Large car frame welding location tyre and large car frame welding technological method

A frame welding and process method technology, applied in the direction of welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of inconvenient detection of welding accuracy, prolong the welding cycle, etc., achieve fast welding speed, improve welding accuracy, and positioning high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings.

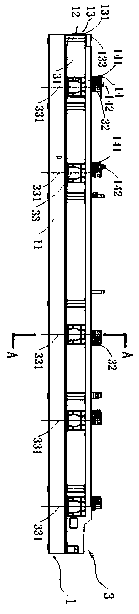

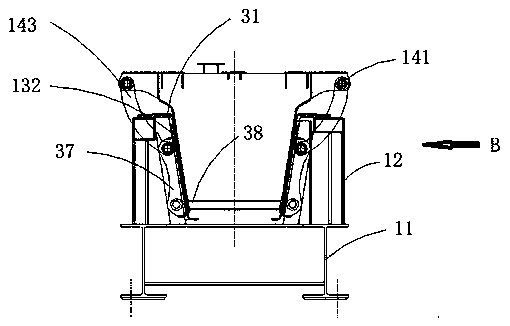

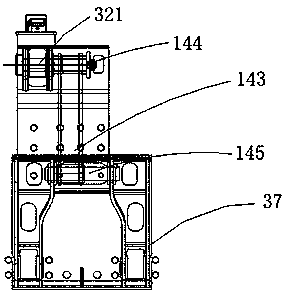

[0031] The present invention firstly discloses a positioning tire for large-scale frame welding. The positioning tire for welding is a combined tire, which includes a basic welding tire I1 and a positioning detection tire II2. The basic welding tire I1 is used to assemble the longitudinal beam 31, the beam 32, The swing arm support part 37 and the cross brace part 38 have the functions of positioning detection tire II2; 1) visually inspect whether the accuracy of the key parts of the main body of the frame assembled by the basic welding tire I1 meets the requirements, and use the position detection tire II2 to correct the unqualified welding. 2) further assemble and weld components such as the rear outrigger 34, the front outrigger 35 and the front section 36 of the vehicle frame on the main body of the vehicle frame to complete the vehicl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com