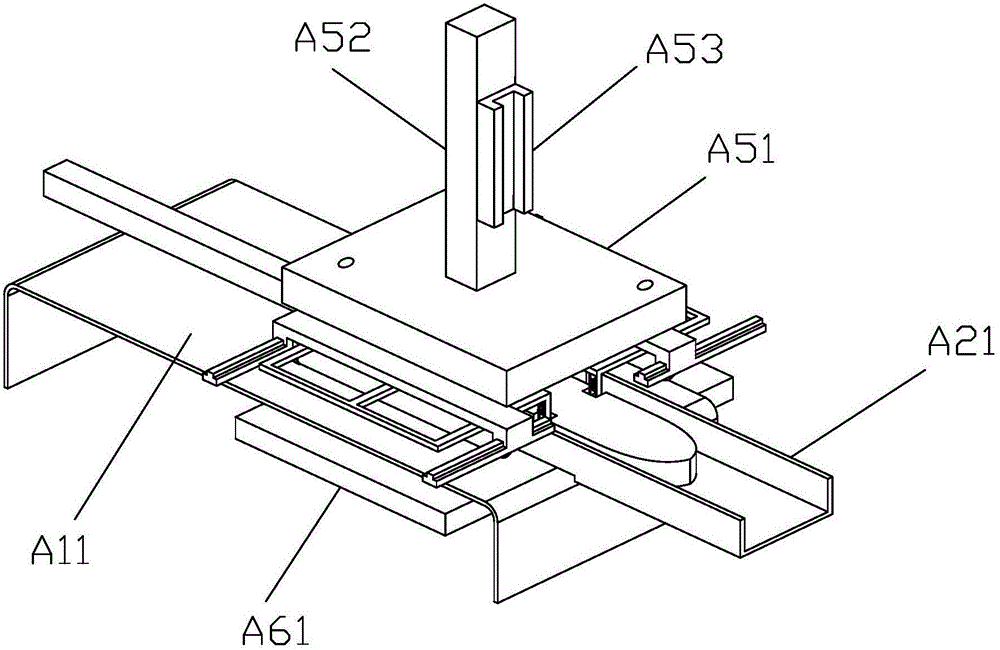

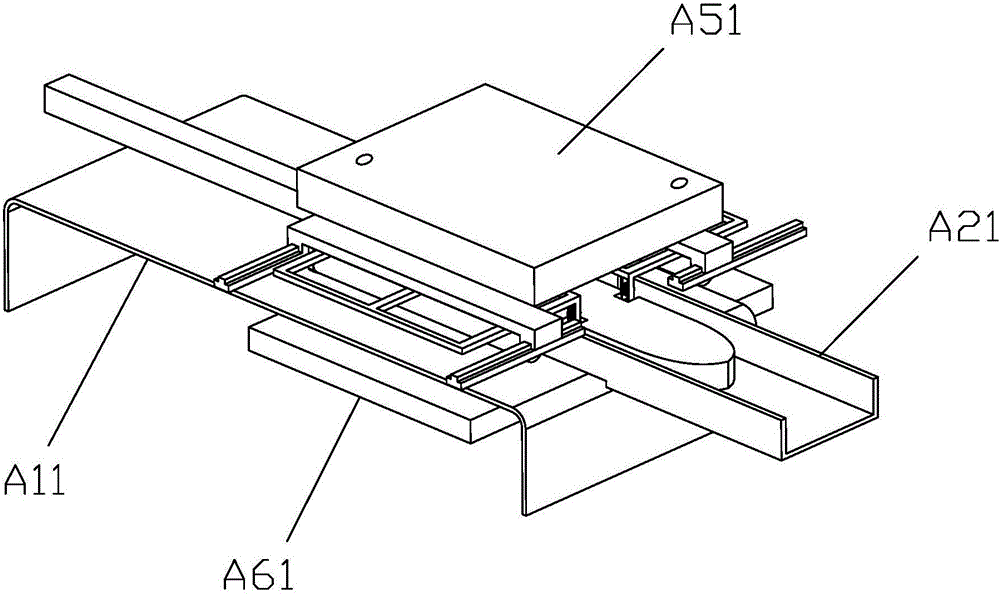

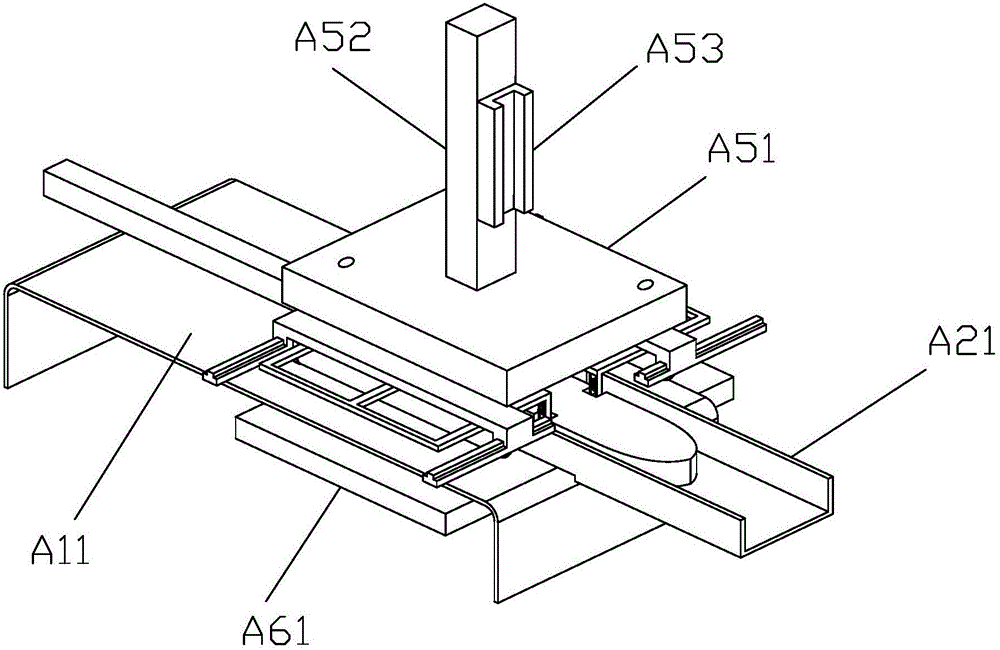

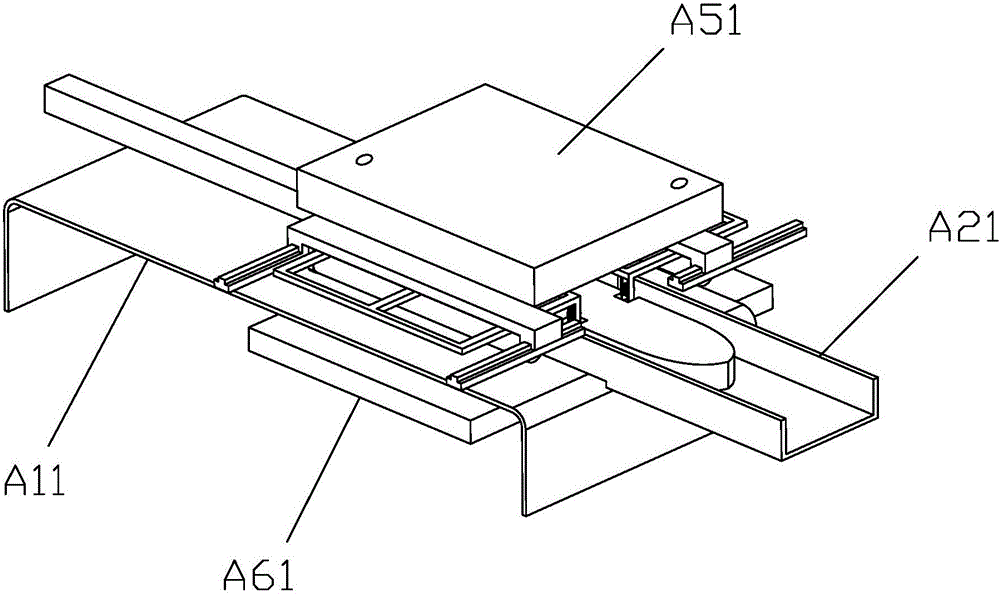

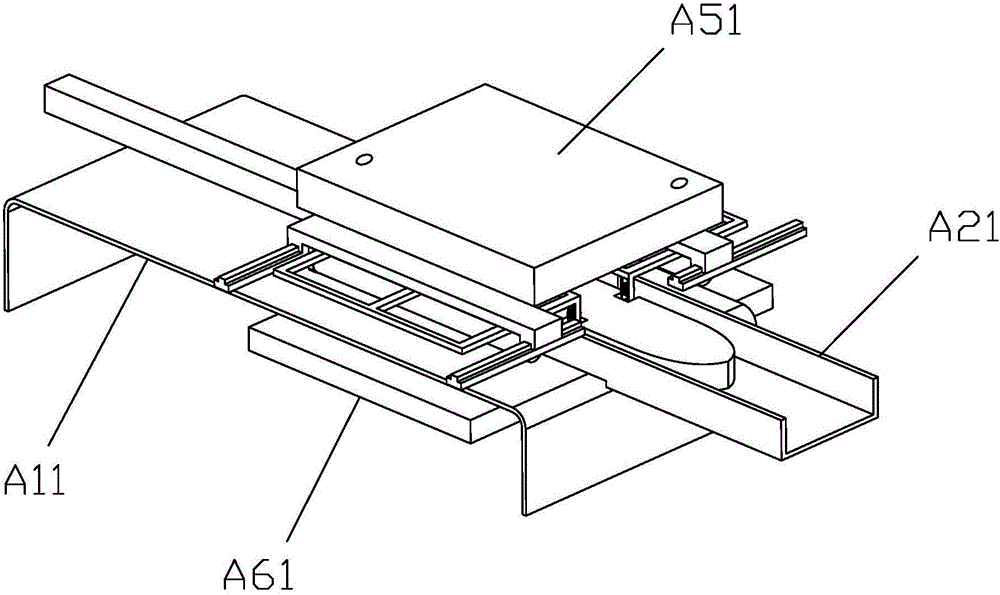

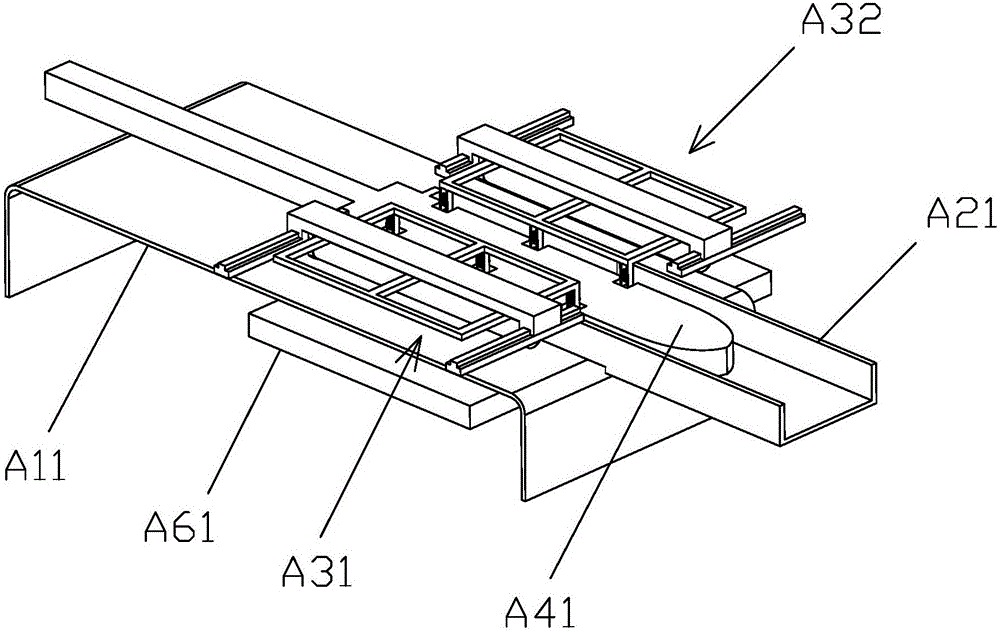

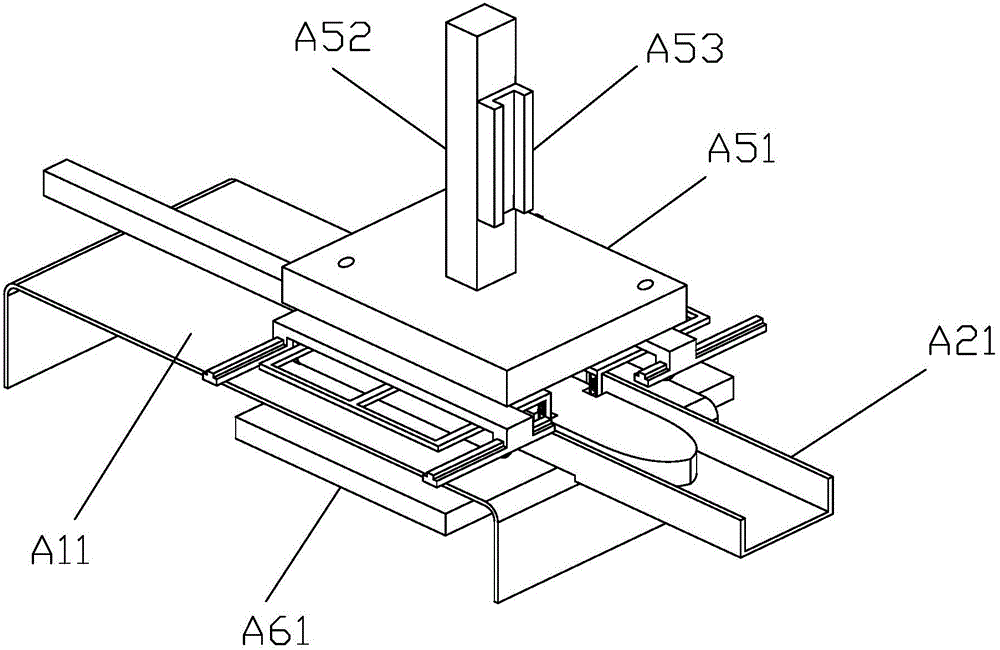

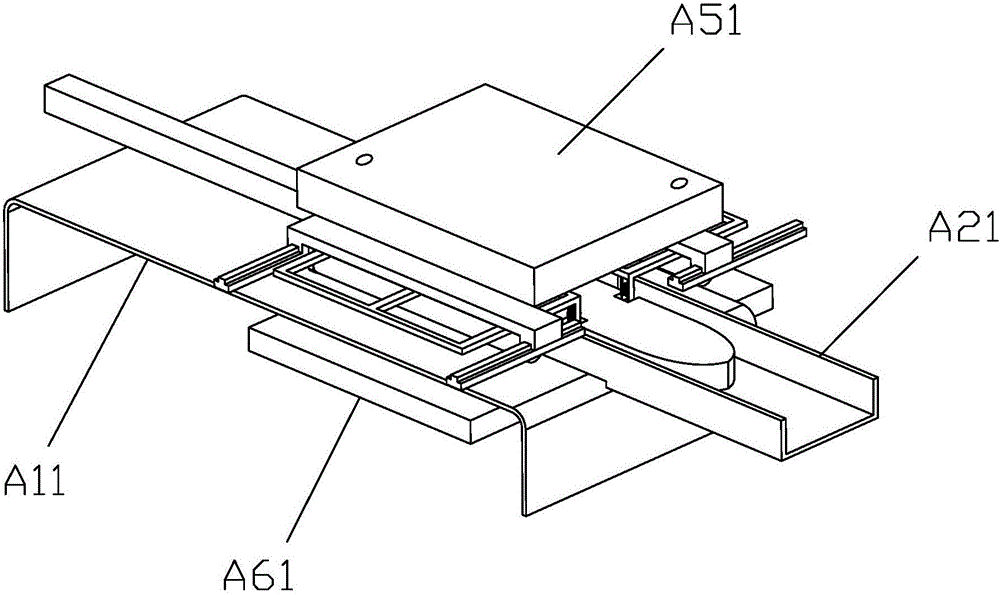

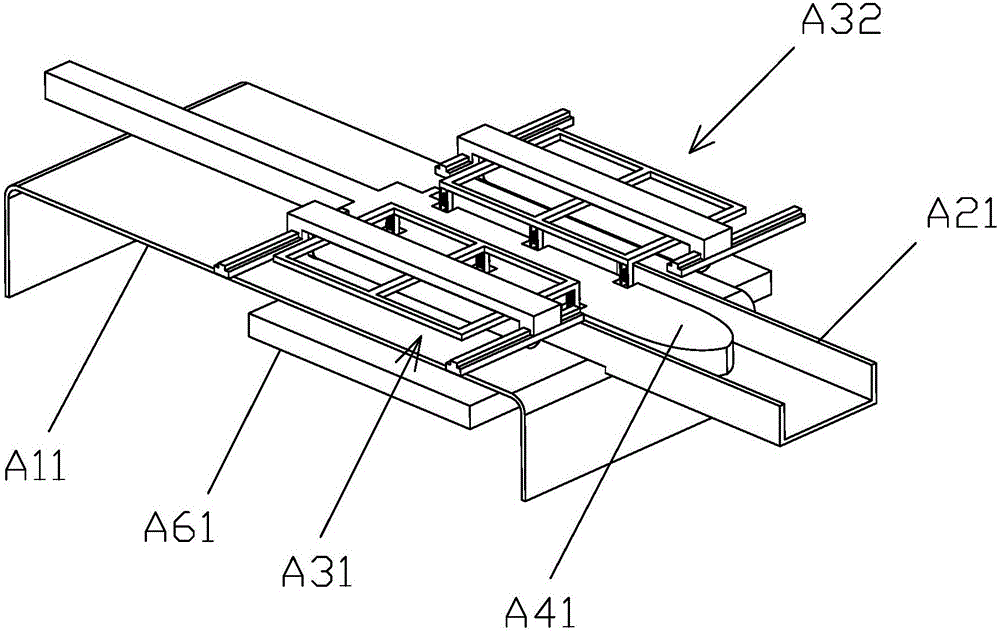

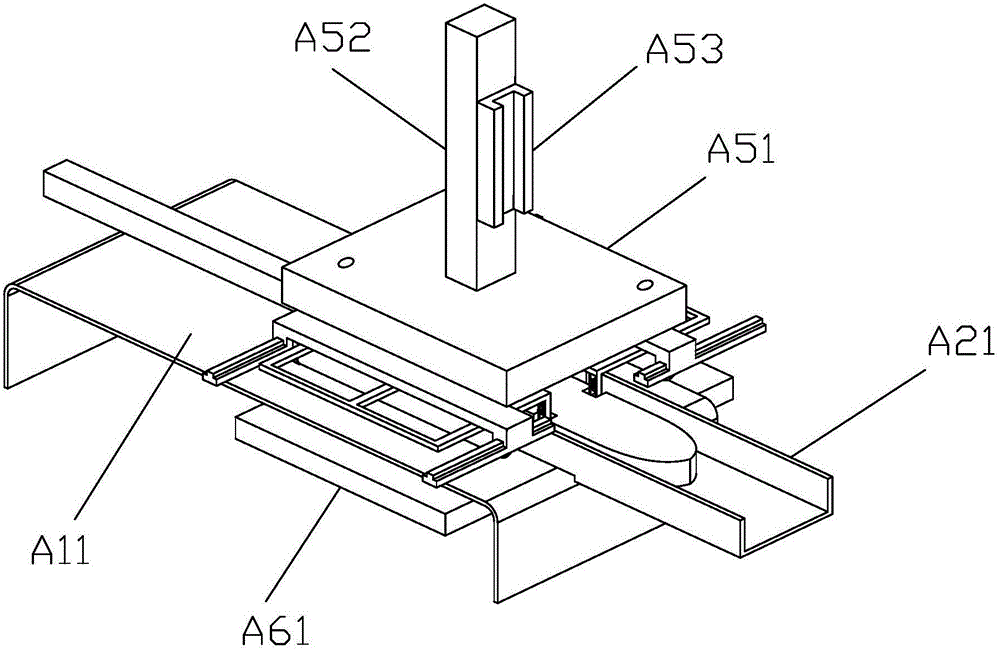

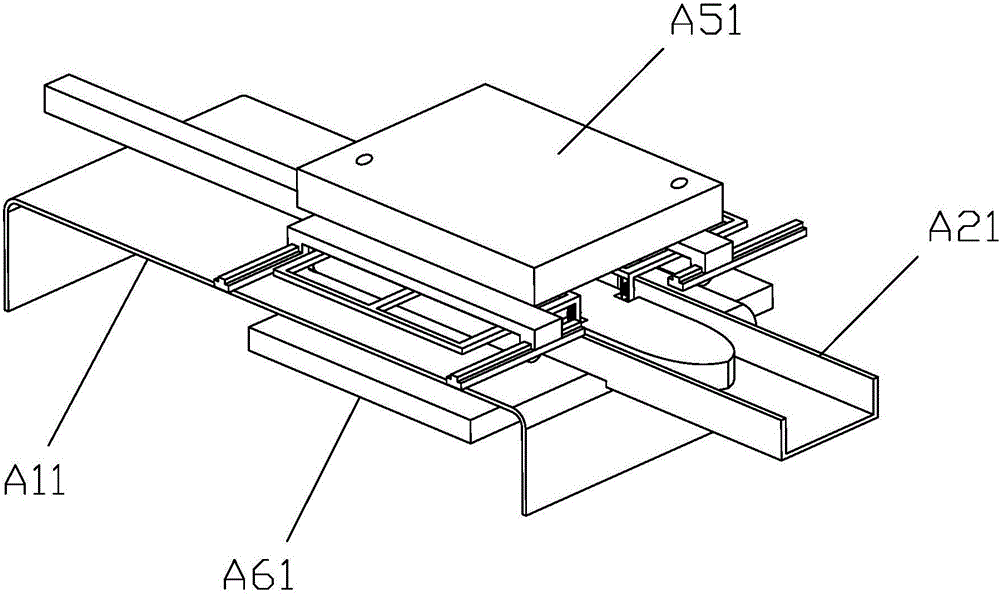

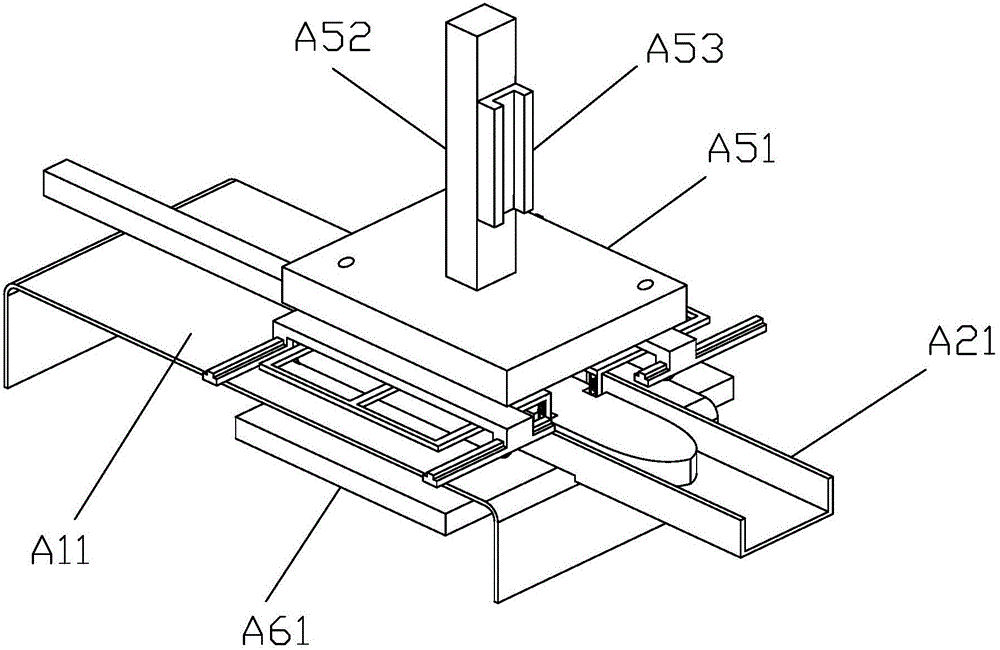

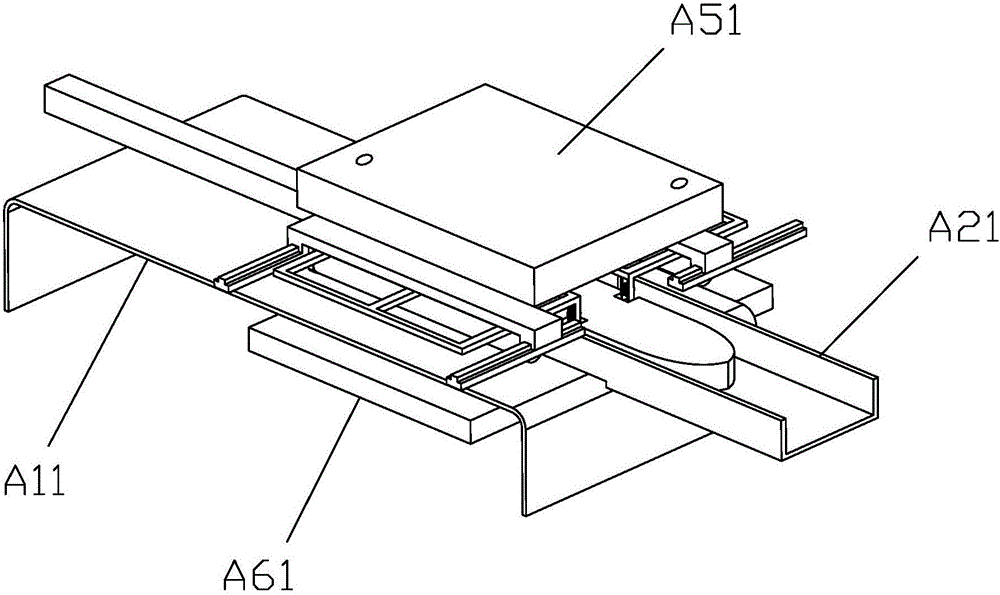

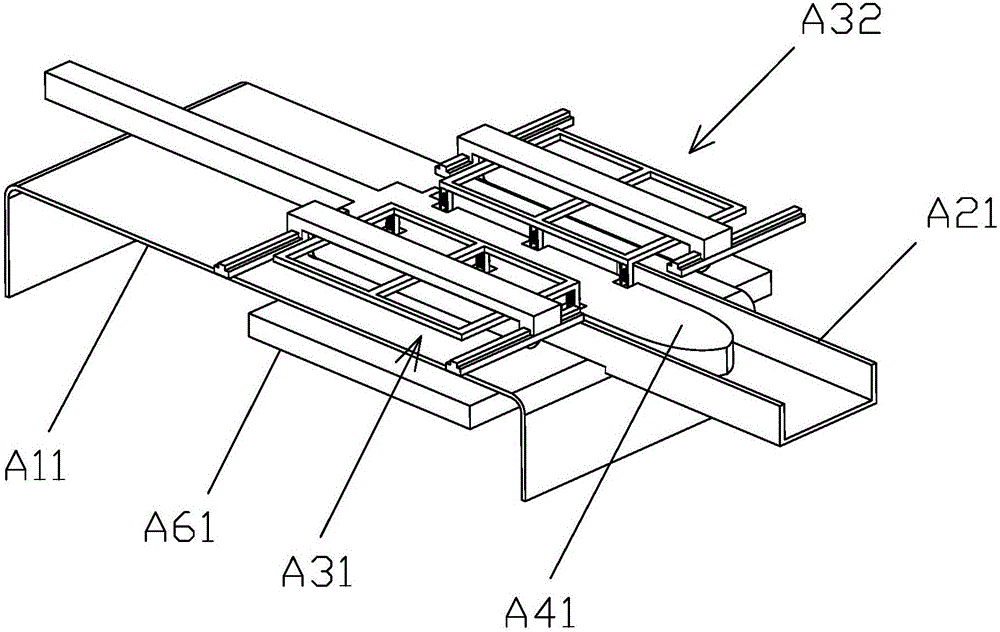

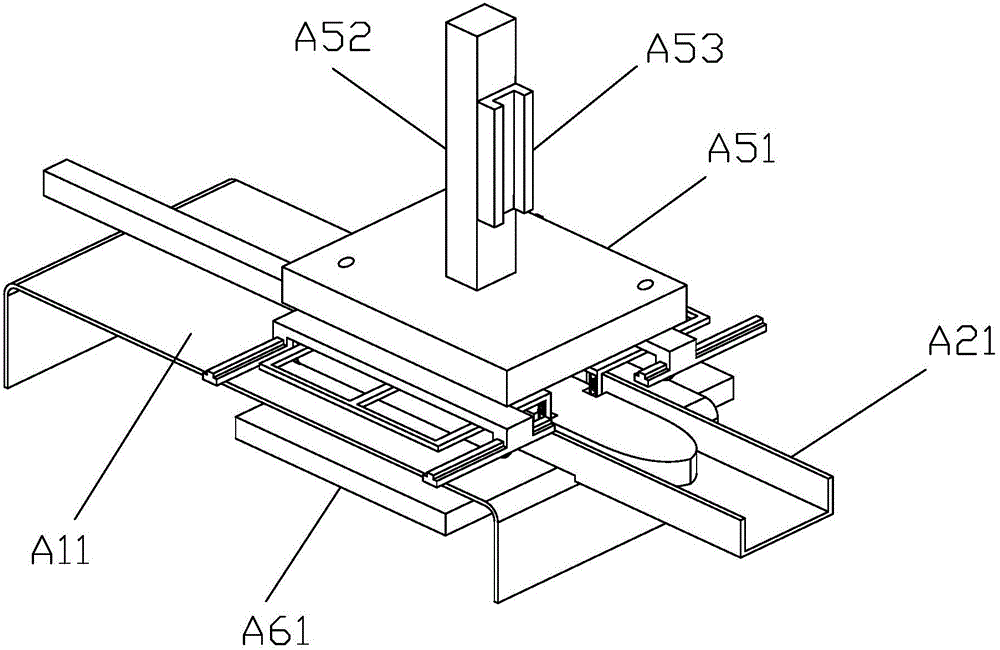

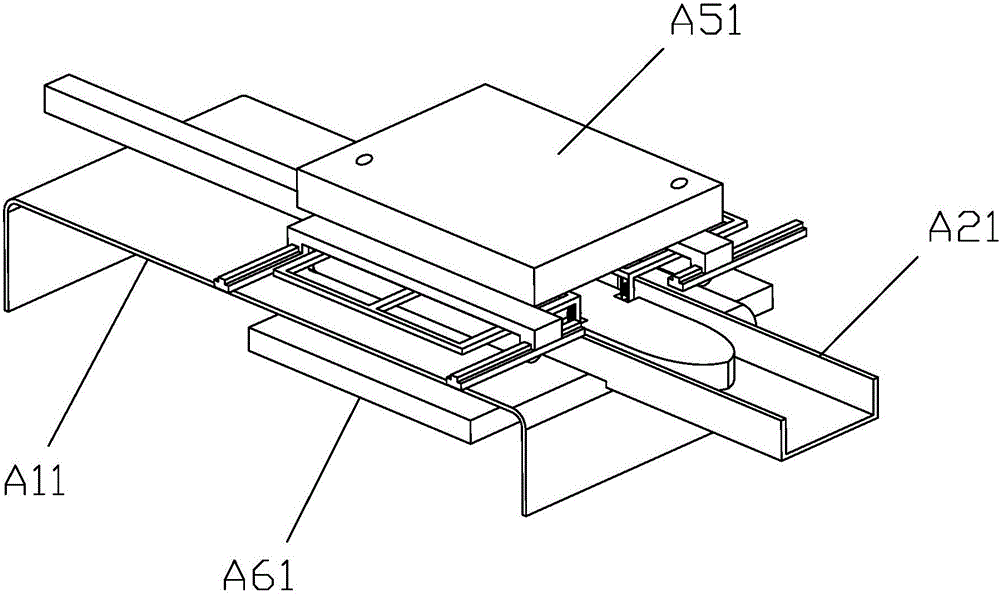

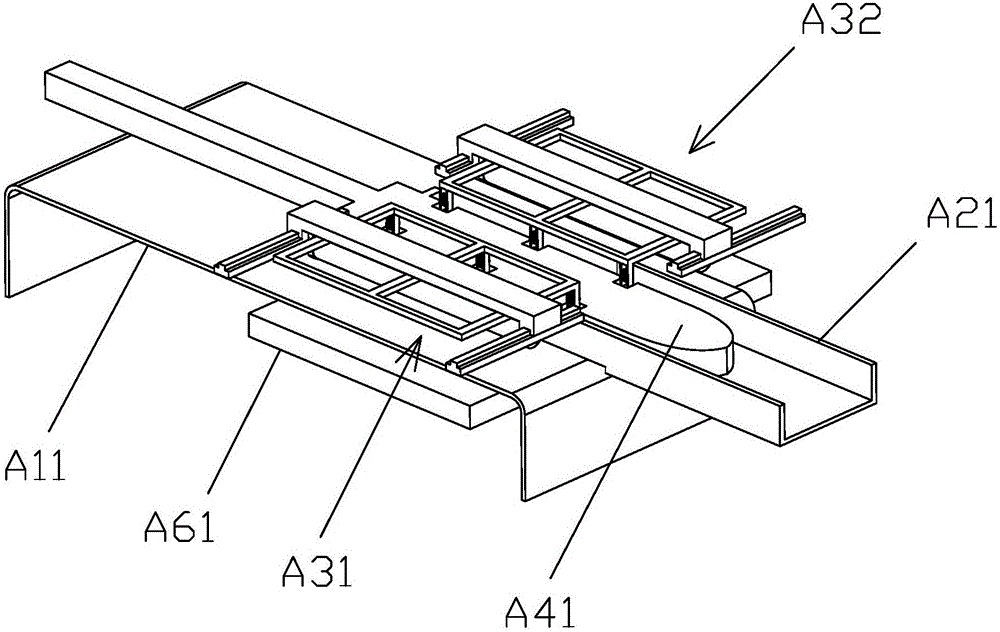

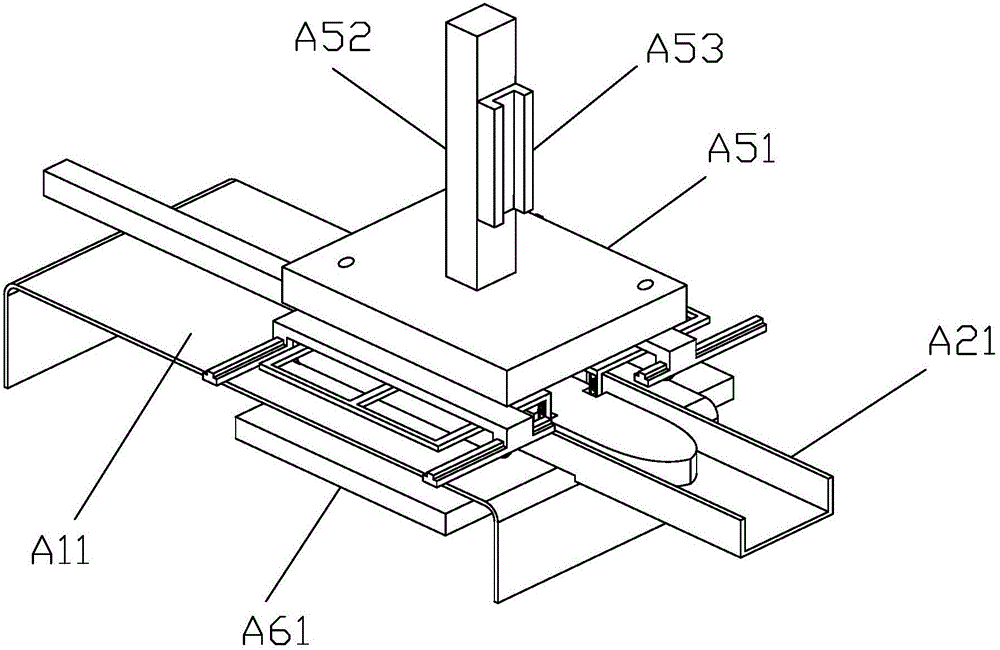

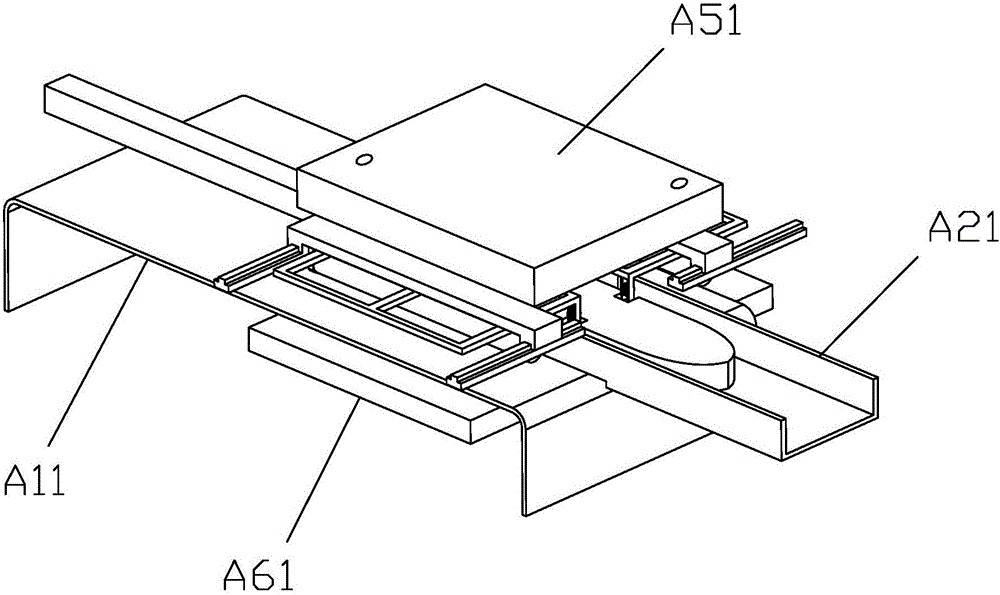

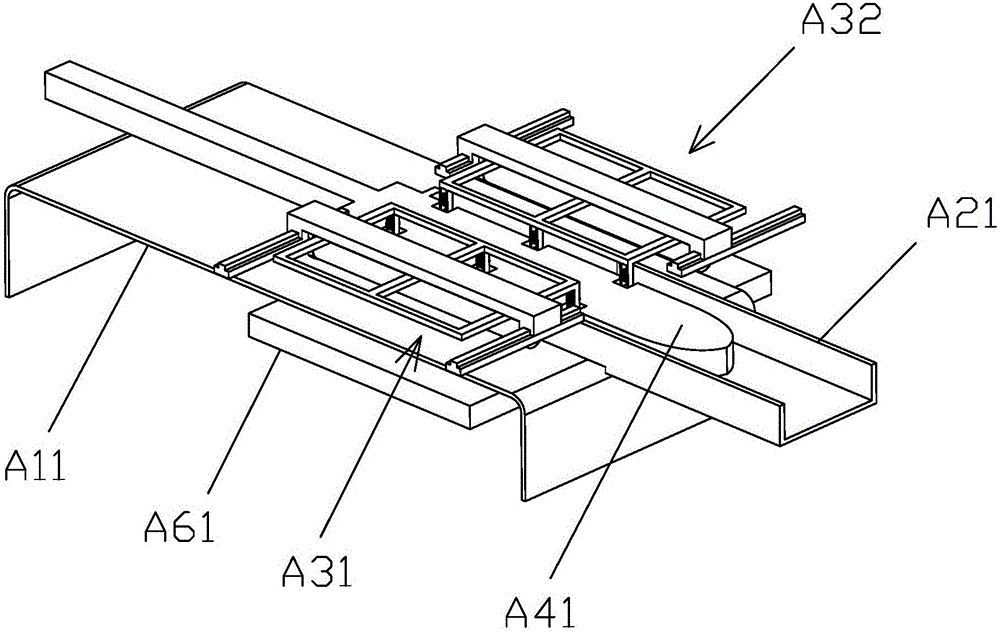

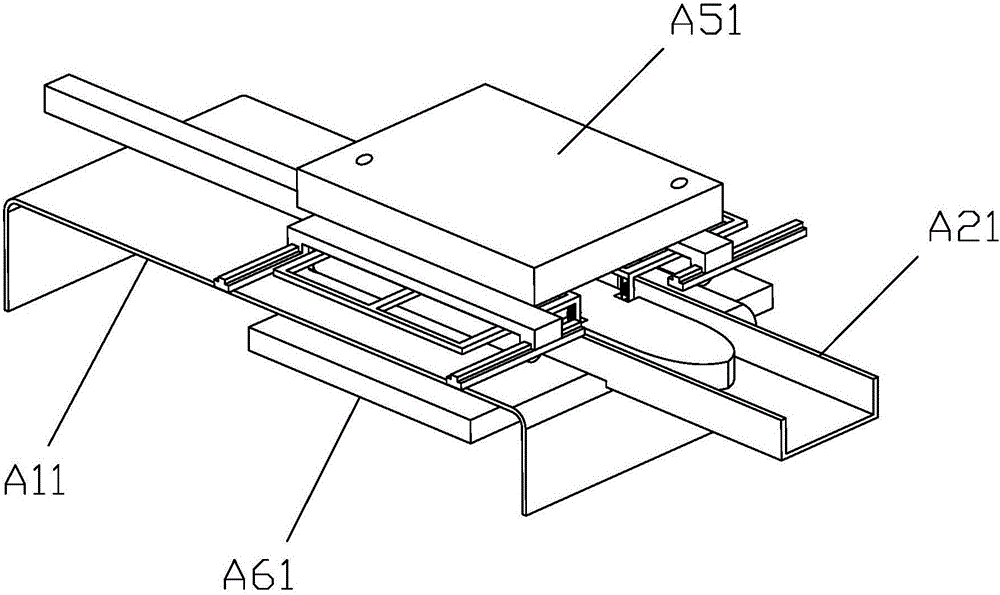

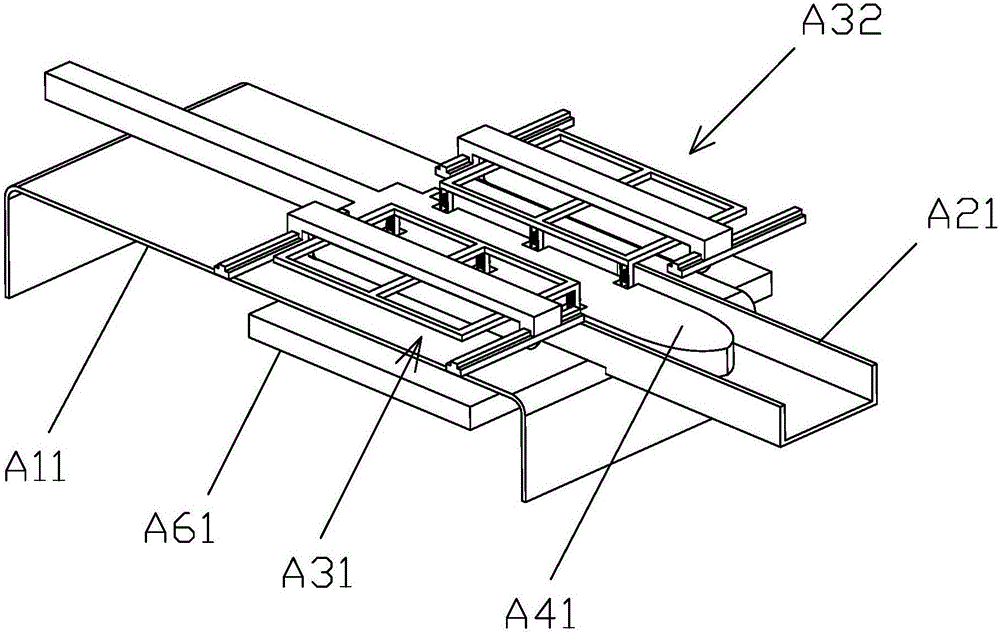

The invention relates to a system for pretreatment of stalk sheaths consisting of a drying rack, a hair removal device and a flattening device, including a hair removal device, a soaking tank, a cooking device, a water washing tank, a drying rack, a flattening device and a pressing device. machine; the groove length direction of the bamboo shell feeding chute is consistent with the conveying direction of the bamboo shell conveyor belt, the inner surface of the groove bottom of the bamboo shell feeding chute is arranged flush with the conveying surface of the upper layer of the bamboo shell conveyor belt, and the bamboo shell feeding trough The two groove walls of the bamboo shell conveyor belt are extended to the inside of the bamboo shell conveyor belt to set the guide extension section, and the bamboo shell conveyor belt is set above the bamboo shell conveyor belt. . The above-mentioned technical scheme can effectively flatten the bamboo shell, and provide reliable support for the processing and utilization of the bamboo shell.

Owner:王寿南

Method for pre-treating culm sheath waste by jointly using steaming device, airing support and flatly-spreading device

InactiveCN105835175AEffective flatteningReliable supportWood treatment detailsCane mechanical workingEngineeringPre treatment

The invention relates to a method for pre-treating culm sheath waste by jointly using a steaming device, an airing support and a flatly-spreading device. The method includes the steps that the bamboo shells obtained after burr removal are poured into a soaking groove to be soaked for 0.5 h to 2.5 h, and the bamboo shells sufficiently absorb water; the soaked bamboo shells are steamed for 5 min to 8 min, and the steamed bamboo shells are placed into a rinsing bath to be rinsed; the rinsed bamboo shells are naturally aired on an airing support so as to enable the bamboo shell water content to drop to about 18% to 20%; and then the bamboo shells are fed to the flatly-spreading device to be flatly spread, and the flatly-spread bamboo shells are stacked and bundled to be pressed and neatened. According to the above technical scheme, the bamboo shells can be effectively spread flatly, and reliable supports are provided for machining and using of the bamboo shells.

Owner:王寿南

Operating method for jointly pretreating culm sheath wastes by adopting boiling device, drying rack and flattening device

InactiveCN105835161AEffective flatteningReliable supportWood treatment detailsCane mechanical workingEngineeringWinch

The invention relates to an operating method for jointly pretreating culm sheath wastes by adopting a boiling device, a drying rack and a flattening device. The operating method comprises the following steps of pouring bamboo shells subjected to wool removal into a soaking tank, soaking for 0.5 to 2.5 hours, and enabling the bamboo shells to sufficiently absorb water; and boiling the soaked bamboo shells for 5 to 8 minutes, and placing the boiled bamboo shells into a rinsing bath for cleaning, wherein the boiling device comprises a boiling drum and an annular guide rail arranged above the boiling drum; a mesh separating board is arranged in the boiling drum; a drum chamber of the boiling drum at the upper part of the mesh separating board is used for boiling the bamboo shells; a heating assembly B is arranged at the lower side of the mesh separation board; a movable trolley is arranged on the annular guide rail; a winch is arranged on the movable trolley and is connected with a fence frame for holding the bamboo shells; the fence frame is formed by splicing various frame bodies; each frame body comprises a frame bottom, a frame cover and a circular side frame wall; and one end of each frame bottom is connected with the corresponding side frame wall in a hinge way. According to the technical scheme, the bamboo shells can be effectively flattened, and reliable support is provided for processing and utilization of the bamboo shells.

Owner:王寿南

Method for reusing and treating culm sheath waste by means of hair removal device, steaming device and flattening device

InactiveCN105835154AEffective flatteningReliable supportWood treatment detailsCane mechanical workingHair removalFuel tank

The invention relates to a method for reusing and treating culm sheath waste by means of a hair removal device, a steaming device and a flattening device. The method comprises the steps that naturally flattened and aired bamboo shells are fed into the hair removal device for hair removal; the bamboo shells obtained after hair removal are dumped into a soaking tank to be soaked for 0.5 h to 2.5 h, and the bamboo shells fully absorb water; and the soaked bamboo shells are put into the steaming device to be steamed for 5 min to 8 min, and the steamed bamboo shells are put into a washing tank to be washed. The interior of a hot pressing plate is arranged to be in the shape of a cavity used for containing heat conduction oil. A circulating oil path is formed by the cavity via oil conduction pipes, a conveying pump and an oil storage box. An electric heating assembly is arranged in the oil storage box. Partition plates are arranged in the cavity and divide the cavity into a circuitous runner allowing the heat conduction oil to flow. According to the technical scheme, the bamboo shells can be effectively flattened, and reliable support is provided for machining and utilizing of the bamboo shells.

Owner:王寿南

Treatment system for pretreating bamboo shells by means of combination of hair removal device and flattening device

InactiveCN105835151AEffective flatteningReliable supportWood treatment detailsCane mechanical workingHair removalEngineering

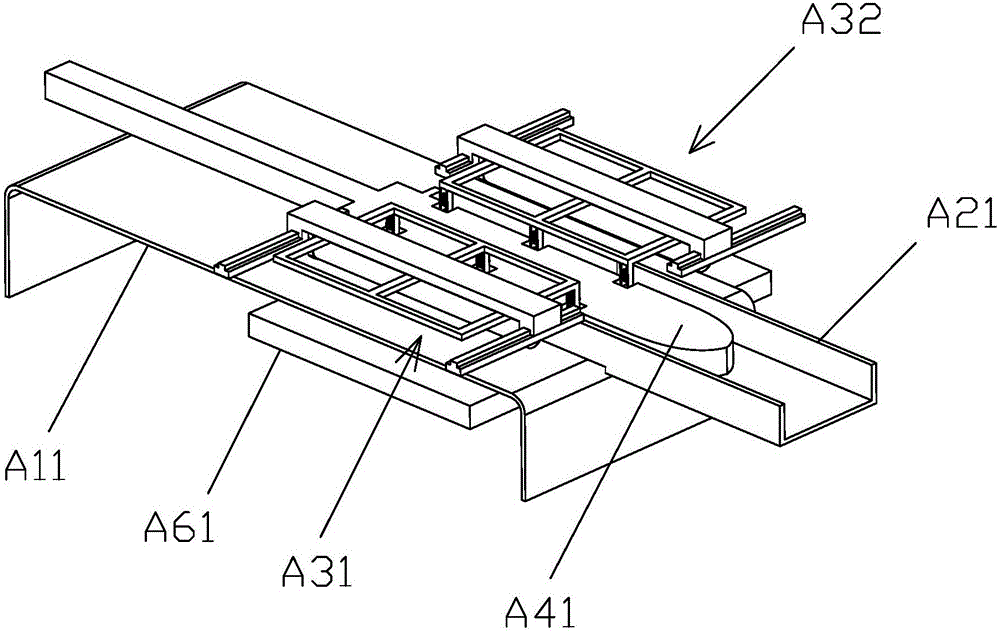

The invention relates to a treatment system for pretreating bamboo shells by means of combination of a hair removal device and a flattening device. The treatment system comprises the hair removal device, a soaking tank, a steaming device, a washing tank, an airing rack, the flattening device and a pressing machine which are sequentially arranged. The hair removal device is used for removing hair on the outer surfaces of the bamboo shells. The soaking tank is used for soaking the bamboo shells obtained after hair removal. The steaming device is used for steaming the soaked bamboo shells. The washing tank is used for washing the steamed bamboo shells. The airing rack is used for airing the washed bamboo shells to lower the water content. The flattening device is used for flattening the aired bamboo shells. The pressing machine is used for stacking and pressing the flattened bamboo shells. The width of a bamboo shell guide plate is smaller than the tank width of a bamboo shell feeding tank. The two sides of the bamboo shell guide plate are each provided with vacancy parts towards the interior of a body. The bamboo shell guide plate is connected with a drive mechanism B and arranged on a rack A in a sliding manner in the tank length direction of the bamboo shell feeding tank. The drive mechanism B adjusts the bamboo shell guide plate to move in the tank length direction of the bamboo shell feeding tank. According to the technical scheme, the bamboo shells can be effectively flattened, and reliable support is provided for machining and utilizing of the bamboo shells.

Owner:王寿南

Equipment for pretreating culm-sheath waste through joint application of stewing device, airing rack and flattening device

InactiveCN106078962AEffective flatteningReliable supportWood treatment detailsCane mechanical workingEngineeringWinch

The invention relates to equipment for pretreating culm-sheath waste through joint application of a stewing device, an airing rack and a flattening device. The equipment comprises a hair removing device, a soaking tank, the stewing device, a rinsing tank, the airing rack, the flattening device and a press trimming machine. Each frame comprises a frame bottom, a frame cover and a circular side frame wall. One end of each frame bottom is hinged to the corresponding side frame wall. Toggles are arranged at the bottoms of the side frame walls, and insertion pins are inserted into the toggles to lock the frame bottoms. Connecting hooks are uniformly arranged on the periphery of the top of each side frame wall at intervals, connecting buckles are uniformly arranged on the periphery of the bottom of each side frame wall at intervals, and the connecting hooks and the connecting buckles are arranged correspondingly. The adjacent frames are connected through the connecting hooks and the connecting buckles in a locked mode. Partition barriers are arranged in the frames for partition. Winches are used for hoisting fence frames. According to the technical scheme, bamboo shells can be effectively flattened, and reliable support is provided for processing and utilizing of the bamboo shells.

Owner:王寿南

Culm-sheath waste processing system composed of airing rack, hair removing device and flattening device

InactiveCN106078963AEffective flatteningReliable supportWood treatment detailsCane mechanical workingWaste processingPulp and paper industry

The invention relates to a culm-sheath waste processing system composed of an airing rack, a hair removing device and a flattening device. The culm-sheath waste processing system comprises the hair removing device, a soaking tank, a stewing device, a rinsing tank, the airing rack, the flattening device and a press trimming machine. The hair removing device comprises a rack B and a hair removing roller obliquely arranged on the rack B. The two ends of the hair removing roller are provided with a feeding inlet and a discharging outlet correspondingly. Protruding ribs are arranged on the inner wall face of the hair removing roller. The length direction of the protruding ribs and the length direction of the hair removing roller are consistent. The protruding ribs are arranged on the inner wall of the hair removing roller in the length direction of the hair removing roller in a layered mode. The protruding ribs of the adjacent layers are arranged in spaced and staggered modes. The hair removing roller is connected with a driving mechanism E. According to the technical scheme, bamboo shells can be effectively flattened, and reliable support is provided for processing and utilizing of the bamboo shells.

Owner:王寿南

Method for jointly pretreating bamboo shells by adopting drying rack and flattening device

InactiveCN105835166AEffective flatteningReliable supportWood treatment detailsCane mechanical workingEngineeringWater content

The invention relates to a method for jointly pretreating bamboo shells by adopting a drying rack and a flattening device. The method comprises the following steps of naturally drying cleaned bamboo shells on the drying rack, and enabling the water content of the bamboo shells to be reduced to be about 18 to 20 percent; and then conveying to the flattening device for flattening, stacking the flattened bamboo shells into bundles, and subsequently pressing. The drying rack comprises a rack F, wherein a supporting tabletop arranged in a stepped shape is arranged on the rack F; a water collecting element is arranged on the supporting tabletop and consists of a bent plate body A; the plate body A comprises a first plate body part and a second plate body part which is arranged by obliquely upwards bending and extending the outer side part of the first plate body part; the first plate body part is obliquely arranged; and the height of the outer side of the first plate body part is greater than that of the inner side of the first plate body part. According to the technical scheme, the bamboo shells can be effectively flattened, and reliable support is provided for processing and utilization of the bamboo shells.

Owner:王寿南

Treatment method for pre-treating bamboo shells by jointly using airing support and flatly-spreading device

InactiveCN105835176AFlat and reliableImprove processing efficiencyWood treatment detailsCane mechanical workingPre treatmentEngineering

The invention relates to a treatment method for pre-treating bamboo shells by jointly using an airing support and a flatly-spreading device. The treatment method comprises a burr removing device, a soaking groove, a steaming device, a rinsing bath, an airing support, a flatly-spreading device and a pressing and neatening machine; the airing support comprises a rack F, supporting table tops distributed in a step shape are arranged on the rack F, and water collecting pieces are arranged on the supporting table tops and are formed by a bent plate body A; the plate body A comprises a first plate body part and a second plate body part which is arranged the side portion of the outer side of the first plate body part in an inclined-and-upwards-extending manner, the first plate body part is arranged in an inclined manner, and the height of the outer side of the first plate body part is larger than the height of the inner side of the first plate body part. According to the above technical scheme, bamboo shells can be effectively spread flatly, and reliable supports are provided for machining and using of the bamboo shells.

Owner:王寿南

Treatment method for pretreating bamboo shells by combining drying rack and flattening device

InactiveCN105835162AFlat and reliableImprove processing efficiencyWood treatment detailsCane mechanical workingEngineeringWater content

The invention relates to a treatment device for pretreating bamboo shells by combining a drying rack and a flattening device. The treatment method comprises the following steps of naturally drying cleaned bamboo shells on the drying rack, and enabling the water content of the bamboo shells to be reduced to be about 18 to 20 percent; and then conveying to the flattening device for flattening, stacking the flattened bamboo shells into bundles, and subsequently pressing. The drying rack comprises a rack F, wherein a supporting tabletop arranged in a stepped shape is arranged on the rack F; a water collecting element is arranged on the supporting tabletop and consists of a bent plate body A; the plate body A comprises a first plate body part and a second plate body part which is arranged by obliquely upwards bending and extending the outer side part of the first plate body part; the first plate body part is obliquely arranged; and the height of the outer side of the first plate body part is greater than that of the inner side of the first plate body part. According to the technical scheme, the bamboo shells can be effectively flattened, and reliable support is provided for processing and utilization of the bamboo shells.

Owner:王寿南

Operation method for treating culmsheath wastes through combination of tomentum removing device, cooking device and leveling device

InactiveCN106078959AEffective flatteningReliable supportWood treatment detailsCane mechanical workingGroove widthMachine utilization

The invention relates to an operation method for treating culmsheath wastes through combination of a tomentum removing device, a cooking device and a leveling device. A bamboo shell which is naturally tedded is conveyed into the tomentum removing device to be subject to tomentum removing; the bamboo shell obtained after tomentum removing is poured into a soaking tank to be soaked for 0.5 h to 2.5 h, and the bamboo shell sufficiently absorbs water; the soaked bamboo shell is placed in the cooking device to be cooked for 5 min to 8 min, and the cooked bamboo shell is put into a washing tank to be cleaned; the width of a bamboo shell guide plate is smaller than the groove width of a bamboo shell feeding groove, gap portions are arranged on the two side portions of the bamboo shell guide plate towards the interior of a body, the bamboo shell guide plate is connected with a drive mechanism B, the bamboo shell guide plate is mounted on a rack A in a sliding manner in the groove length direction of the bamboo shell feeding groove, and the drive mechanism B adjusts the bamboo shell guide plate to move in the groove length direction of the bamboo shell feeding groove; and according to the technical scheme, the bamboo shell can be effectively leveled, and reliable supporting is provided for machining utilization of the bamboo shell.

Owner:王寿南

System adopting stewing device, airing shelf and flattening device in combination pretreatment of culm and sheath wastes

InactiveCN105835172AEffective flatteningReliable supportWood treatment detailsCane mechanical workingEngineeringPre treatment

The invention relates to a system adopting a stewing device, an airing shelf and a flattening device in the combination pretreatment of culm and sheath wastes. The system comprises a dehairing device, a soaking trough, the stewing device, a water washing trough, the airing shelf, the flattening device and a presser, wherein the stewing device comprises a stewing barrel and an annular guide rail arranged above the stewing barrel, and a mesh partition board is arranged in the stewing barrel; a barrel cavity of the stewing barrel, on the mesh partition board, is used for stewing bamboo sheaths, and a heating assembly B is arranged on the lower side of the mesh partition board; a moving trolley is arranged on the annular guide rail, a winch is arranged on the moving trolley, and the winch is connected with a rail frame for holding the bamboo sheaths; the rail frame is formed by splicing frame bodies; and each frame body comprises a frame bottom, a frame cover and a round side frame wall, and one end of the frame bottom is hinged to the side frame wall. The technical scheme can effectively flatten the bamboo sheaths and provide reliable support for the processing and utilization of the bamboo sheaths.

Owner:王寿南

Operation method utilizing airing shelf, dehairing device and flattening device in pretreatment of culms and sheaths

InactiveCN105835171AFlat and reliableImprove processing efficiencyWood treatment detailsCane mechanical workingPre treatmentComputer science

The invention relates to an operation method utilizing an airing shelf, a dehairing device and a flattening device in the pretreatment of culms and sheaths. The operation method comprises the following steps: pouring dehaired bamboo sheaths into a soaking trough and soaking for 0.5 to 2.5h until the bamboo sheaths fully absorb water; stewing the soaked bamboo sheaths for 5-8min, placing the stewed bamboo sheaths into a water washing trough and washing the bamboo sheaths; naturally airing the washed bamboo sheaths on the airing shelf until the water content of the bamboo sheaths is reduced to about 18-20%; then conveying the bamboo sheaths to the flattening device, flattening the bamboo sheaths, and stacking the bamboo sheaths flattened into bundles; and then, pressing the bundles. The trough length direction of a bamboo sheath conveying trough is consistent with the conveying direction of a bamboo sheath conveyor belt, and the flattening device for flattening the bamboo sheaths and a hot pressing mechanism for carrying out hot pressing molding on the bamboo sheaths flattened are arranged above the bamboo sheath conveyor belt. The technical scheme can effectively flatten the bamboo sheaths and provide reliable support for the processing and utilization of the bamboo sheaths.

Owner:王寿南

Culm sheath waste treatment system composed of burr removal device, steaming and stewing device and spreading device

InactiveCN105835148AEffective flatteningReliable supportWood treatment detailsCane mechanical workingHeat conductingFuel tank

The invention relates to a culm sheath waste treatment system composed of a burr removal device, a steaming and stewing device and a spreading device. The culm sheath waste treatment system comprises the burr removal device used for removing burrs on the outer surfaces of bamboo shells, a soaking tank used for soaking the bamboo shells subjected to burr removal, the steaming and stewing device used for steaming and stewing the soaked bamboo shells, a water cleaning tank used for cleaning the steamed and stewed bamboo shells, an airing shelf used for airing the cleaned bamboo shells to decrease the moisture content, the spreading device used for spreading the aired bamboo shells, and a pressing machine used for stacking and pressing the spread bamboo shells which are sequentially arranged, wherein a cavity used for accommodating heat conducting oil is formed in a hot pressing plate; the cavity and an oil storage tank form a circulating oil way through oil guide pipes and a delivery pump; an electric heating component is arranged inside the oil storage tank; partition plates are arranged inside the cavity; and the partition plates divide the cavity into a roundabout runner for allowing the heat conducting oil to flow. According to the technical scheme, the bamboo shells can be effectively spread, and reliable support is provided for processing and utilization of the bamboo shells.

Owner:王寿南

Method for pre-treating bamboo shells through flatly-spreading device

InactiveCN105835174AEffective flatteningReliable supportWood treatment detailsCane mechanical workingGroove widthEngineering

The invention relates to a method for pre-treating bamboo shells through a flatly-spreading device. The washed bamboo shells are naturally aired so as to enable the moisture content of the bamboo shells to drop to about 18% to 20%; and then the flatly-spreading device is adopted for flatly spreading the bamboo shells, the flatly-spread bamboo shells are stacked and bundled, and then pressing and neatening are carried out. A bamboo shell guide plate is located above a bamboo shell conveying belt, the distance between the bamboo shell guide plate and the bamboo shell conveying belt is d1, the thickness of the bamboo shells is d2, and the d1 is larger than the d2; the bamboo shell guide plate and a bamboo shell feeding groove are distributed in sequence, the width of the bamboo shell guide plate is smaller than the groove width of the bamboo shell feeding groove, and notch parts are arranged on the two side parts of the bamboo shell guide plate towards the interior of a body of the bamboo shell guide plate; and the bamboo shell guide plate is connected with a driving mechanism B, the bamboo shell guide plate is installed on a rack A in a sliding manner in the groove length direction of the bamboo shell feeding groove, and the driving mechanism B adjusts the bamboo shell guide plate to move in the groove length direction of the bamboo shell feeding groove. According to the above technical scheme, the bamboo shells can be effectively spread flatly, and reliable supports are provided for machining and using of the bamboo shells.

Owner:王寿南

Pretreating system for quickly treating bamboo shells by using flattening device

InactiveCN105835163AEffective flatteningReliable supportWood treatment detailsCane mechanical workingHeat conductingFuel tank

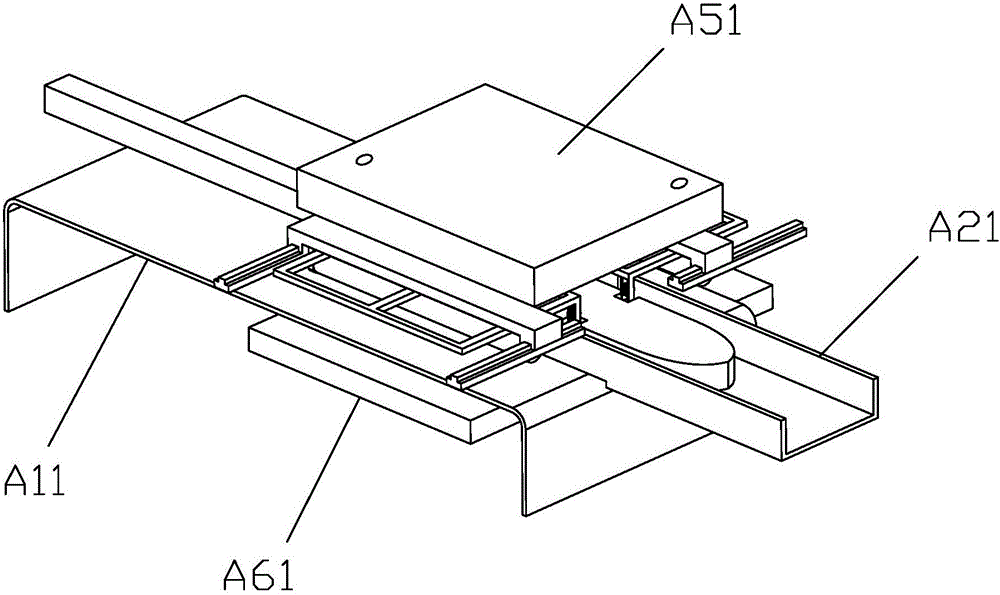

The invention relates to a pretreating system for quickly treating bamboo shells by using a flattening device. The inside of an ironing plate is arranged into a cavity shape for accommodating heat conducting oil; a cavity and an oil storage tank form a circulating oil way through an oil conducting pipe and a delivery pump; an electric heating assembly is arranged in the oil storage tank; and separating boards are arranged in the cavity and divide the cavity into a funicular runner for the heat conducting oil to flow. According to the technical scheme, the bamboo shells can be effectively flattened, and reliable support is provided for processing and utilization of the bamboo shells.

Owner:王寿南

Operation method for pretreating bamboo shells by means of flattening device

InactiveCN105835153AEffective flatteningReliable supportWood treatment detailsCane mechanical workingFuel tankEngineering

The invention relates to an operation method for pretreating bamboo shells by means of a flattening device. The operation method comprises the steps that the washed bamboo shells are naturally aired, the water content of the bamboo shells is lowered to about 18%-20%, then the bamboo shells are flattened in the flattening device, and the flattened bamboo shells are stacked and bundled and then pressed. The interior of a hot pressing plate is arranged to be in the shape of a cavity used for containing heat conduction oil. A circulating oil path is formed by the cavity via oil conduction pipes, a conveying pump and an oil storage box. An electric heating assembly is arranged in the oil storage box. Partition plates are arranged in the cavity and divide the cavity into a circuitous runner allowing the heat conduction oil to flow. According to the technical scheme, the bamboo shells can be effectively flattened, and reliable support is provided for machining and utilizing of the bamboo shells.

Owner:王寿南

Equipment for treating culmsheath wastes in combination with hair removal device, steaming device and flattening device

InactiveCN105835169AEffective flatteningReliable supportWood treatment detailsCane mechanical workingHair removalEngineering

The invention relates to a device for treating stalk sheath waste by combining a depilation device, a cooking device and a flattening device, comprising a depilation device for removing hairs on the outer surface of bamboo shells arranged in sequence, and a soaking tank for soaking the depilated bamboo shells , a cooking device for cooking the soaked bamboo shells, a washing tank for cleaning the boiled bamboo shells, a drying rack for drying the washed bamboo shells to reduce the moisture content, and drying the dried bamboo shells The flattening device is a compacting machine for stacking and pressing the flattened bamboo shells; the width of the bamboo shell guide plate is smaller than the groove width of the bamboo shell feeding trough, and the two sides of the bamboo shell guide plate are respectively facing towards the body. There is a vacant part inside, the bamboo shell guide plate is connected with the driving mechanism B, the bamboo shell guide plate is slid and installed on the frame A along the groove length direction of the bamboo shell feeding trough, and the driving mechanism B adjusts the bamboo shell guide plate to move along the bamboo shell feeding chute. Move in the slot length direction. The above-mentioned technical scheme can effectively flatten the bamboo shells, and provide reliable support for the processing and utilization of the bamboo shells.

Owner:王寿南

Method for treating culm sheath waste by means of airing rack, hair removal device and flattening device

InactiveCN105835157AEffective flatteningReliable supportWood treatment detailsCane mechanical workingHair removalEngineering

The invention relates to a method for treating culm sheath waste by means of an airing rack, a hair removal device and a flattening device. The method comprises the steps that bamboo shells obtained after hair removal are dumped into a soaking tank to be soaked for 0.5 h to 2.5 h, and the bamboo shells fully absorb water; the soaked bamboo shells are steamed for 5 min to 8 min, and the steamed bamboo shells are put into a washing tank to be washed; and the washed bamboo shells are naturally aired on the airing rack, the water content of the bamboo shells is lowered to about 18%-20%, then the bamboo shells are fed to the flattening device to be flattened, and the flattened bamboo shells are stacked and bundled and then pressed. The hair removal device comprises a rack B and a hair removal roller obliquely arranged on the rack B. A feeding opening and a discharging opening are formed in the two ends of the hair removal roller correspondingly. Convex ribs are arranged on the inner wall face of the hair removal roller, and the length direction of the convex ribs is consistent with that of the hair removal roller. The hair removal roller is connected with a drive mechanism E. According to the technical scheme, the bamboo shells can be effectively flattened, and reliable support is provided for machining and utilizing of the bamboo shells.

Owner:王寿南

Treatment method for pre-treating bamboo shells by jointly using steaming plant and flatly-spreading device

InactiveCN105835173AEffective flatteningReliable supportWood treatment detailsCane mechanical workingEngineeringPre treatment

The invention relates to a treatment method for pretreating bamboo shells by combining a steaming device and a flattening device, comprising pouring the depilated bamboo shells into a soaking tank for 0.5-2.5 hours to make the bamboo shells fully absorb water; soaking the soaked bamboo shells The shells are put into the steaming device and boiled for 5-8 minutes, and the boiled bamboo shells are put into the washing tank for cleaning; the frame body includes the frame bottom, the frame cover and the circular side frame wall, and one end of the frame bottom is hingedly connected with the side frame wall , the bottom of the side frame wall is provided with a latch, and a plug is inserted into the latch to lock the bottom of the frame. Connecting hooks are evenly spaced on the outer periphery of the top of the side frame wall, and connecting buckles are evenly spaced on the outer periphery of the bottom of the side frame wall. The connecting hook and the connecting buckle Correspondingly arranged, the adjacent frames are locked and connected by connecting hooks and connecting buckles, partitions are set in the frames to separate, and the hoist lifts the frames. The above-mentioned technical scheme can effectively flatten the bamboo shell, and provide reliable support for the processing and utilization of the bamboo shell.

Owner:王寿南

Novel technology for preprocessing bamboo sheaths utilizing cooking device, airing frame and flattening device

InactiveCN106078957AEffective flatteningReliable supportWood treatment detailsCane mechanical workingFuel tankEngineering

The invention relates to a novel technology for preprocessing bamboo sheaths utilizing a cooking device, an airing frame and a flattening device. The technology comprises the following steps of pouring dehaired bamboo casings into a soaking tank, and performing soaking for 0.5-2.5h, so that the bamboo casings fully absorb water; cooking the soaked bamboo casings for 5-8 min; and placing the cooked bamboo casings in a washing tank, and performing cleaning. An empty cavity for accommodating heat transfer oil is formed in a blanching pressing plate; a circulation oil circuit is formed by the empty cavity and an oil storing tank through an oil conduit and a transporting pump; an electrical heating assemble is arranged in the oil storing tank; and baffles are arranged in the empty cavity, and divide the empty cavity into a roundabout passageway allowing the heat transfer oil to flow. According to the technical scheme of the technology disclosed by the invention, bamboo casings can be effectively flattened, and reliable support for the processing and the utilization of the bamboo casings is provided.

Owner:王寿南

Method for quickly flattening bamboo shells

InactiveCN105835164AFlat and reliableImprove processing efficiencyCane mechanical workingReed/straw treatmentEngineering

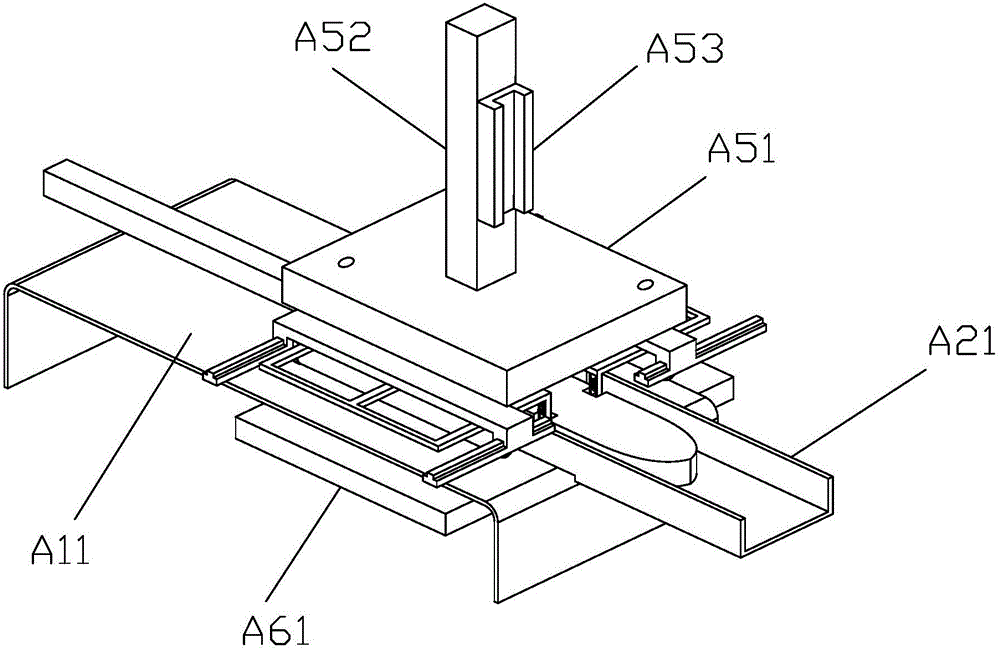

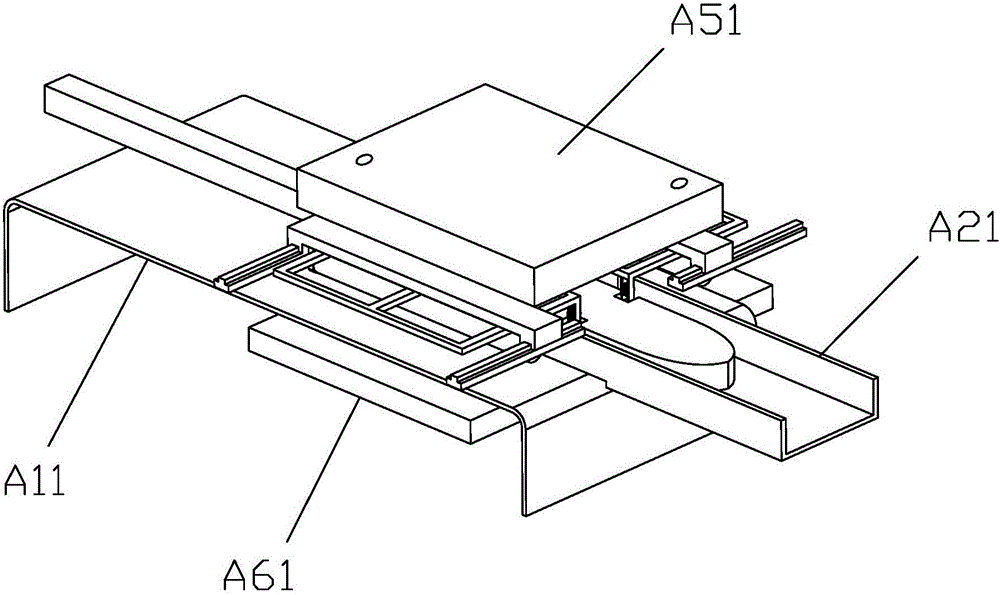

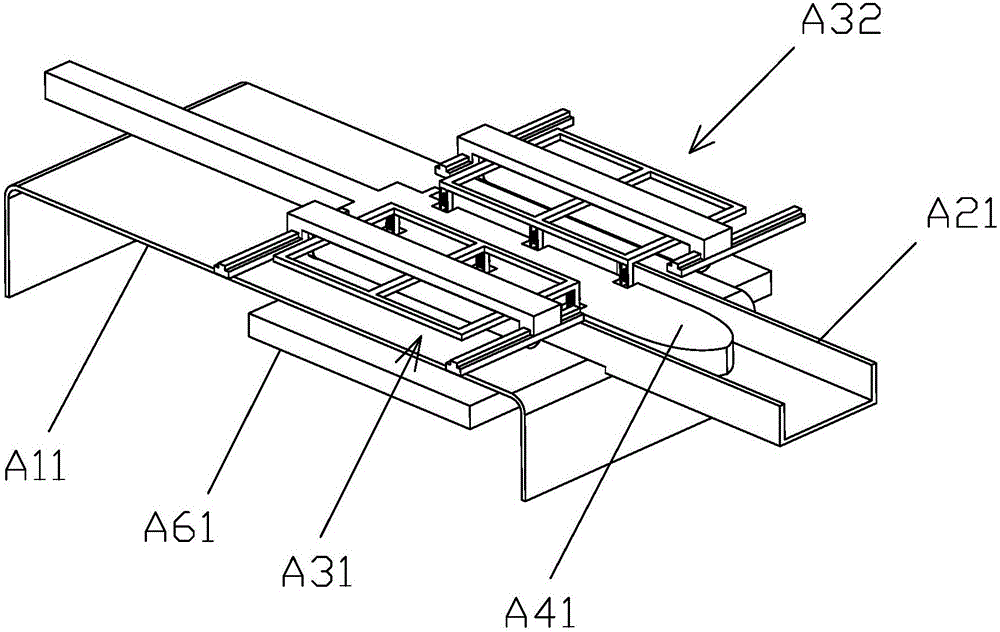

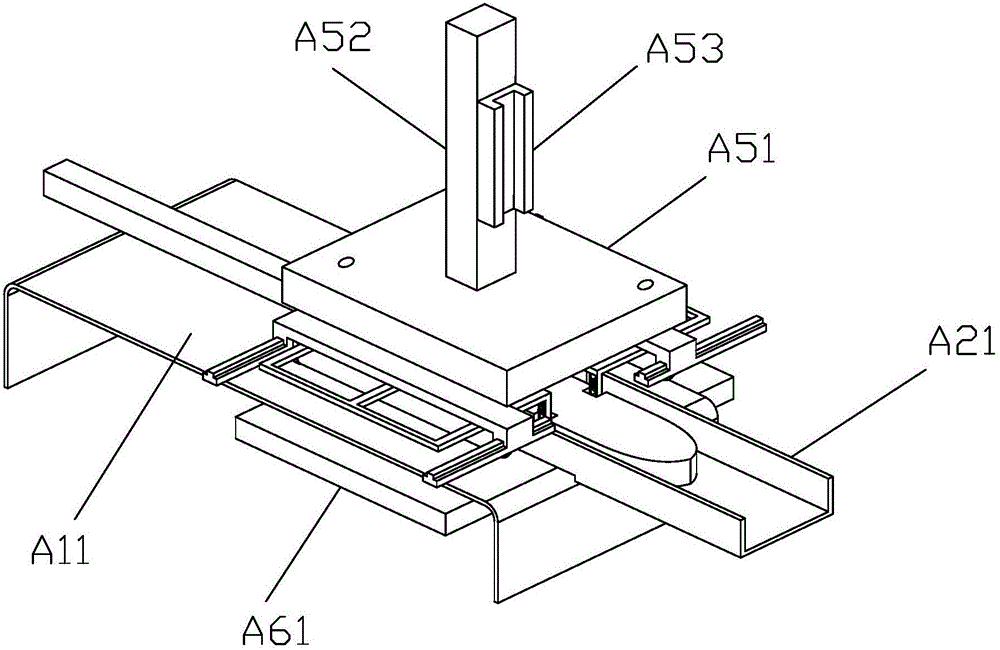

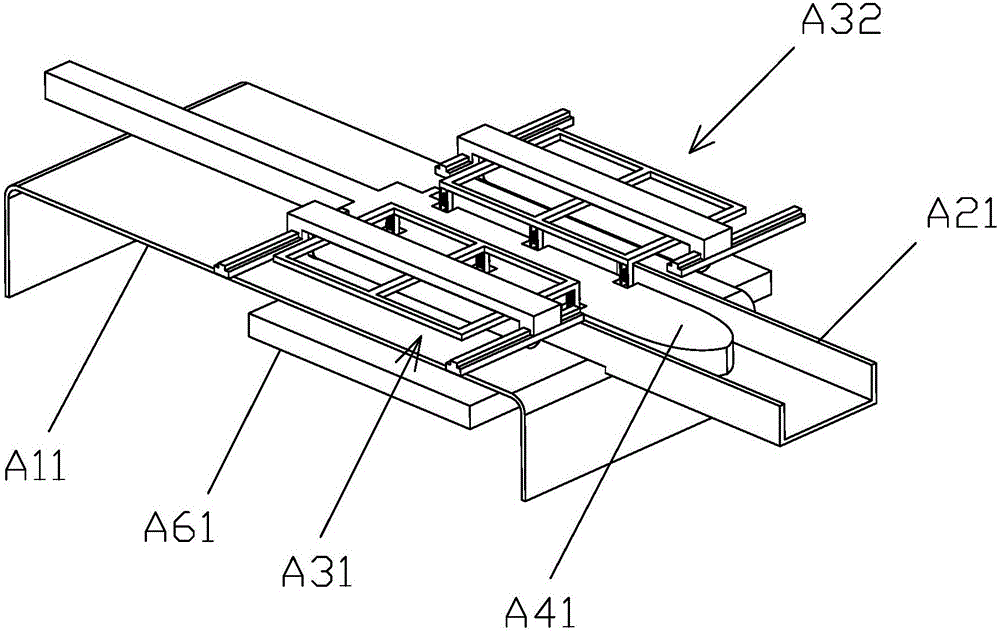

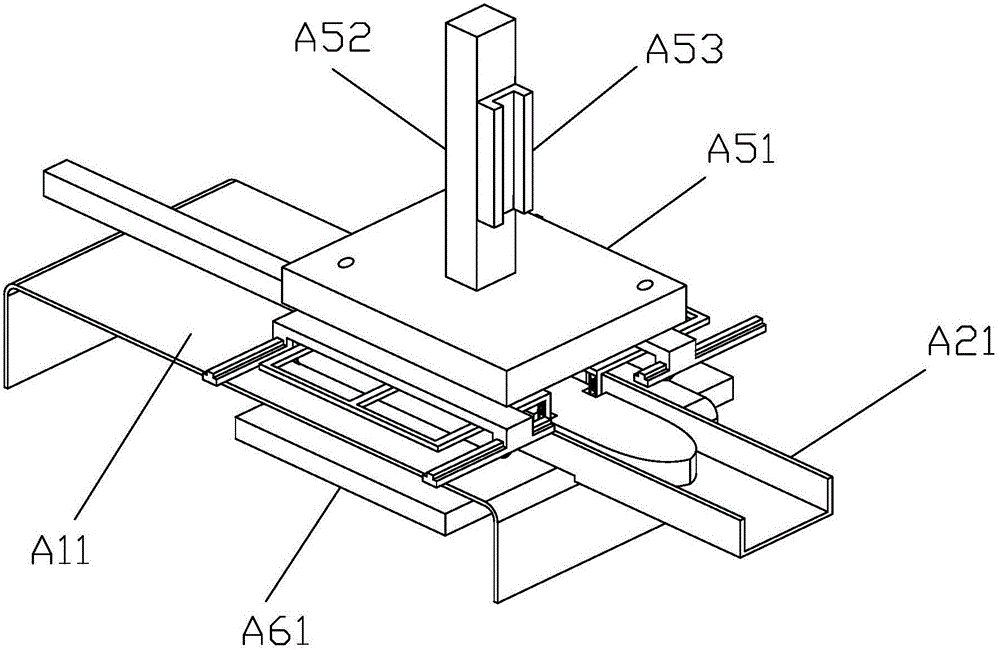

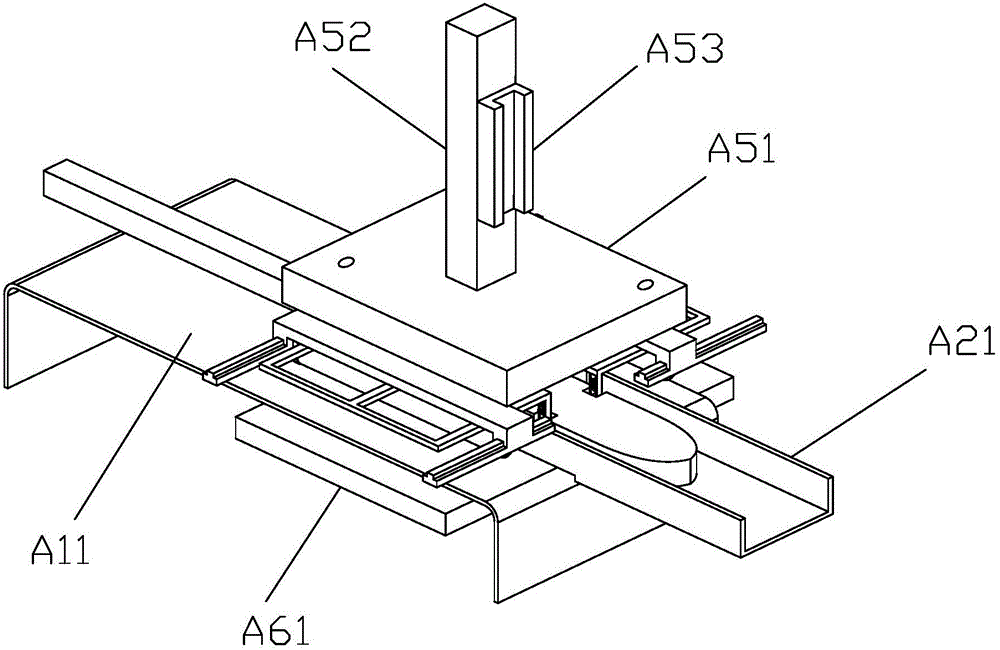

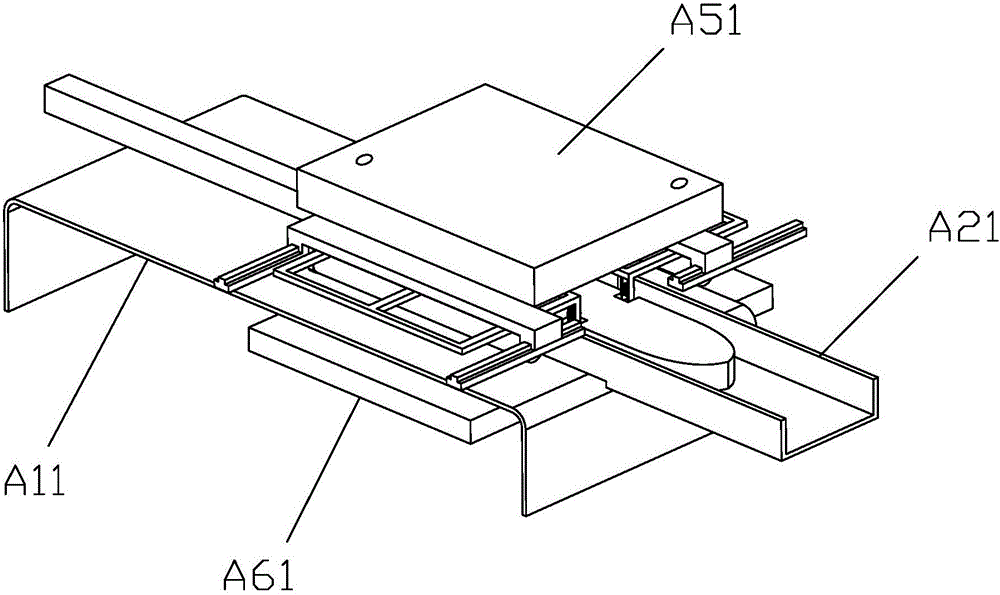

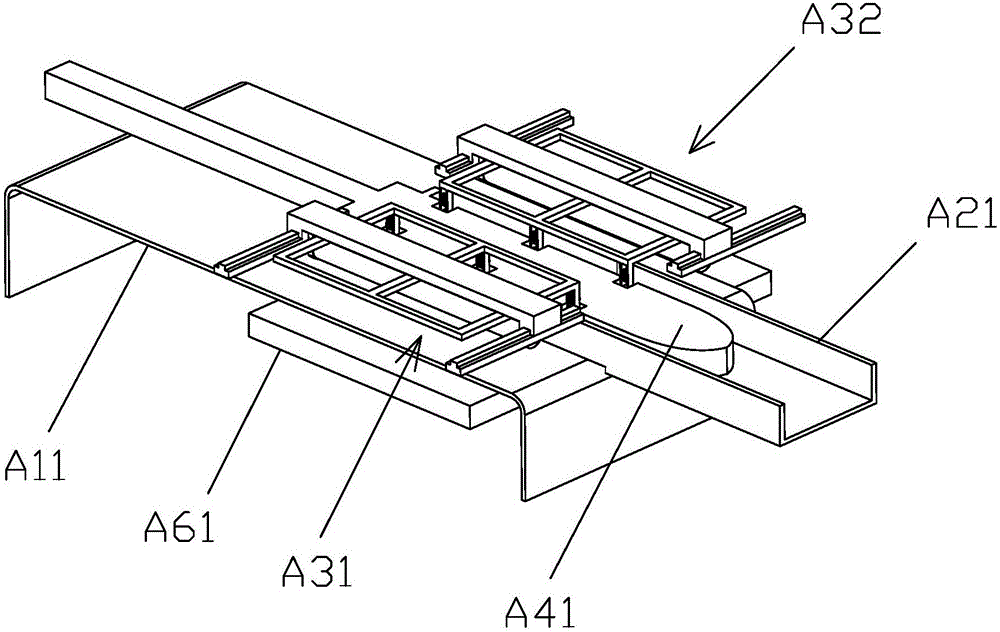

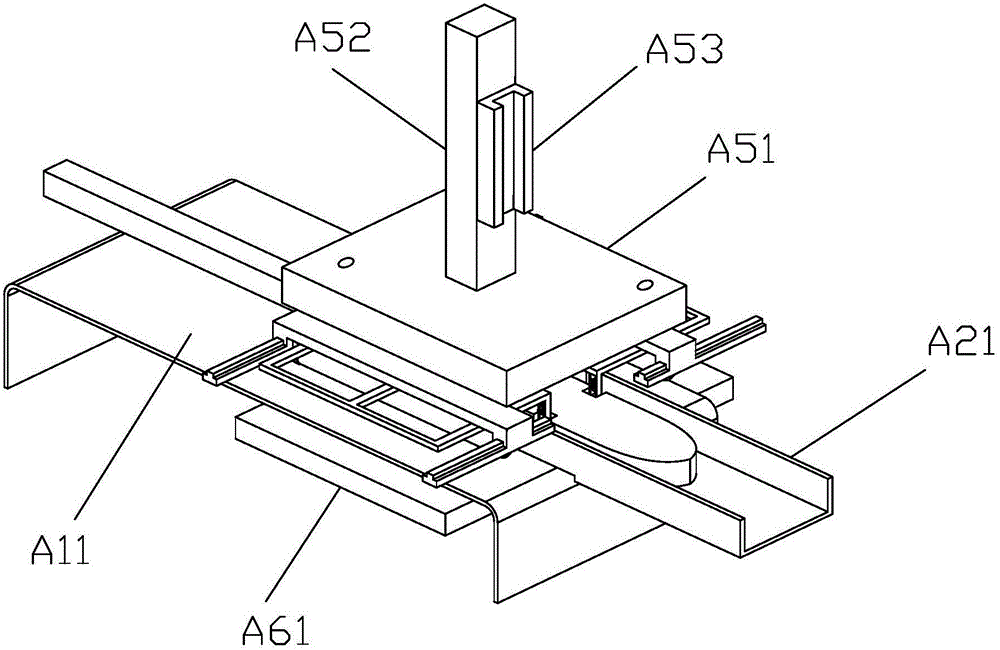

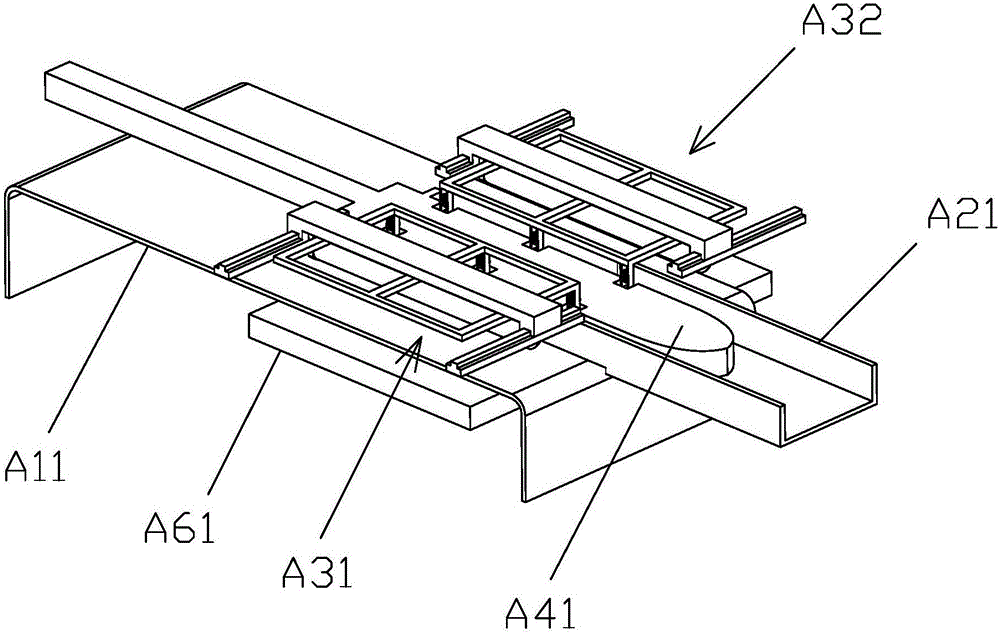

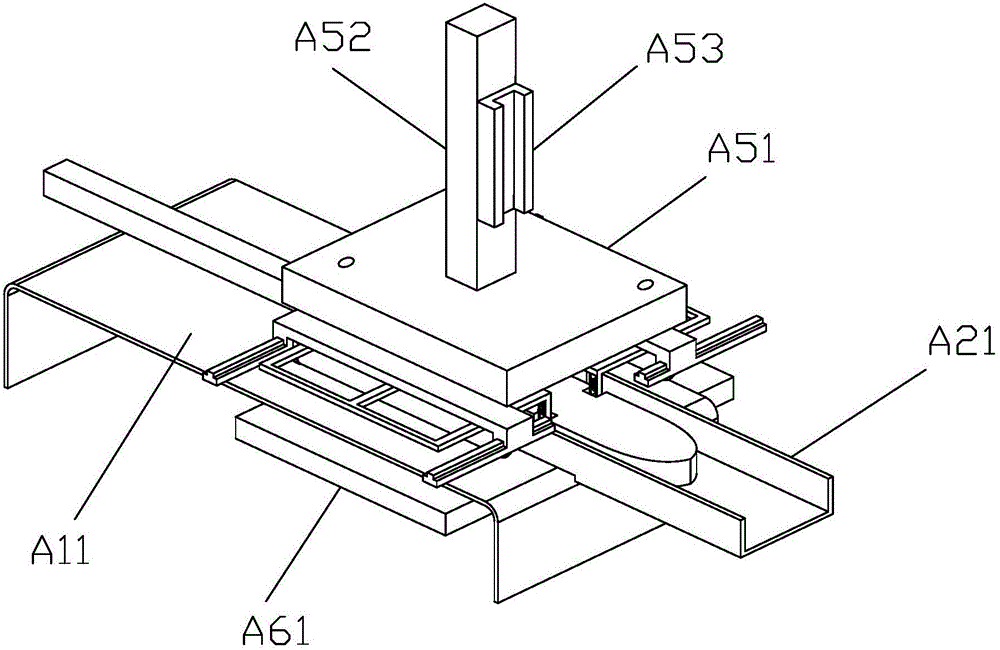

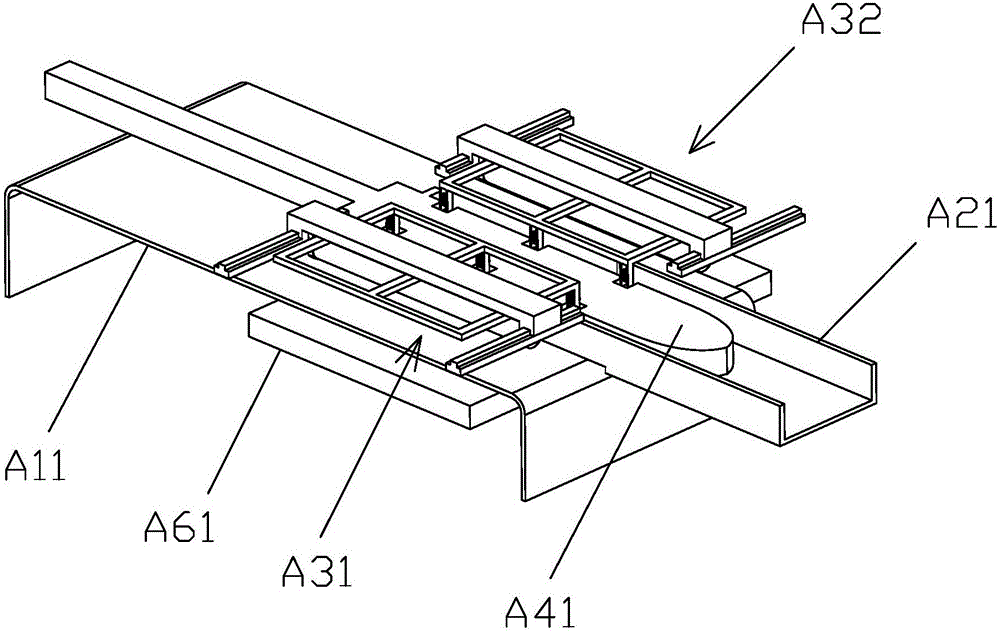

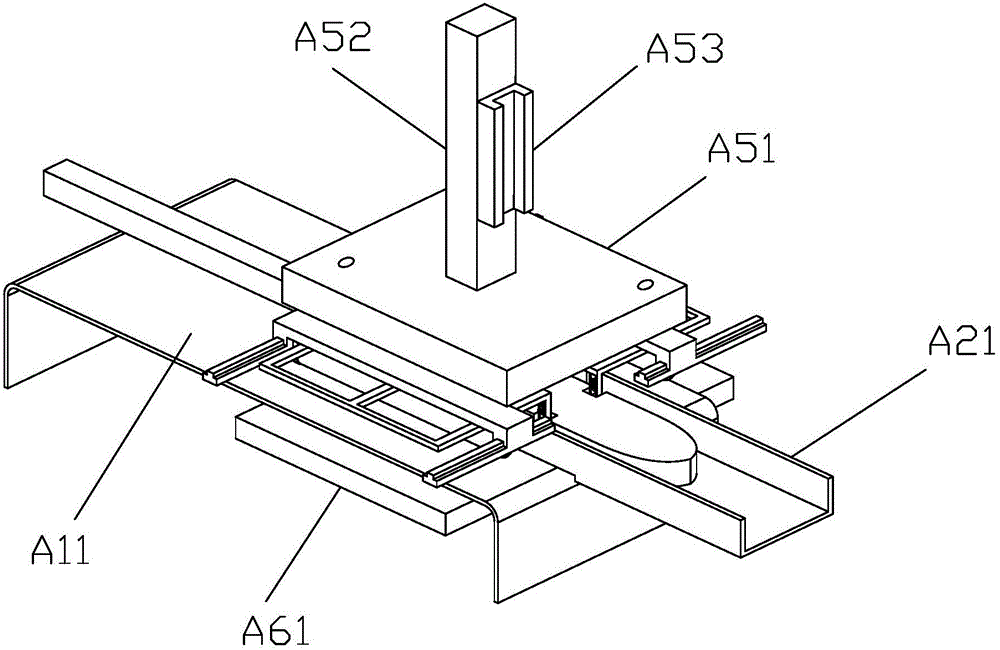

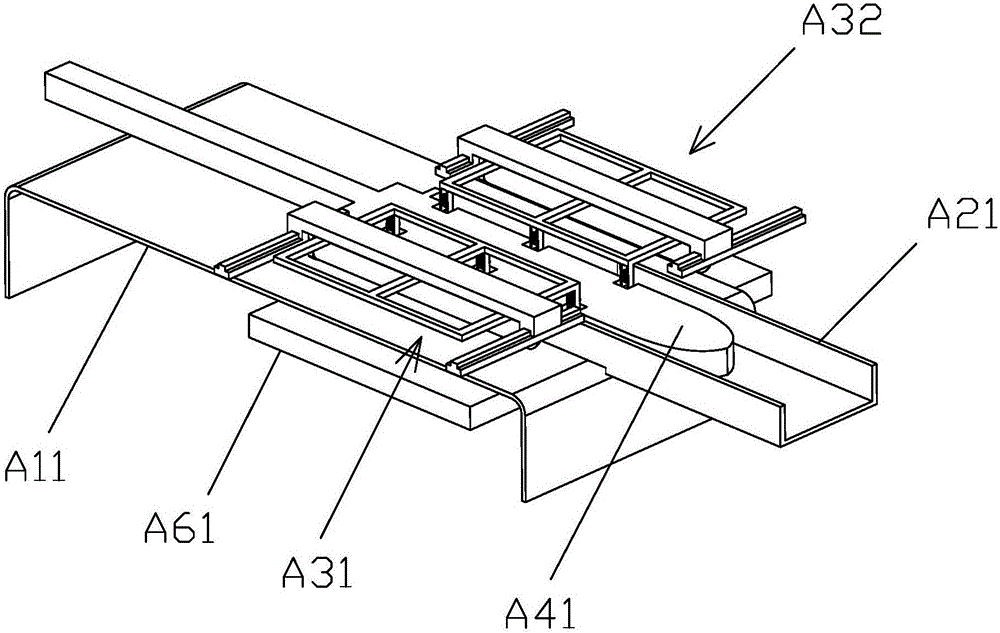

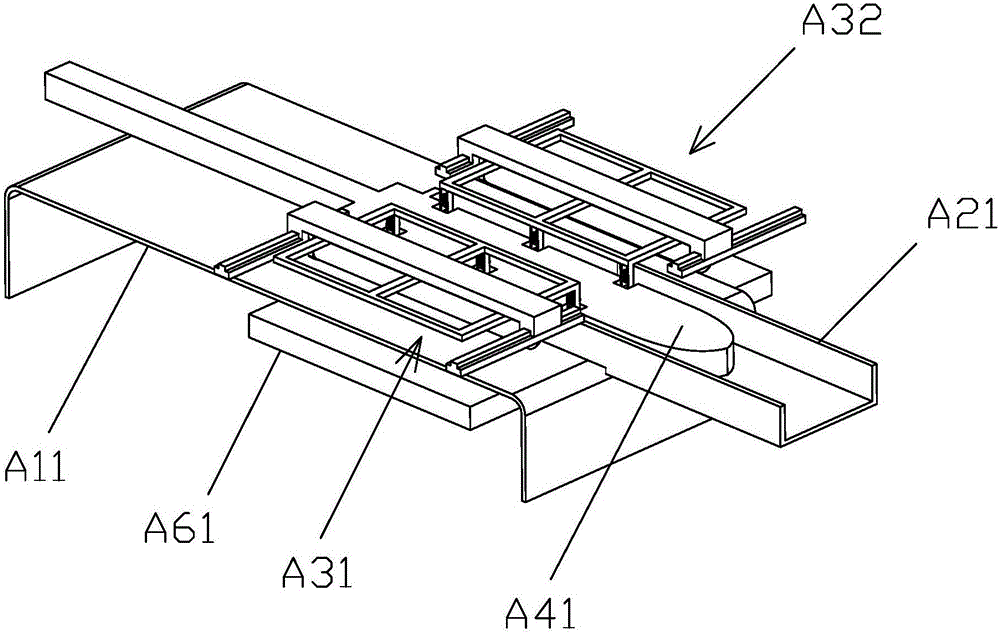

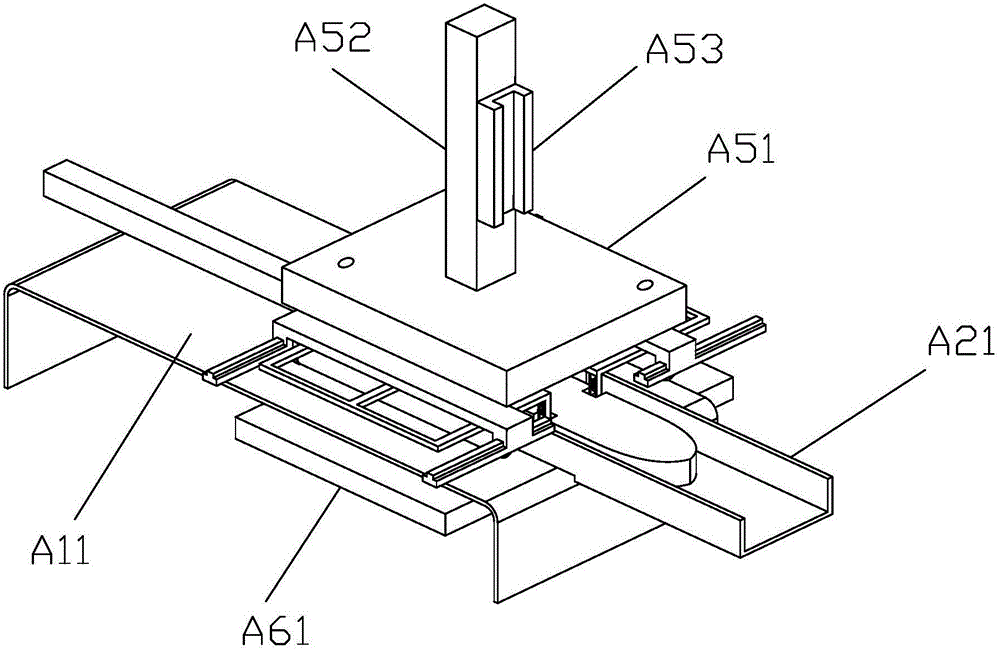

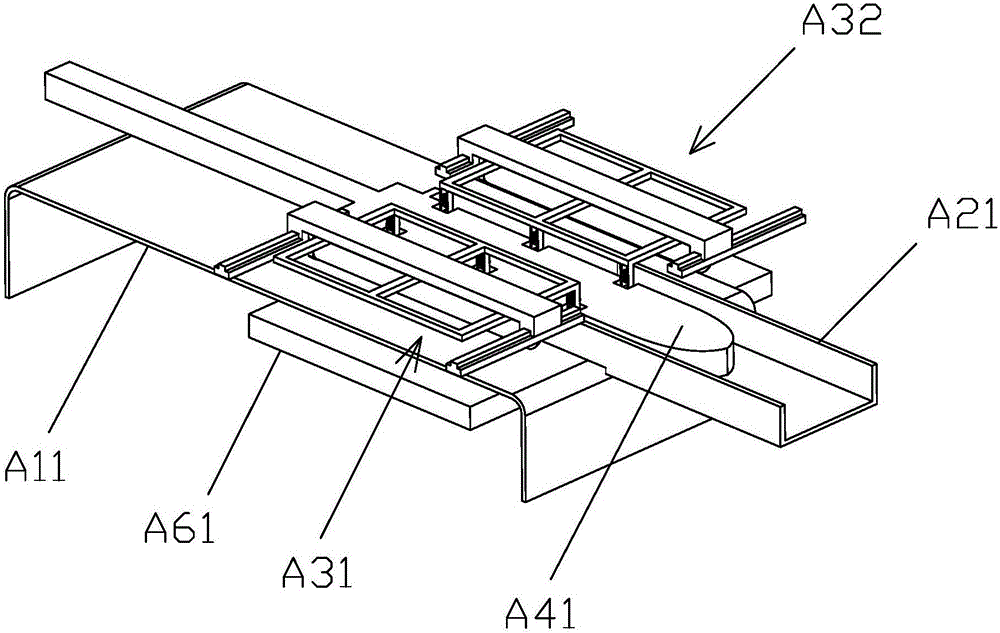

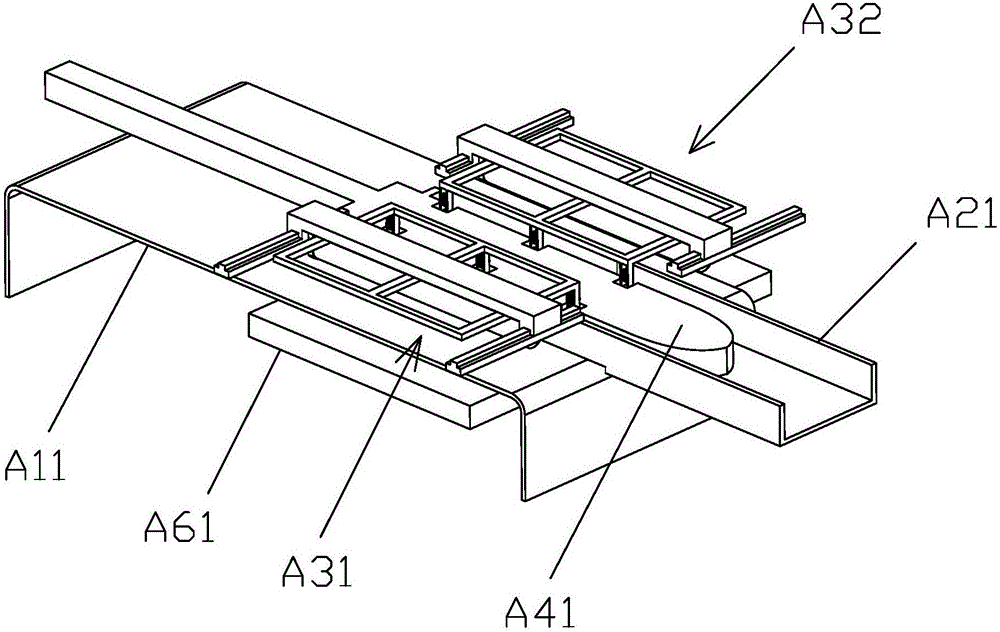

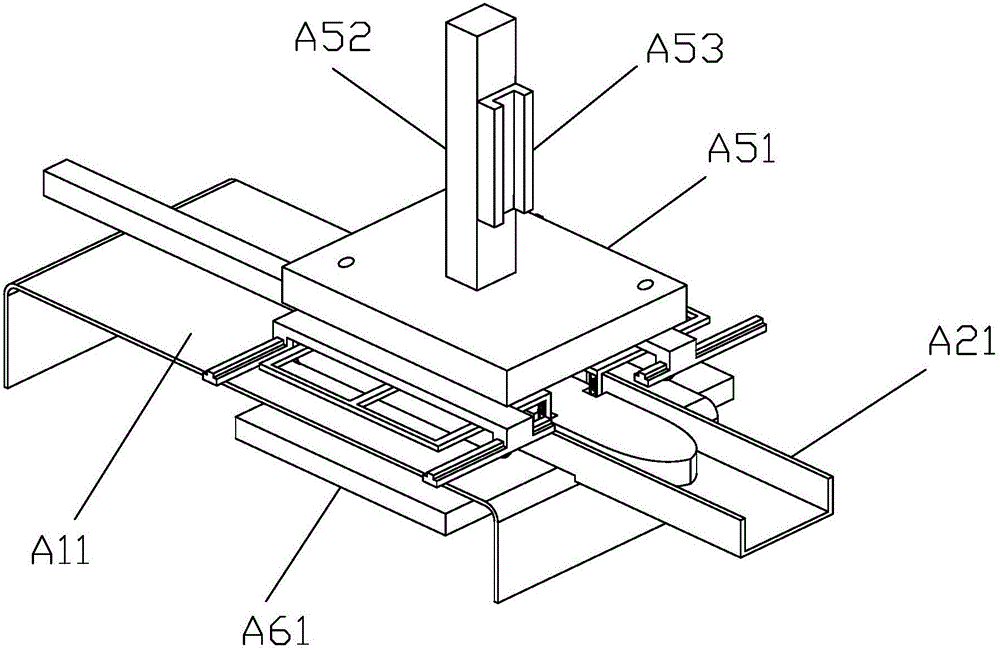

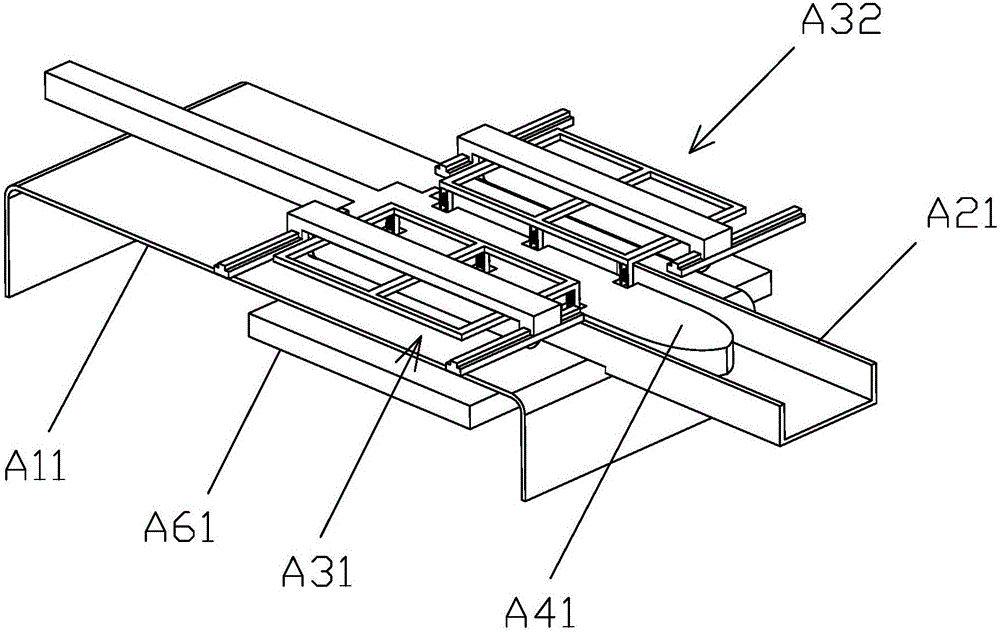

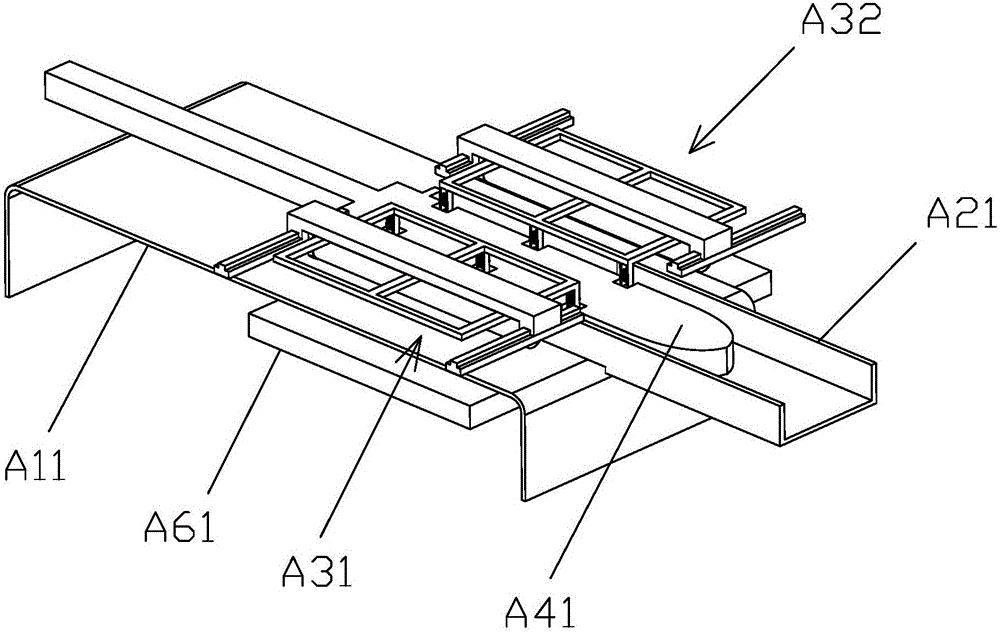

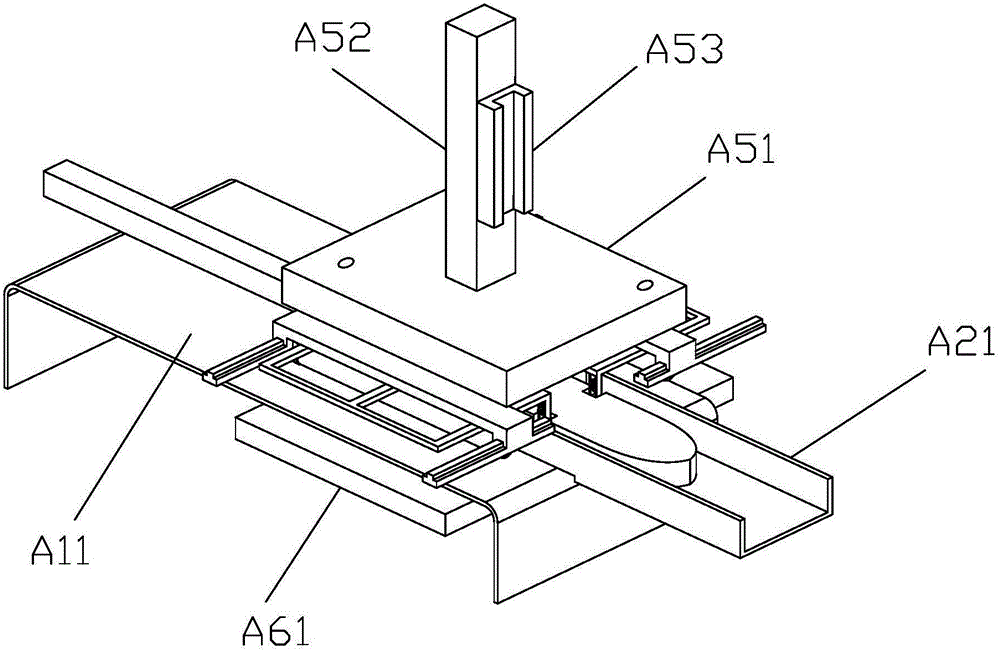

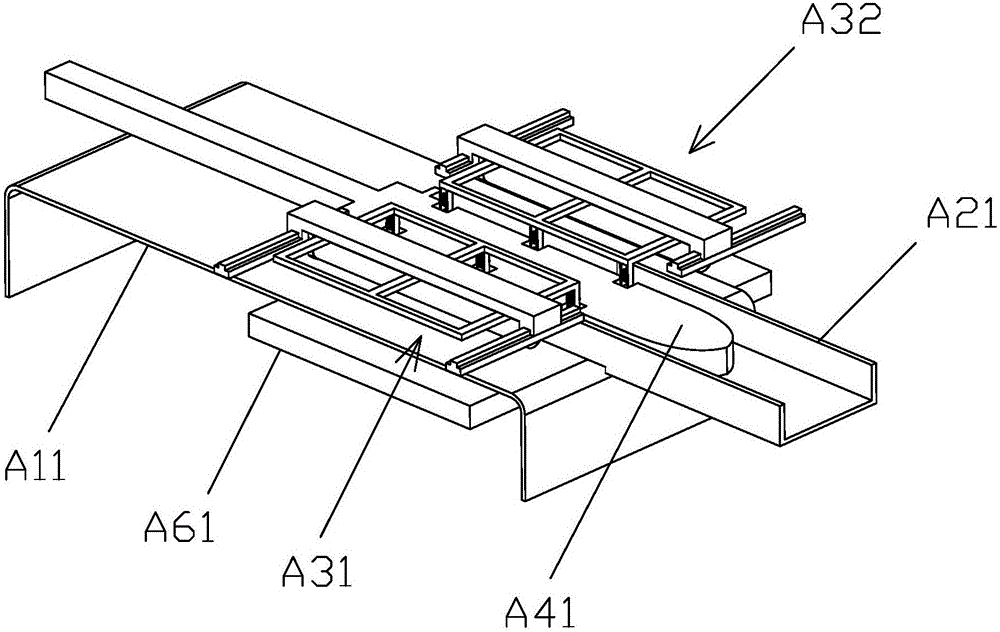

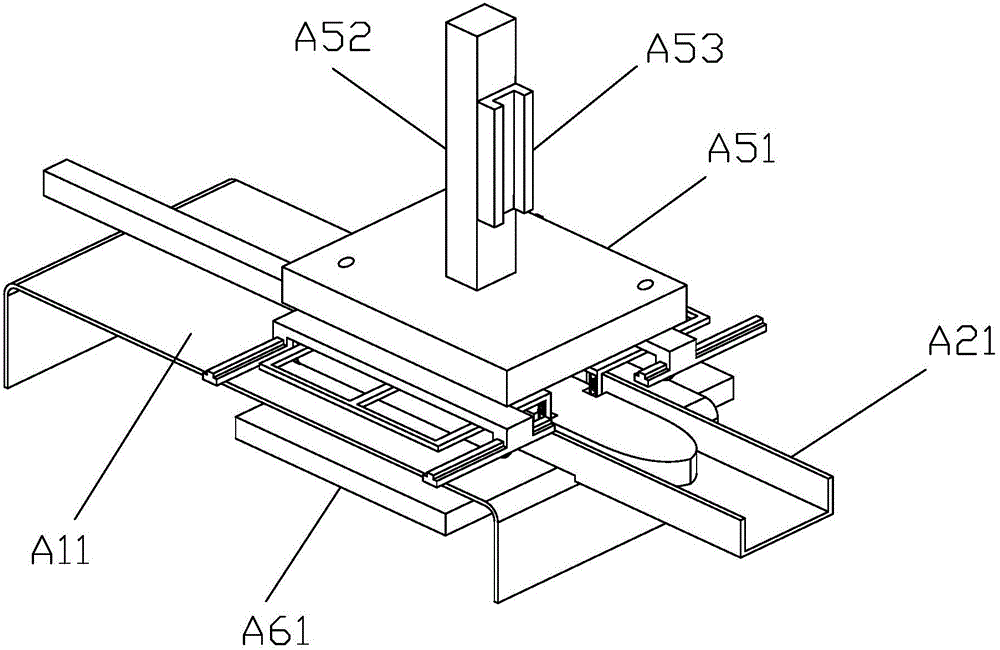

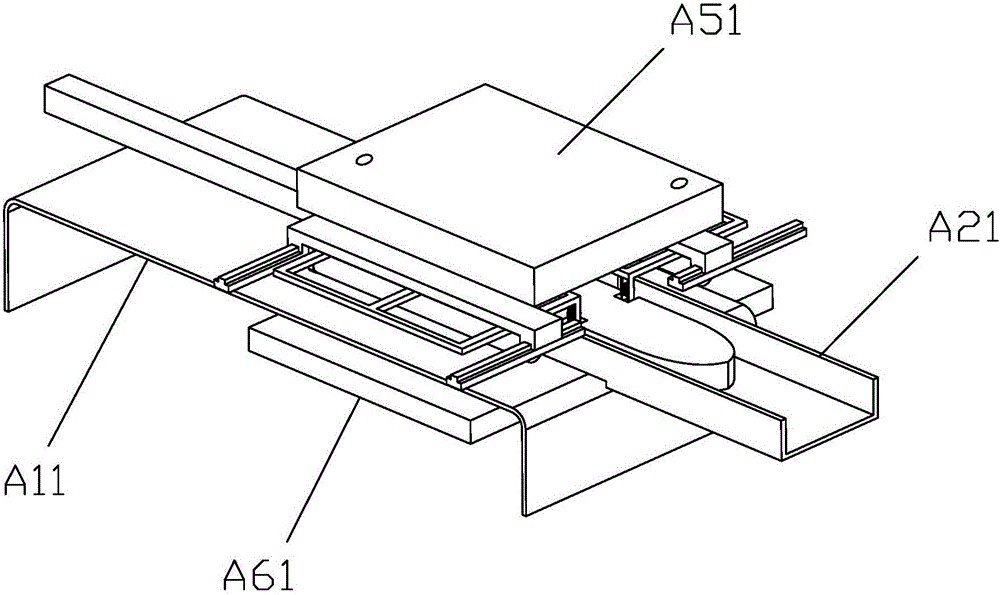

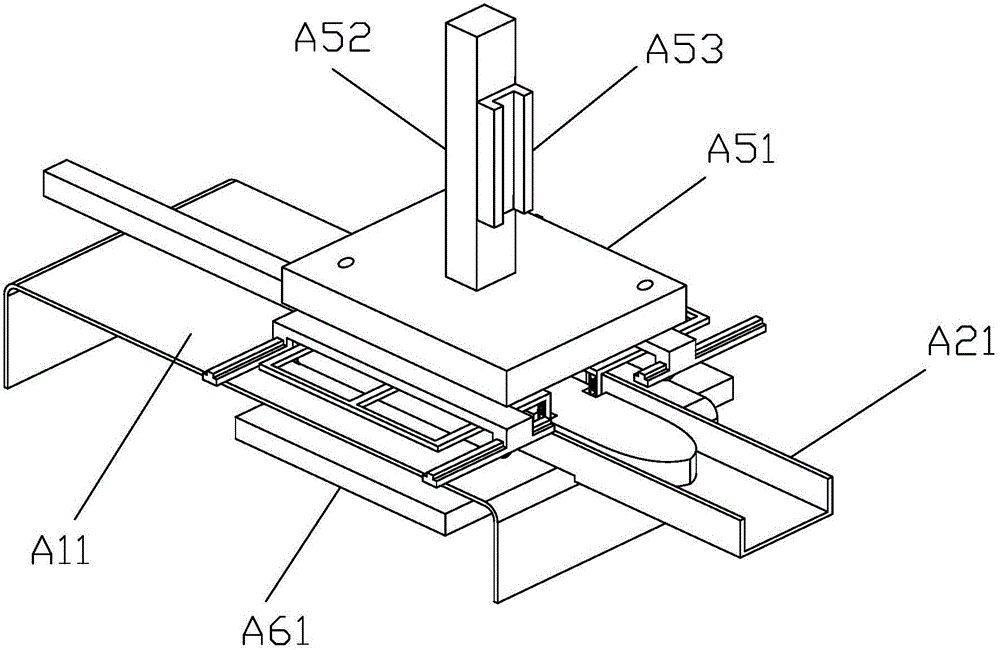

The invention relates to a method for quickly flattening bamboo shells. The method comprises the following steps of pushing the bamboo shells from the inside of a bamboo shell feeding chute to the inside of a bamboo shell conveying belt, and starting the bamboo shell conveying belt to convey the bamboo shells; after winding end faces at the head ends of the bamboo shells are abutted against stopping blocks, stopping conveying of the bamboo shell conveying belt; driving first and second flattening units to move towards the direction away from a bamboo shell guiding plate for completely spreading wound end parts of the bamboo shells by a driving mechanism C; after the bamboo shells are completely spread, driving an ironing plate to downwards move for ironing and shaping the bamboo shells by a driving mechanism D; after the ironing and shaping of the bamboo shells are ended, driving the ironing plate to upwards move and restore to an initial state by the driving mechanism D, driving the bamboo shell guiding plate to restore to a working position by a driving mechanism B; driving the first and second flattening unit to restore to preparation positions by the driving mechanism C; and then driving the bamboo shell conveying belt to operate for unloading the ironed and shaped bamboo shells for preparing the feeding of next bamboo shells by a driving mechanism A. According to the technical scheme, the bamboo shells can be effectively flattened, and reliable support is provided for processing and utilization of the bamboo shells.

Owner:王寿南

Operation method for pretreating phyllostachys pubescens shells through airing rack and flattening device

InactiveCN106042101AEffective flatteningReliable supportWood treatment detailsCane mechanical workingEngineeringPre treatment

The invention relates to an operation method for pretreating bamboo shells of bamboo bamboo by using a drying rack and a flattening device. The cleaned bamboo shells are naturally dried on the drying racks so that the moisture content of the bamboo shells is reduced to 18-20. %, and then sent to the flattening device to flatten it, the flattened bamboo shells are stacked into bundles, and then pressed; the feeding end of the bamboo shell conveyor belt is provided with a device for pushing bamboo to the bamboo shell conveyor belt. The bamboo shell feeding chute of the shell, the groove length direction of the bamboo shell feeding chute is consistent with the conveying direction of the bamboo shell conveyor belt, and the inner surface of the bottom of the bamboo shell feeding chute is arranged flush with the conveying surface of the upper layer of the bamboo shell conveyor belt , the two groove walls of the bamboo shell feeding trough are extended to the inside of the bamboo shell conveyor belt to set a guiding extension section, and the top of the bamboo shell conveyor belt is provided with a flattening mechanism for flattening the bamboo shells and pressing the flattened bamboo shells A stereotyped ironing and pressing mechanism; the above-mentioned technical scheme can effectively flatten the bamboo shells and provide reliable support for the processing and utilization of the bamboo shells.

Owner:王寿南

Equipment for preprocessing bamboo sheath waste through combined use of airing frame, dehairing device and flattening device

InactiveCN106078956AEffective flatteningReliable supportWood treatment detailsCane mechanical workingCombined useEngineering

The invention relates to equipment for preprocessing bamboo sheath waste through combined use of an airing frame, a dehairing device and a flattening device. The equipment comprises the dehairing device, a soaking tank, a cooking device, a washing tank, the airing frame, the flattening device and a pressing and trimming machine, wherein a bamboo casing guiding plate is arranged on a bamboo casing conveyor belt; the bamboo casing guiding plate is arranged above the bamboo casing conveyor belt, the spacing between the bamboo casing guiding plate and the bamboo casing conveyor belt is d1, the thickness of each bamboo casing is d2, and the d1 is greater than the d2; the bamboo casing guiding plate is arranged in a bamboo casing feeding tank in the same direction in which the bamboo casing guiding plate is arranged; the width of the bamboo casing guiding plate is less than that of the bamboo casing feeding tank; vacant parts are separately formed in two side parts of the bamboo casing guiding plate towards the body of the bamboo casing guiding plate; the bamboo casing guiding plate is connected with a driving mechanism B; the bamboo casing guiding plate is mounted on a machine frame A in a sliding manner in the length direction of the bamboo casing feeding tank, and is adjusted by the driving mechanism B to move in the length direction of the bamboo casing feeding tank. According to the technical scheme of the equipment disclosed by the invention, flattening the bamboo casings can be effectively performed, and reliable support is provided for the processing and the utilization of the bamboo casings.

Owner:王寿南

System for pre-treating phyllostachys pubescens bamboo shells through burr removing device and flatly-spreading device

InactiveCN105835178AEffective flatteningReliable supportWood treatment detailsCane mechanical workingFuel tankEngineering

The invention relates to a system for pre-treating phyllostachys pubescens bamboo shells through a burr removing device and a flatly-spreading device. The system comprises the burr removing device, a soaking groove, a steaming device, a rinsing bath, an airing support, the flatly-spreading device and a pressing and neatening machine which are sequentially arranged; the burr removing device is used for removing burrs on the outer surfaces of the bamboo shells; the soaking groove is used for soaking the bamboo shells obtained after burr removal; the steaming device is used for steaming the soaked bamboo shells; the rinsing bath is used for rinsing the steamed bamboo shells; the airing support is used for airing the rinsed bamboo shells so as to reduce the water content; the flatly-spreading device is used for flatly spreading the aired bamboo shells; and the pressing and neatening machine is used for stacking, pressing and neatening the flatly-spread bamboo shells. A burning and pressing plate is internally provided with a cavity used for containing heat conduction oil, and a circulation oil way is formed by the cavity by means of an oil conduction pipe, a conveying pump and an oil storage tank; and an electrical heating assembly is arranged in the oil storage tank, and a separating plate is arranged in the cavity and separates the cavity into a circuitous runner allowing the heat conduction oil to flow therein. According to the above technical scheme, the bamboo shells can be effectively spread flatly, and reliable supports are provided for machining and using of the bamboo shells.

Owner:王寿南

Treatment method for pretreating moso bamboo shells by means of steaming device and flattening device

InactiveCN105835159AEffective flatteningReliable supportWood treatment detailsCane mechanical workingHair removalFuel tank

The invention relates to a treatment method for pretreating moso bamboo shells by means of a steaming device and a flattening device. The treatment method comprises the steps that bamboo shells obtained after hair removal are dumped into a soaking tank to be soaked for 0.5 h to 2.5 h, and the bamboo shells fully absorb water; and the soaked bamboo shells are put into the steaming device to be steamed for 5 min to 8 min, and the steamed bamboo shells are put into a washing tank to be washed. The interior of a hot pressing plate is arranged to be in the shape of a cavity used for containing heat conduction oil. A circulating oil path is formed by the cavity via oil conduction pipes, a conveying pump and an oil storage box. An electric heating assembly is arranged in the oil storage box. Partition plates are arranged in the cavity and divide the cavity into a circuitous runner allowing the heat conduction oil to flow. According to the technical scheme, the bamboo shells can be effectively flattened, and reliable support is provided for machining and utilizing of the bamboo shells.

Owner:王寿南

System for pretreating moso bamboo shells by means of steaming device and flattening device

InactiveCN105835152AFlat and reliableImprove processing efficiencyWood treatment detailsCane mechanical workingFuel tankEngineering

The invention relates to a system for pretreating moso bamboo shells by means of a steaming device and a flattening device. The system comprises a hair removal device, a soaking tank, the steaming device, a washing tank, an airing rack, the flattening device and a pressing machine. The interior of a hot pressing plate is arranged to be in the shape of a cavity used for containing heat conduction oil. A circulating oil path is formed by the cavity via oil conduction pipes, a conveying pump and an oil storage box. An electric heating assembly is arranged in the oil storage box. Partition plates are arranged in the cavity and divide the cavity into a circuitous runner allowing the heat conduction oil to flow. According to the technical scheme, the bamboo shells can be effectively flattened, and reliable support is provided for machining and utilizing of the bamboo shells.

Owner:王寿南

Novel technology using airing shelf, dehairing device and flattening device together in pretreatment of culm and sheath wastes

InactiveCN105835170AFlat and reliableImprove processing efficiencyWood treatment detailsCane mechanical workingWater contentPre treatment

The invention relates to a novel technology using an airing shelf, a dehairing device and a flattening device together in the pretreatment of culm and sheath wastes. The novel technology comprises the following steps: pouring dehaired bamboo sheaths into a soaking trough and soaking for 0.5 to 2.5h until the bamboo sheaths fully absorb water; stewing the soaked bamboo sheaths for 5-8min, placing the stewed bamboo sheaths into a water washing trough and washing the bamboo sheaths; naturally airing the washed bamboo sheaths on the airing shelf until the water content of the bamboo sheaths is reduced to about 18-20%; then conveying the bamboo sheaths to the flattening device, flattening the bamboo sheaths, and stacking the bamboo sheaths flattened into bundles; and then, pressing the bundles. The width of a bamboo sheath guide plate is smaller than the trough width of a bamboo sheath conveying trough, the two sides of the bamboo sheath guide plate are separately provided with notch parts towards the main body of the bamboo sheath guide plate, the bamboo sheath guide plate is connected with a driving mechanism B, the bamboo sheath guide plate is mounted on a rack A in a sliding manner in the trough length direction of the bamboo sheath conveying trough, and the driving mechanism B regulates the bamboo sheath guide plate to move in the trough length direction of the bamboo sheath conveying trough. The technical scheme can effectively flatten the bamboo sheaths and provide reliable support for the processing and utilization of the bamboo sheaths.

Owner:王寿南

Culm sheath pretreating system comprising steaming device, airing frame and flattening device

InactiveCN106003288AEffective flatteningReliable supportWood treatment detailsCane mechanical workingHeat conductingFuel tank

The invention relates to a culm sheath pretreating system comprising a steaming device, an airing frame and a flattening device. The system comprises a shedding device, a soaking tank, the steaming device, a water washing tank, the airing frame, the flattening device and a press trimming machine, wherein a cavity for accommodating heat conducting oil is formed inside a hot pressing plate and forms a circulating oil way by the aid of an oil conducting pipe, a delivery pump and an oil storage box, an electric heating assembly is arranged in the oil storage box, and separating plates are arranged in the cavity and divide the cavity into a sinuous flow channel allowing flowing of the heat conducting oil. With the adoption of the technical scheme, bamboo shells can be flattened effectively, and reliable support is provided for processing and utilization of the bamboo shells.

Owner:王寿南

System for pretreating bamboo shells by means of combination of hair removal device and flattening device

InactiveCN105835158AEffective flatteningReliable supportWood treatment detailsCane mechanical workingEngineeringPre treatment

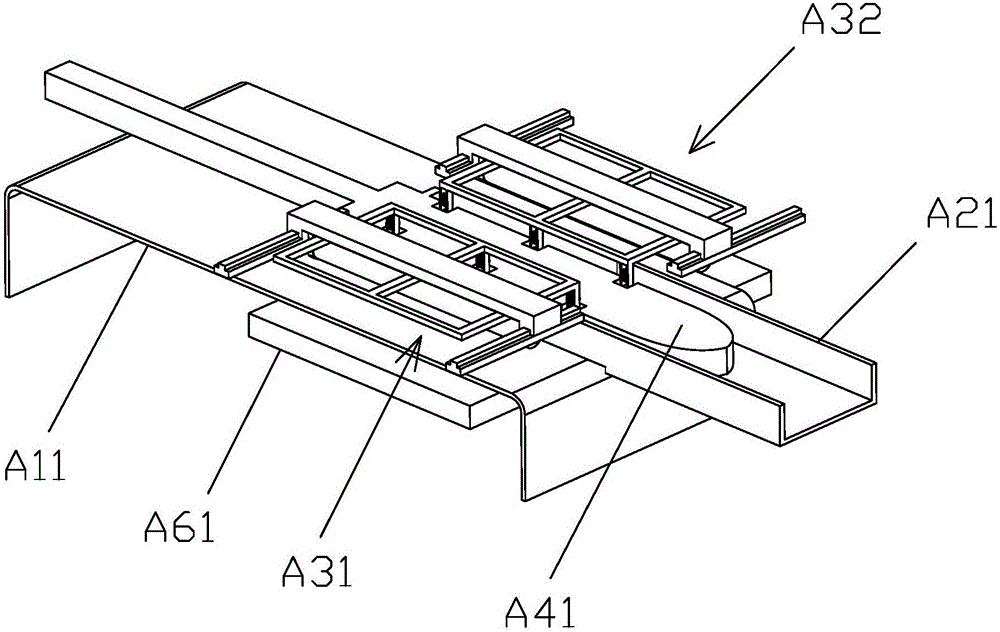

The invention relates to a system for pretreating bamboo shells by combining a depilation device and a flattening device, comprising a depilation device arranged in sequence to remove hairs on the outer surface of the bamboo shells, a soaking tank for soaking the depilated bamboo shells, and a soaking tank for soaking the bamboo shells after soaking. The cooking device for cooking the bamboo shells, the washing tank for cleaning the boiled bamboo shells, the drying rack for drying the cleaned bamboo shells to reduce the moisture content, and the flattening of the dried bamboo shells Flattening device, a compacting machine for stacking and pressing the flattened bamboo shells; the first and second flattening units are in two states, one of which is: when the bamboo shell guide plate is in the working position, the first and second wires Wheel is positioned at the preparatory position in the vacant part, and its two is: drive mechanism C regulates the first and second guide wheel to move away from the bamboo shell guide plate one side and the bamboo shell is spread out and flattened. The above-mentioned technical scheme can effectively flatten the bamboo shell, and provide reliable support for the processing and utilization of the bamboo shell.

Owner:王寿南

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com