Method of manufacturing rotor of electric motor and electric motor

A manufacturing method and motor technology, which is applied in the field of motors, can solve the problems of peeling, lower mechanical strength, and higher manufacturing costs, and achieve the effects of preventing peeling, improving reliability, and improving manufacturing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

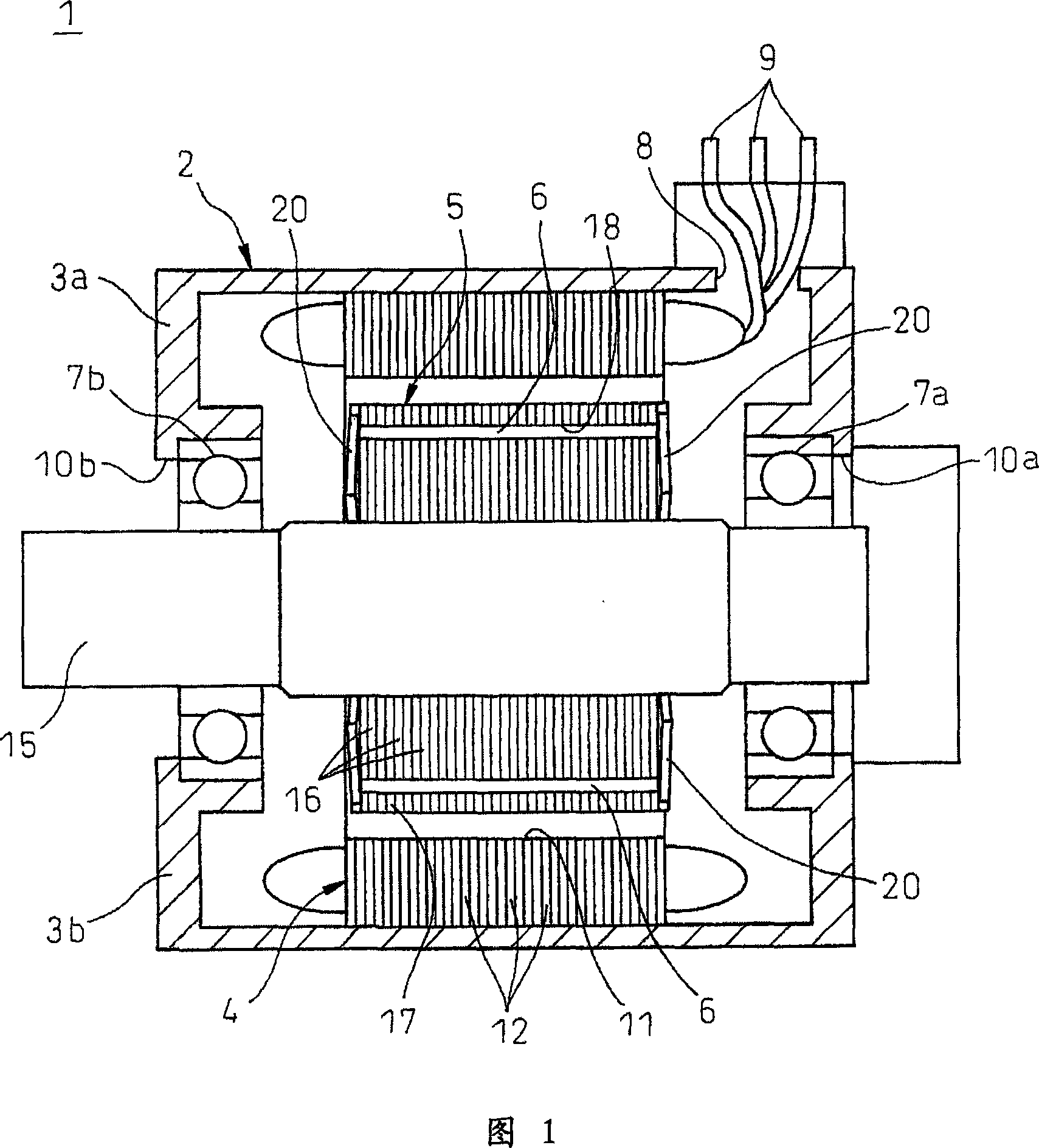

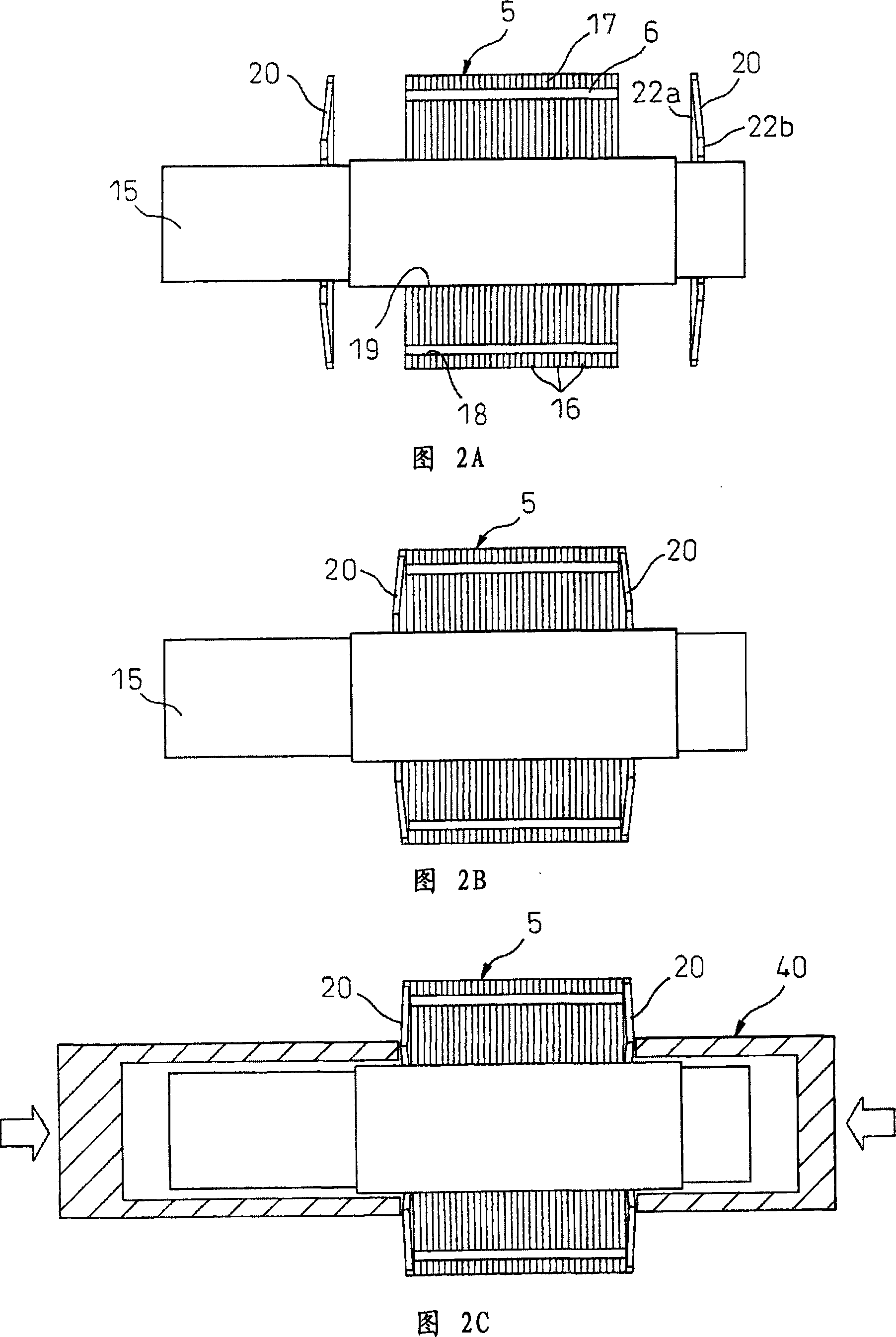

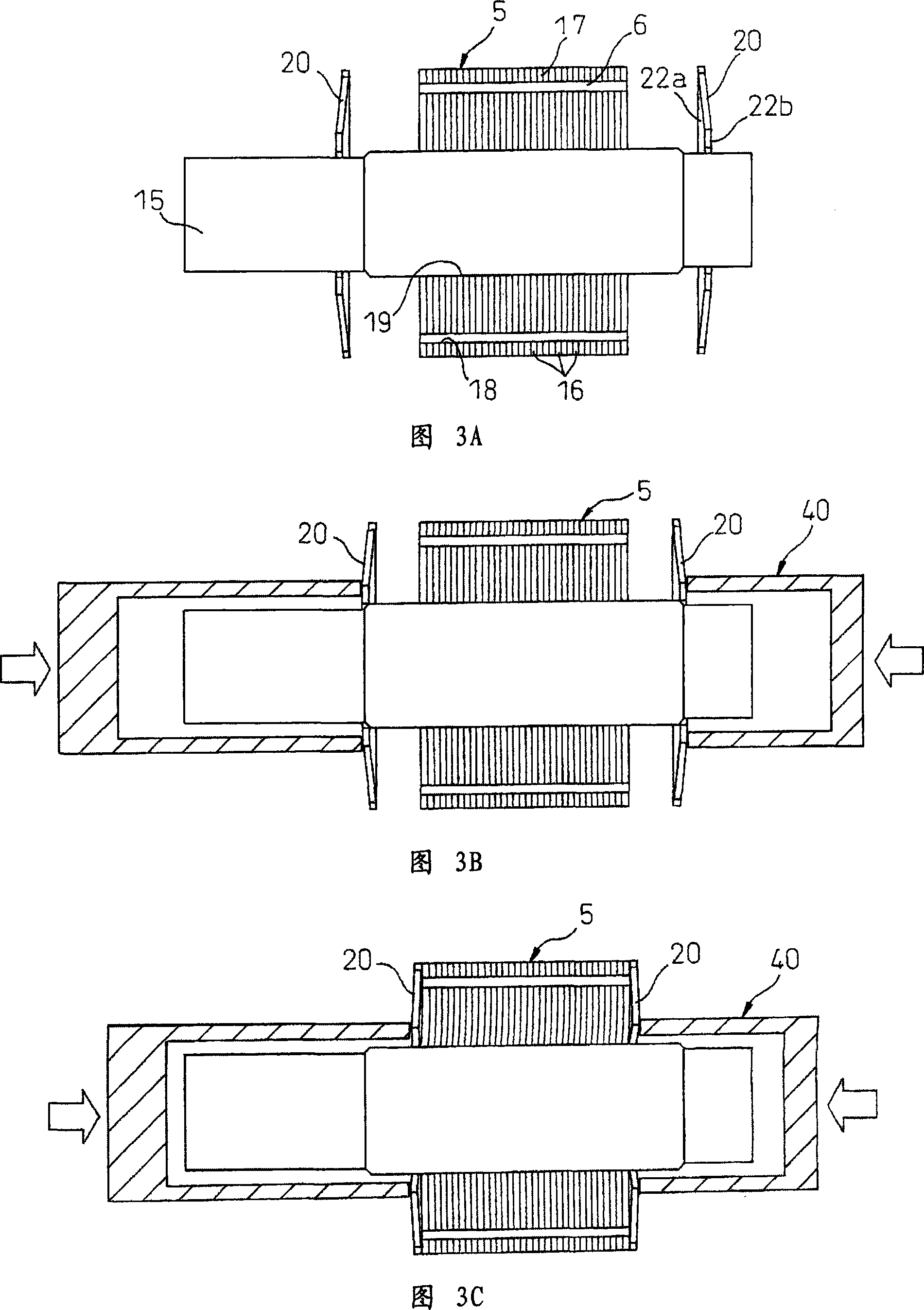

[0037] Specific examples of embodiments of the present invention will be described in detail below using the drawings. FIG. 1 shows an embodiment of a motor according to the present invention. The motor 1 of the present embodiment includes: a cylindrical casing 2; an outer stator 4 provided annularly along the inner peripheral surface of the casing 2; and an inner rotor (motor rotor) rotatably arranged inside the outer stator 4. 5; a plurality of magnets 6 embedded at equal intervals in the circumferential direction of the inner rotor 5; and a pair of bearings 7a, 7b pivotally supporting the rotating shaft 15 of the inner rotor 5 on both left and right sides.

[0038] The housing 2 is made of a non-magnetic material such as aluminum, and is composed of an upper housing 3a and a lower housing 3b having a split structure. The upper and lower pairs of housings 3a and 3b can be assembled integrally after disposing the inner rotor 5 inside the outer stator 4 . Three electric wire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com