Colorful optical filter and manufacturing method thereof

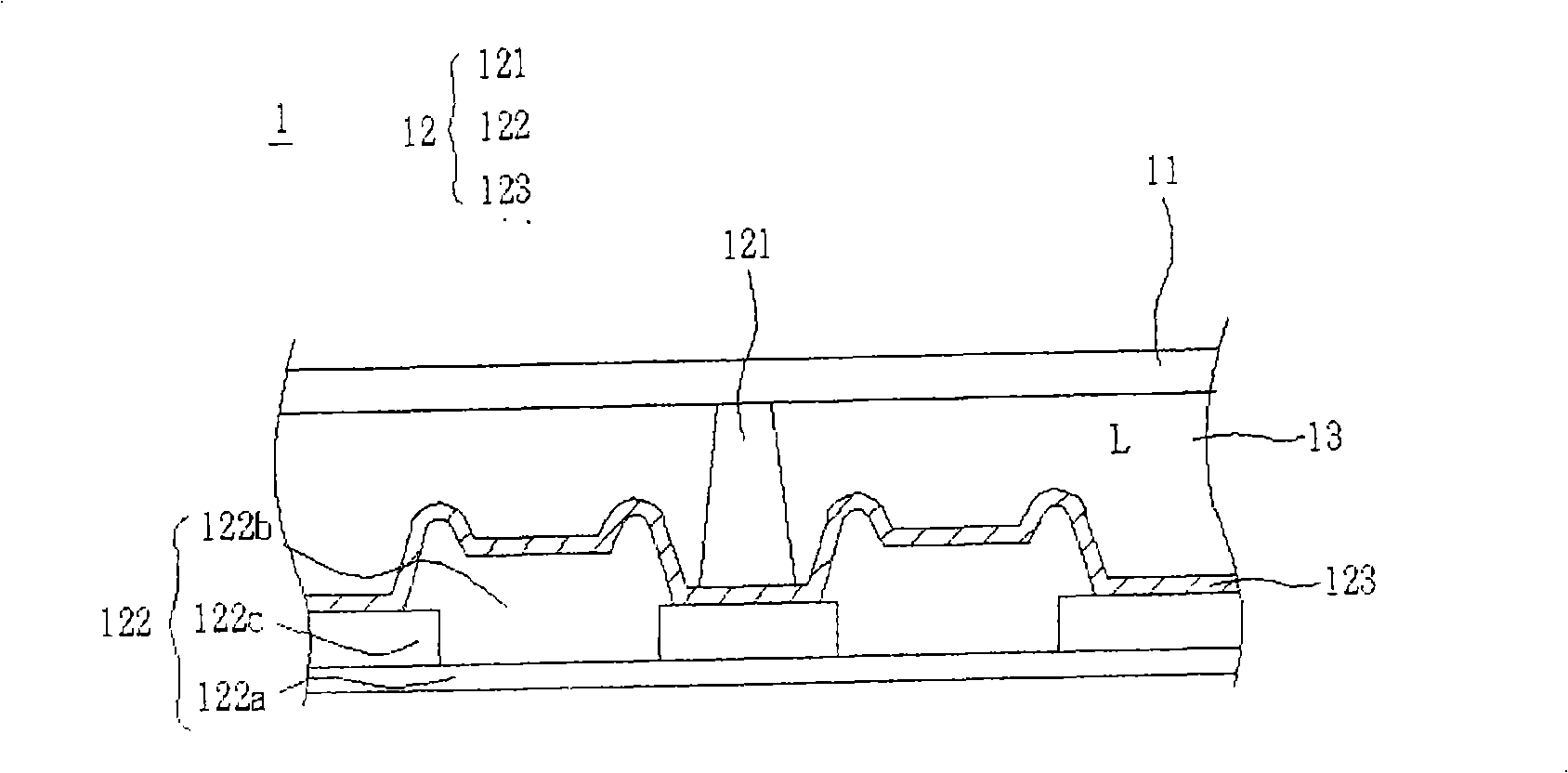

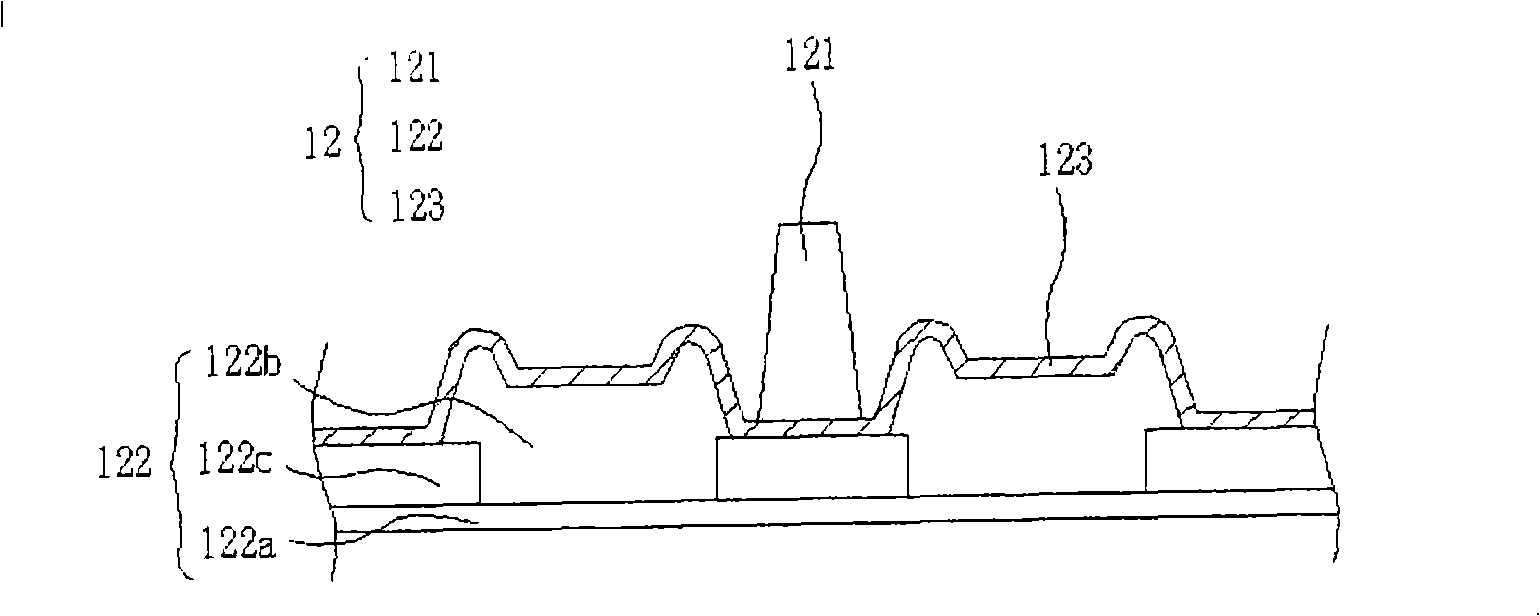

A technology of a color filter and a manufacturing method, which is applied in the field of color filters, can solve the problems of conductive layer 123 cracking and damage, product reliability reduction, crack damage, etc., achieve good industrial applicability, improve production quality, and increase durability pressure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Hereinafter, the color filter and the manufacturing method thereof according to the preferred embodiment of the present invention will be described with reference to related drawings.

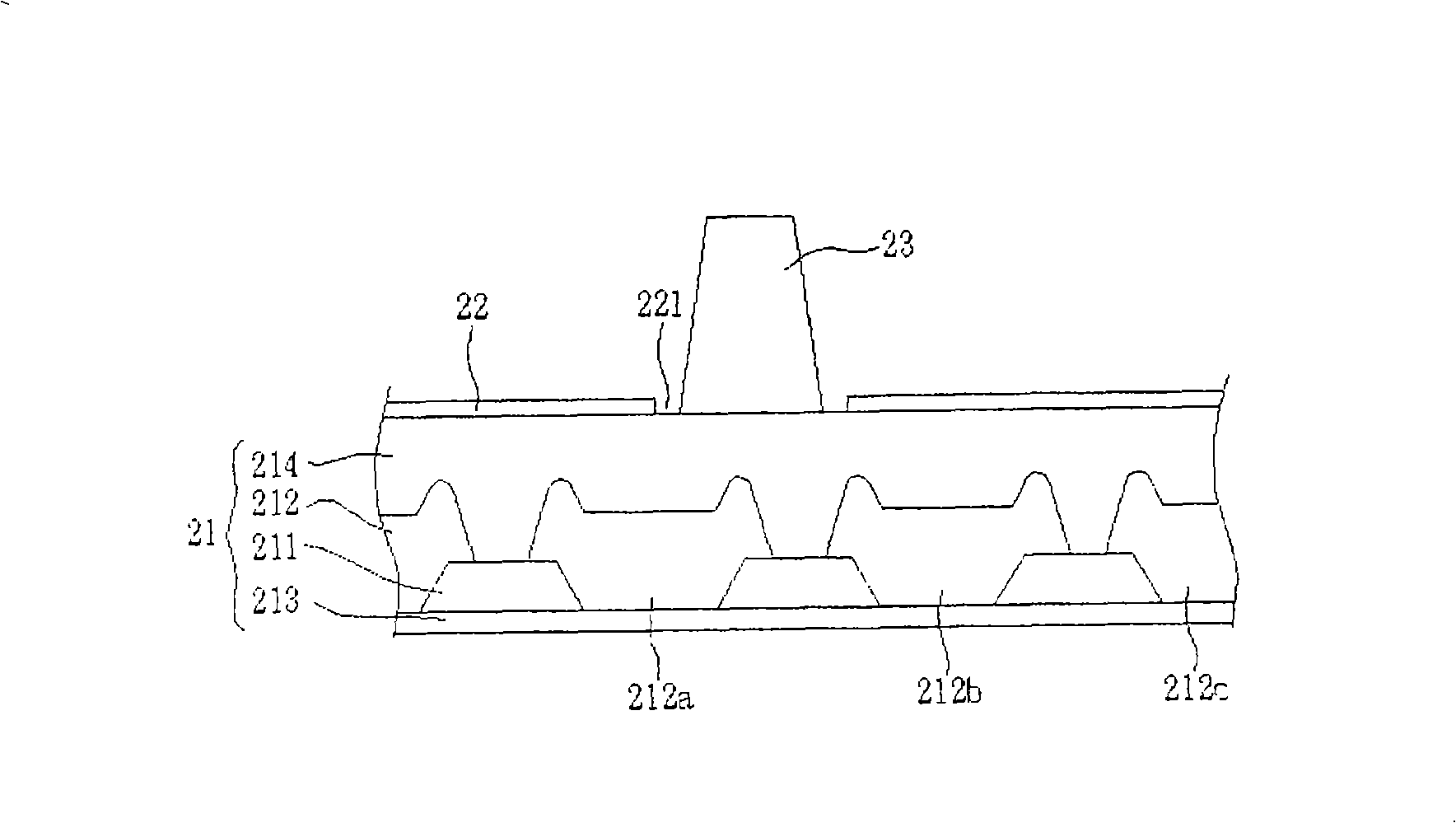

[0050] See image 3 , Is a color filter according to a preferred embodiment of the present invention, which includes a color filter substrate 21, a conductive layer 22, and a spacer 23. In this embodiment, the color filter is applied to the liquid crystal display module.

[0051] The color filter substrate 21 has a light shielding layer 211 and a color filter layer 212. The light-shielding layer 211 is a black matrix (BM), and the material of the black matrix may be resin, chromium, chromium oxide, or chromium oxynitride. In this embodiment, the color filter substrate 21 further includes a substrate 213. The light shielding layer 211 and the color filter layer 212 are disposed on the substrate 213, and the color filter layer 212 covers a portion of the light shielding layer 211. Of course, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com