Pipe fitting welding tool and method capable of guaranteeing butt-joint concentricity

A pipe fitting welding and coaxiality technology, which is applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems affecting the installation of main pipes and the inability to guarantee the dimensional accuracy of pipe fittings, so as to achieve stable product quality, stabilize production quality, and improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments. All equivalent changes and modifications made according to the contents of this specification shall fall within the scope of protection claimed by the application of the present invention.

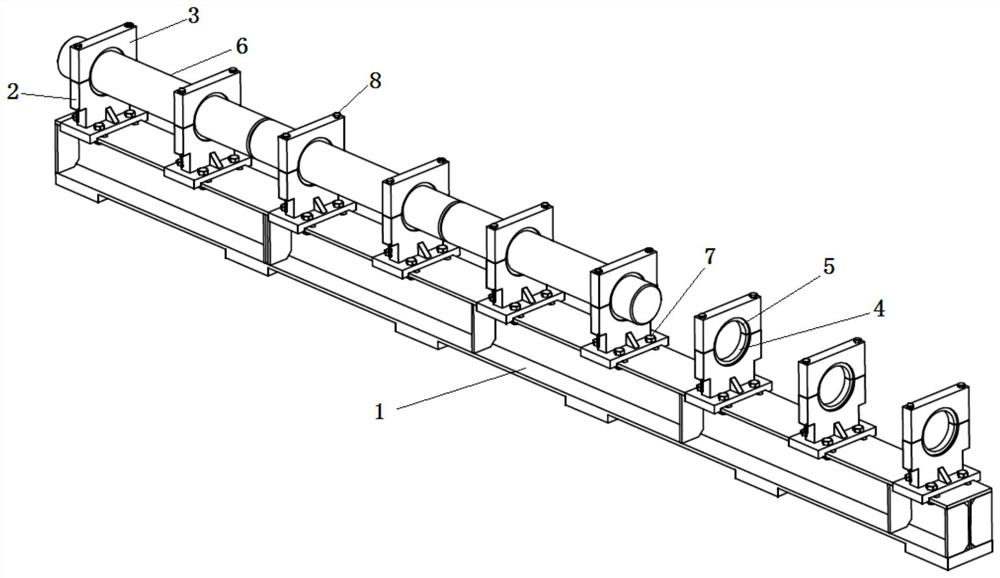

[0044] see figure 1 , the pipe fitting welding tool shown in the figure is used for the assembly and welding of the inner pipe of the stainless steel double-wall pipe for marine low-speed diesel engines. The diameter of the inner pipe is

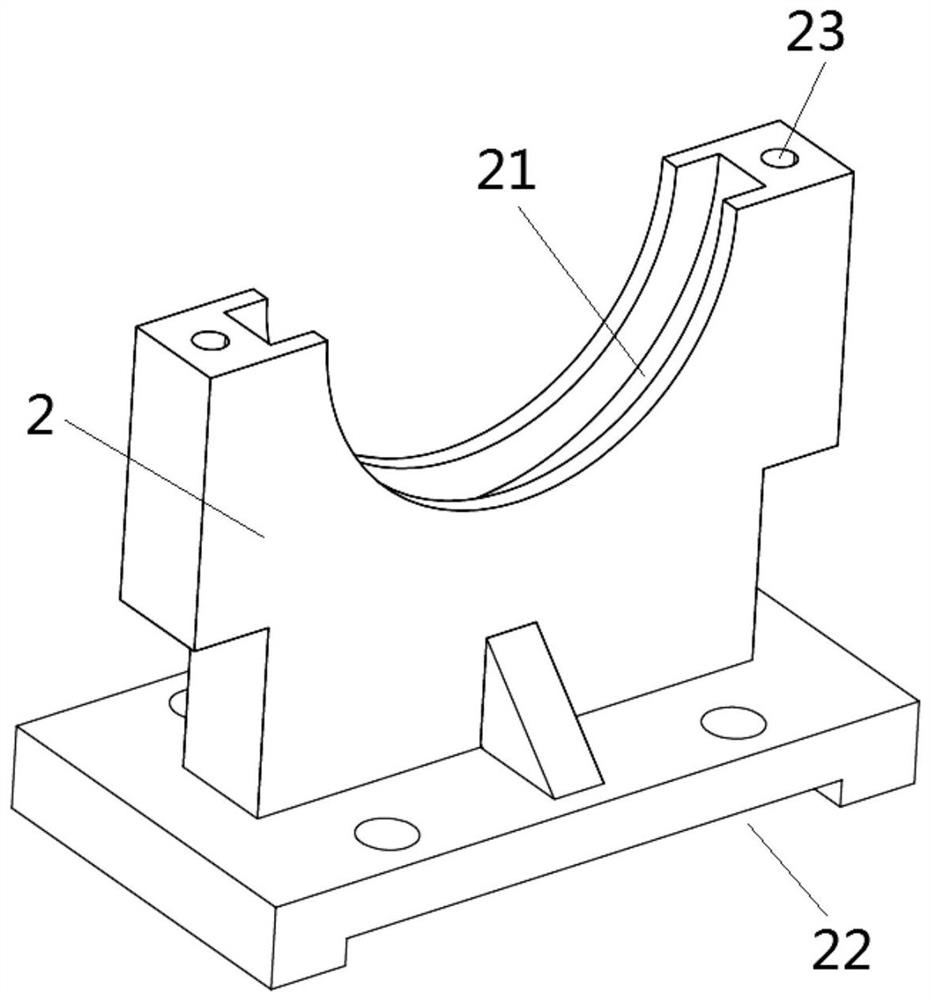

[0045] The pipe fitting welding tool includes a platform 1 , several bases 2 , several upper covers 3 , several copper inner linings 4 and several copper outer linings 5 .

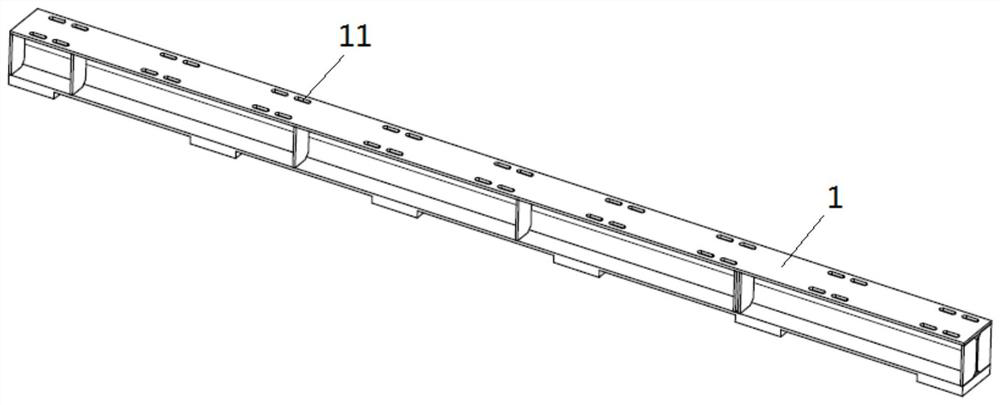

[0046] The platform 1 is located at the bottom of the whole device and is the basis of the whole device, see figure 2 , There are two rows of waist-shaped holes 11 on the upper plane of the platform 1 for fixing the base 2, and the installation distance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com