A railway vehicle chassis floor welding process

A rail vehicle and welding process technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve problems such as lack of fusion, cracks, and welding speed effects, and achieve heat dispersion, reduce welding deformation, and reduce welding deformation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

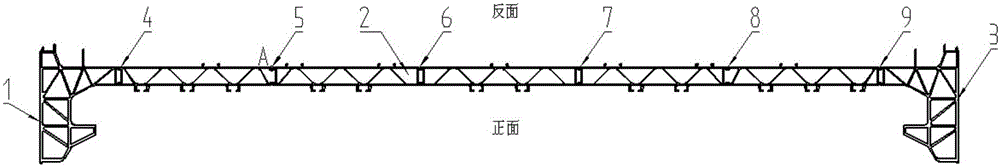

[0035] A rail vehicle underframe floor welding process, the underframe floor includes one side beam 1, two side beams 3, and sandwiched between the one side beam 1 and the two side beams Floor 2, such as Figure 1-Figure 2 shown, including the following steps:

[0036] Step 1: Clean the various profiles of the chassis floor

[0037] Lift the first and second side beams 1, 3 and the middle floor 2 profiles in sequence, and use metal cleaning agent to scrub the parts to be welded and the joints of the profiles;

[0038] Step 2: Locate the various profiles of the chassis floor

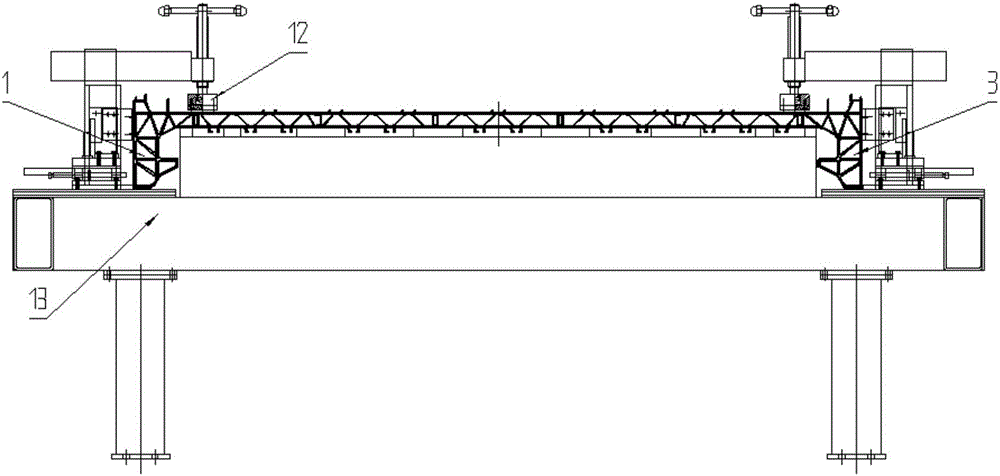

[0039] First, use the pressing device 12 to fix the two-position side beam 3 on the positioning plate 13; secondly, adjust the end faces of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com