Laser welding multifunctional negative pressure gas protection device and method

A gas shielding device and laser welding technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of unstable welding process, uneven forming, burn-through, etc., and achieve the effect of improving surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

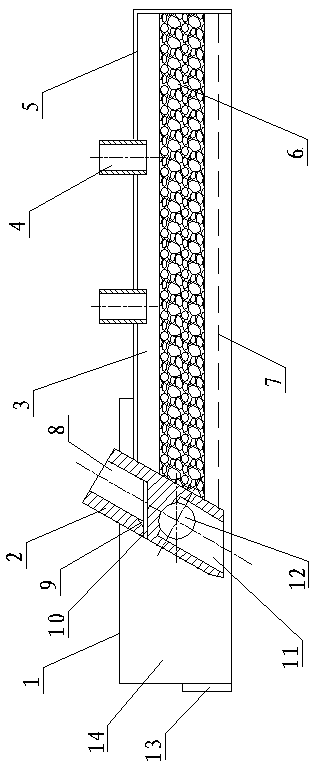

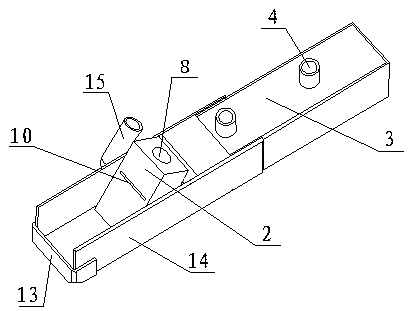

[0028] A laser welding multifunctional negative pressure gas protection device, which consists of: a negative pressure enclosure 1, an isolation shunt cabin 2 is installed in the negative pressure enclosure, and a tail trailing cover is installed on the rear side of the isolation shunt cabin 3. Two intake pipes 4 are respectively installed above the tail trailing hood, a direct protection channel intake pipe 15 is installed on one side of the negative pressure enclosure, and the isolated flow compartment is a square columnar solid structure. , And form an angle of 20°~50° with the vertical direction, the upper part of the isolation split cabin has a compressed air injection chamber 8, a gradual transition structure 9, and a straight-shaped air outlet 10, and a direct gas protection channel below 11 and communicates with the air inlet 12 of the shunt cabin, and the air inlet 12 of the shunt cabin communicates with the air inlet pipe 15 of the direct protection passage.

Embodiment 2

[0030] According to the laser welding multifunctional negative pressure gas protection device according to embodiment 1, the negative pressure enclosure includes a front wall 13, and two side wall 14 are fixed on the inner side of the front wall. The side body of the trailing hood is fixed on the inner side of the enclosure, and the bottom end of the negative pressure enclosure is close to the surface of the welding test panel.

Embodiment 3

[0032] According to the laser welding multifunctional negative pressure gas protection device according to embodiment 1, the tail trailing hood includes a trailing hood shell 5, and the trailing hood shell is a rectangular hollow shell structure, and porous fiber filters are arranged in sequence. Net 6, fine copper net 7, two of the air intake pipes are evenly distributed on the top of the trailing hood shell, and their bottom ends pass through the top wall of the trailing hood shell and extend into the trailing hood shell; on the tail trailing hood shell The plane is rigidly connected with the welding torch body, which can make the welding torch and the protection device form an integrated structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com