Electrostatic resistant heavy duty polyester film and method of preparing the same

A polyester film and antistatic technology, which is applied in the field of film manufacturing, can solve the problems of increasing the complexity of the manufacturing process, unstable antistatic performance, and high probability of problems, and achieves industrial production, excellent appearance, and high manufacturing quality. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

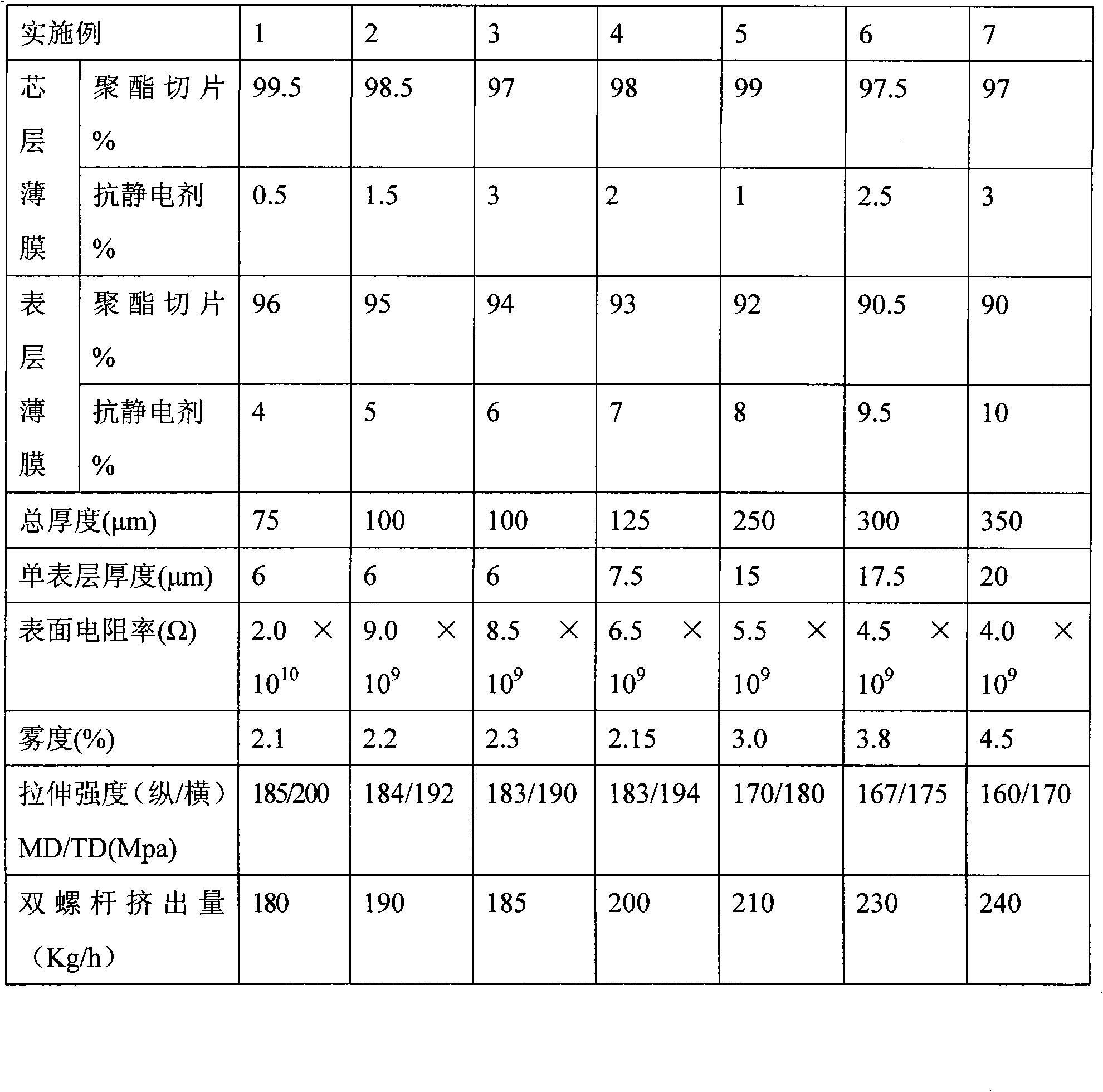

[0011] The antistatic thick polyester film of the present invention comprises a co-extruded three-layer film, and the core layer film has 97-99.5% of polyester chip and 0.5-3% of antistatic agent by weight percentage. The surface film layer has 90-96% polyester chips and 4-10% antistatic agent, the thickness of the core film is 0.075-0.31mm, the thickness of the two surface films is equal, and the thickness of the surface film is 0.006-0.02mm.

[0012] The polyester chips of the present invention adopt bottle-grade or film-grade polyester chips, and the antistatic agent selects polyether type antistatic agents, such as the polyoxyethylene ether system comprising polyamide or polyester amide: polyether ester amide, polyether Amide imide, etc., or methoxypolyethylene glycol methacrylate copolymer: polyethylene oxide, epichlorohydrin copolymer, etc. The antistatic agent can also use ionic antistatic agents, such as quaternary ammonium salts, tetraalkylammonium salts, trialkylalky...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com