Monitoring and controlling method and system of solidification structure form of laser additive manufacturing based on pictures

A technology of solidified tissue and laser additive materials, which is applied in the direction of additive processing, additive manufacturing, and process efficiency improvement. It can solve the problems of tissue shape differences, inability to adjust dynamic parameters, and high degree of freedom in manufacturing, so as to achieve the physical correlation of signals. The effect of large size, strong versatility and stability, and fast image processing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

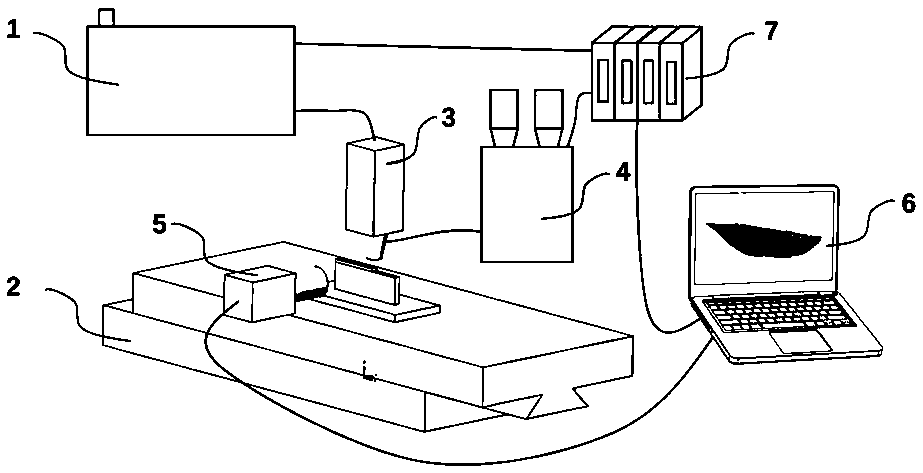

[0045] The present invention will be further described below in conjunction with the accompanying drawings and specific preferred embodiments, but the protection scope of the present invention is not limited thereby.

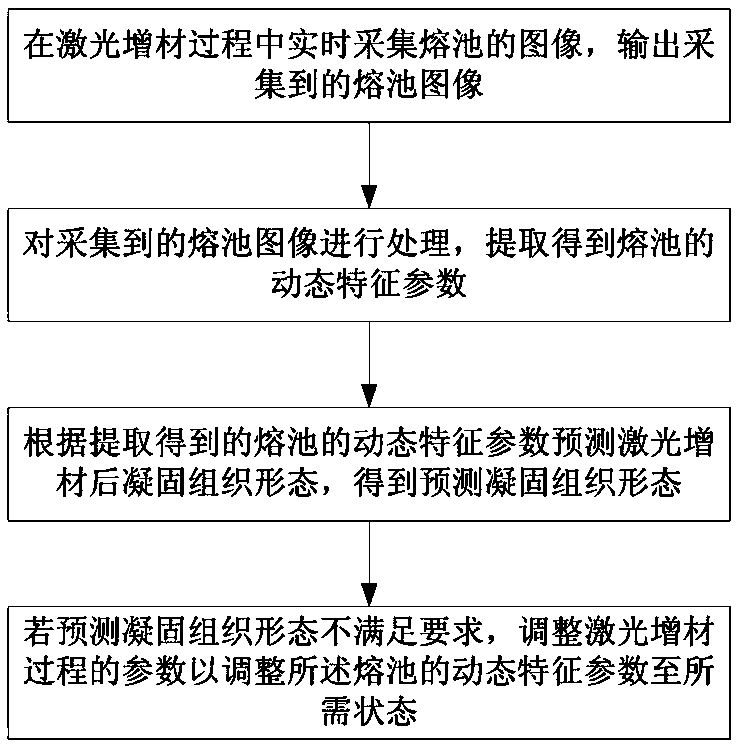

[0046] Such as figure 1 As shown, the method steps of this embodiment based on image monitoring to control the solidified tissue morphology in laser additives include:

[0047] S1. Melting pool image acquisition: collect images of the melting pool in real time during the laser metal additive manufacturing process, and output the collected images of the melting pool;

[0048] S2. Melt pool image processing: process the collected melt pool image and extract the dynamic characteristic parameters of the melt pool;

[0049] S3. Microstructure prediction: Predict the solidified microstructure after laser additive based on the extracted dynamic characteristic parameters of the melt pool, and obtain the predicted solidified microstructure;

[0050] S4. Microstructure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com