Method of preparing mould core, mould core and mould using the mould core

A manufacturing method and mold core technology, which are applied in manufacturing tools, glass manufacturing equipment, glass molding, etc., can solve the problems of misalignment between geometric center lines and eccentricity in optical lens molding, and achieve the effect of improving manufacturing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

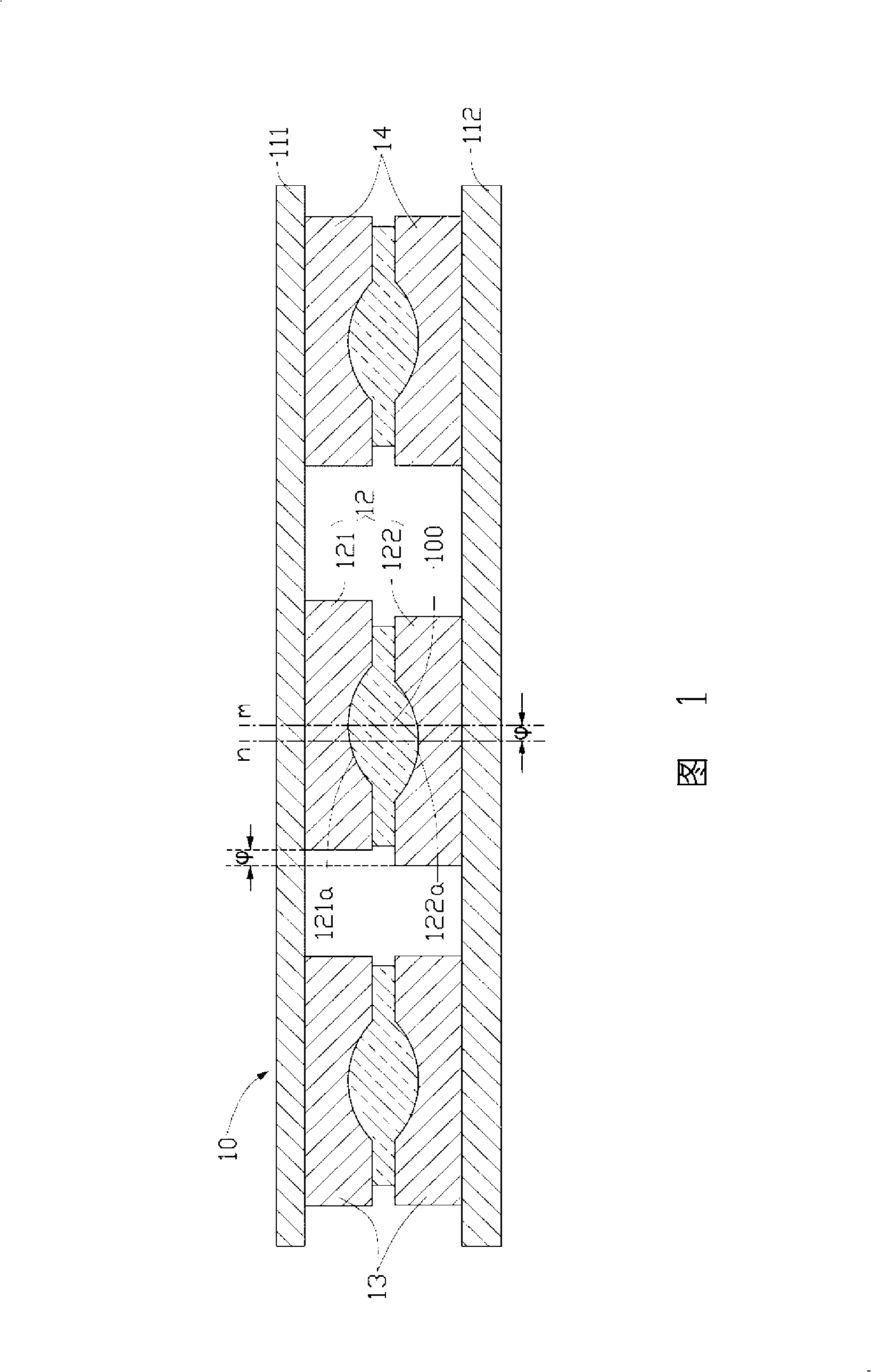

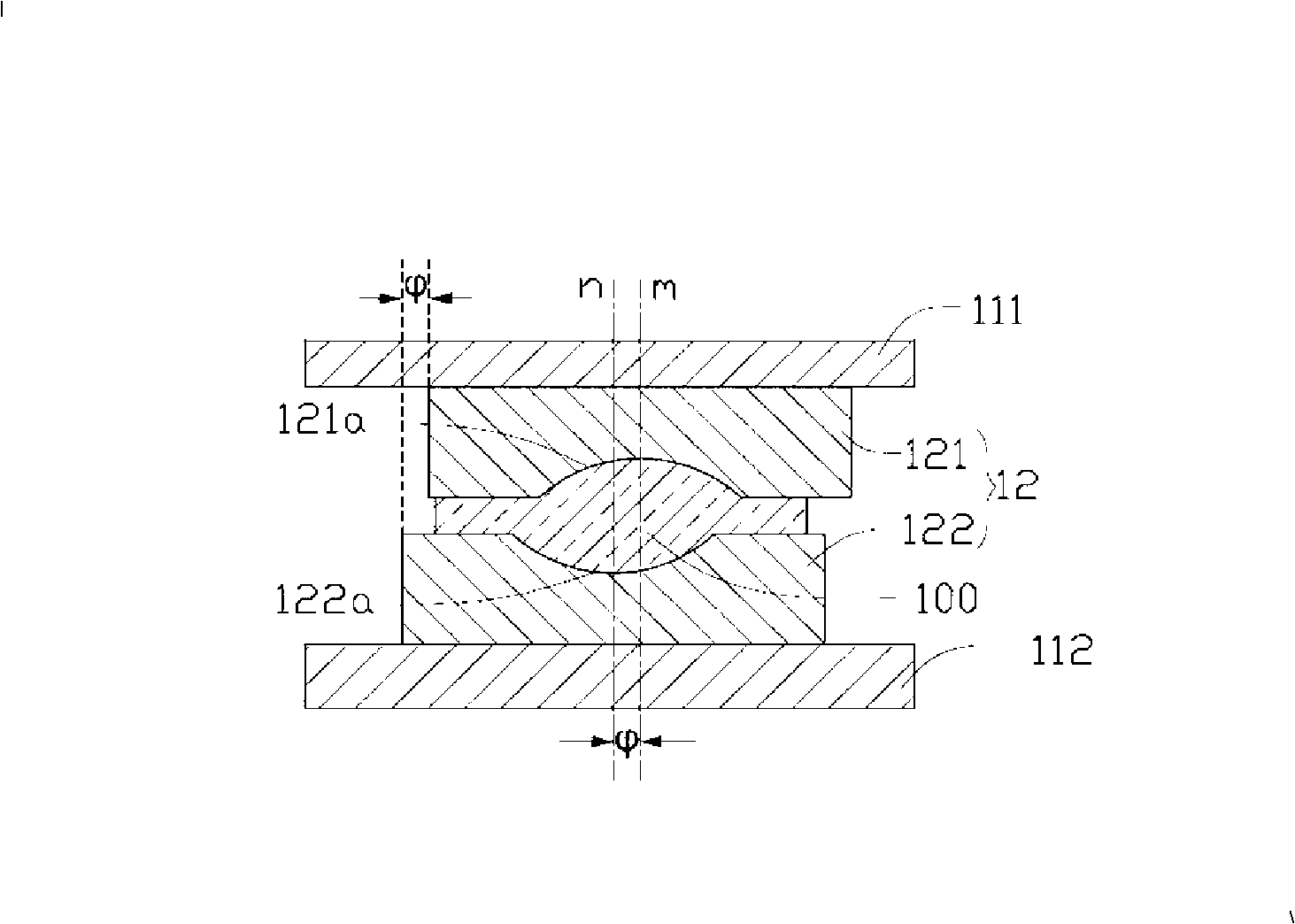

[0025] see figure 2 and image 3 , the mold core manufacturing method provided by the first embodiment of the present invention, which includes the following steps:

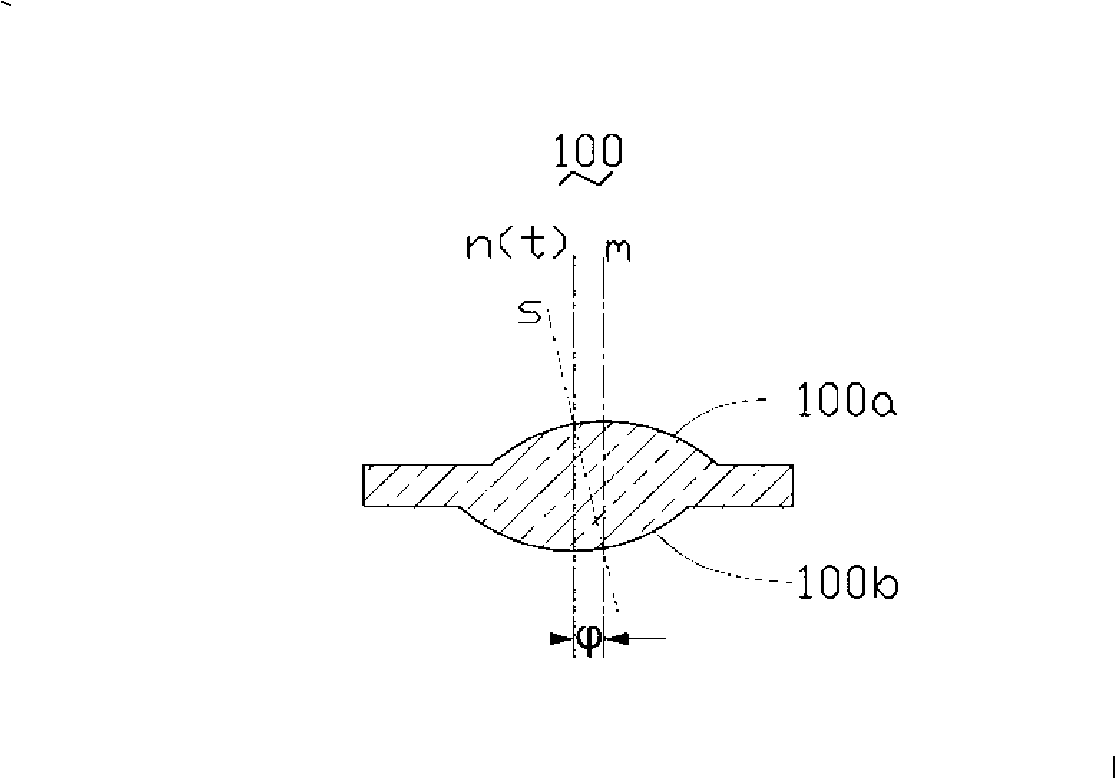

[0026] (1) An eccentric mold core is provided and the deviation of the eccentric mold core is measured. The eccentric mold core is used for molding an optical lens having two opposite first and second curved surfaces.

[0027] The eccentric mold core 12 includes a first eccentric mold piece 121 and a second eccentric mold piece 122, the first eccentric mold piece 121 is installed on the first mold base 111, and the second eccentric mold piece 122 is mounted on the second mold base 112 . The second eccentric die 122 is arranged opposite to the first eccentric die 121, the first eccentric die 121 includes a first molding surface 121a for molding the first curved surface 100a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com