Hydraulic support top beam tailor-welding tool

A hydraulic support and top beam technology, applied in the field of tailor welding tooling for hydraulic support top beams, can solve problems such as low production efficiency, many welding defects, and high production costs, and achieve accurate and reliable positioning, small welding deformation, and high product consistency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028]The location and orientation qualifiers such as front, back, left and right in this application all start with Figure 11 The location in is for reference.

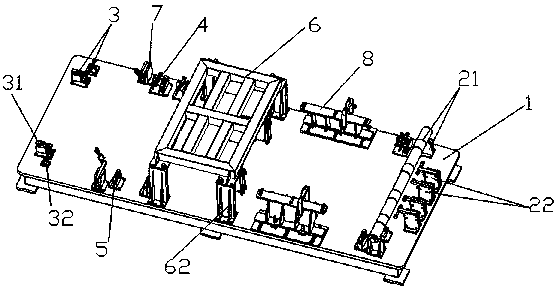

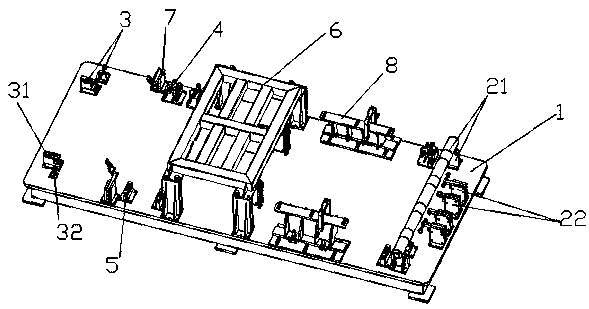

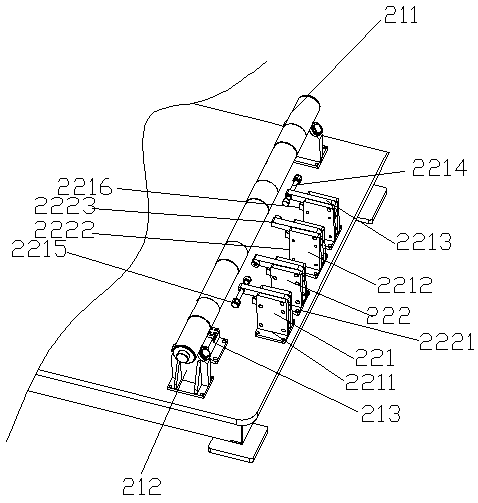

[0029] As shown in the figure, a hydraulic support top beam tailor welding tooling includes a rectangular welding platform 1 and a locking and positioning device 2 located at the front of the rectangular welding platform 1 for fixing the ribs at the head of the hydraulic support top beam 9. The locking positioning device 2 includes a shaft positioning assembly 21 parallel to the short side of the rectangular welding platform 1 and two sets of locking positioning assemblies 22. The shaft positioning assembly 21 includes a positioning shaft 211 and positioning shafts located at the left and right ends of the positioning shaft 211 Seat 212, the positioning shaft 211 is movably clamped in the positioning shaft seat 212, and a support pier 213 is also provided on the inside of the left positioning shaft seat 212, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com