Aluminum alloy grating and welding process thereof

An aluminum alloy and welding tooling technology is applied in the field of aluminum alloy grids and welding to manufacture the aluminum alloy grids, which can solve the problems of difficult operation, too many links, welding deformation, etc., so as to reduce welding deformation and improve production. Efficiency, the effect of improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

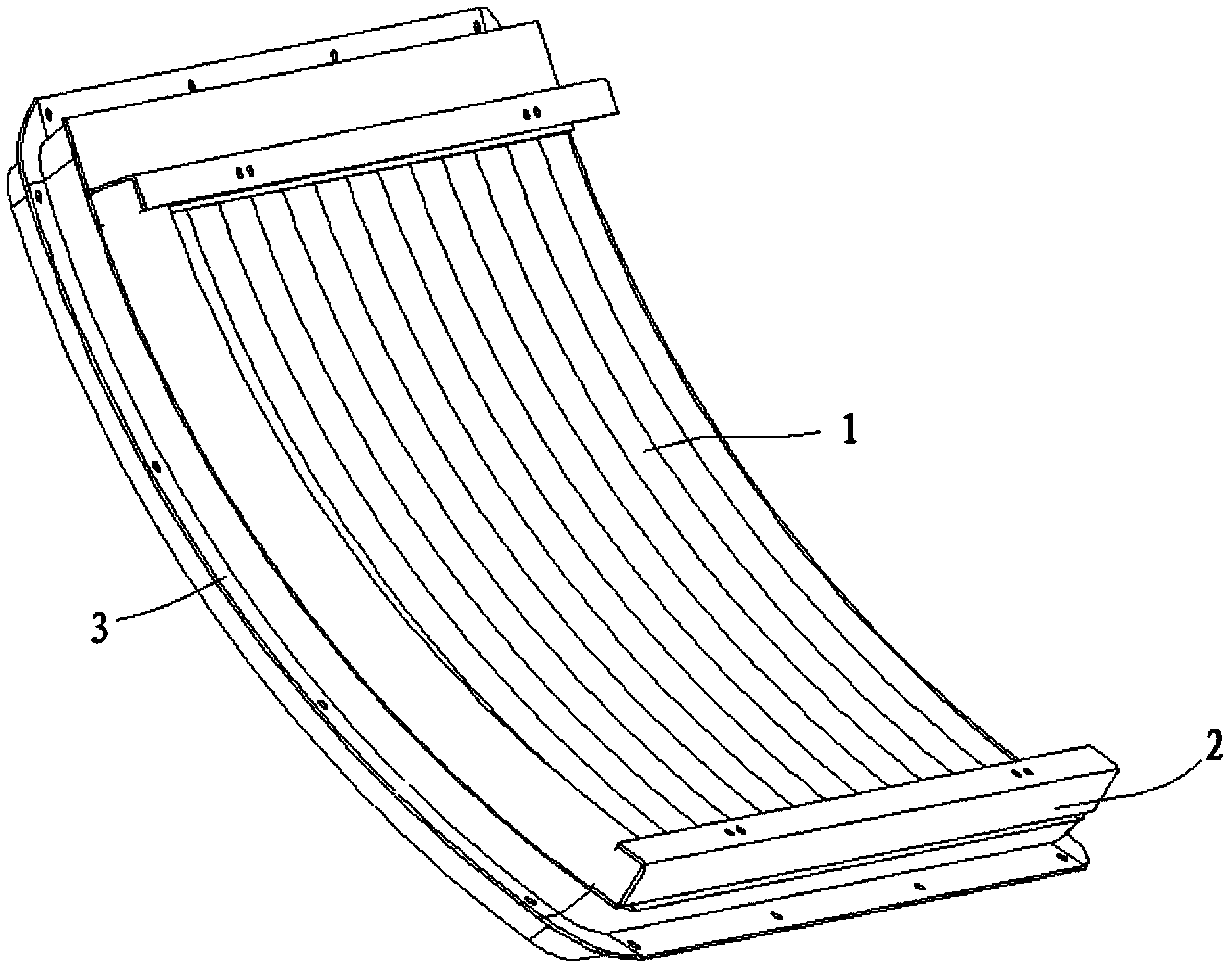

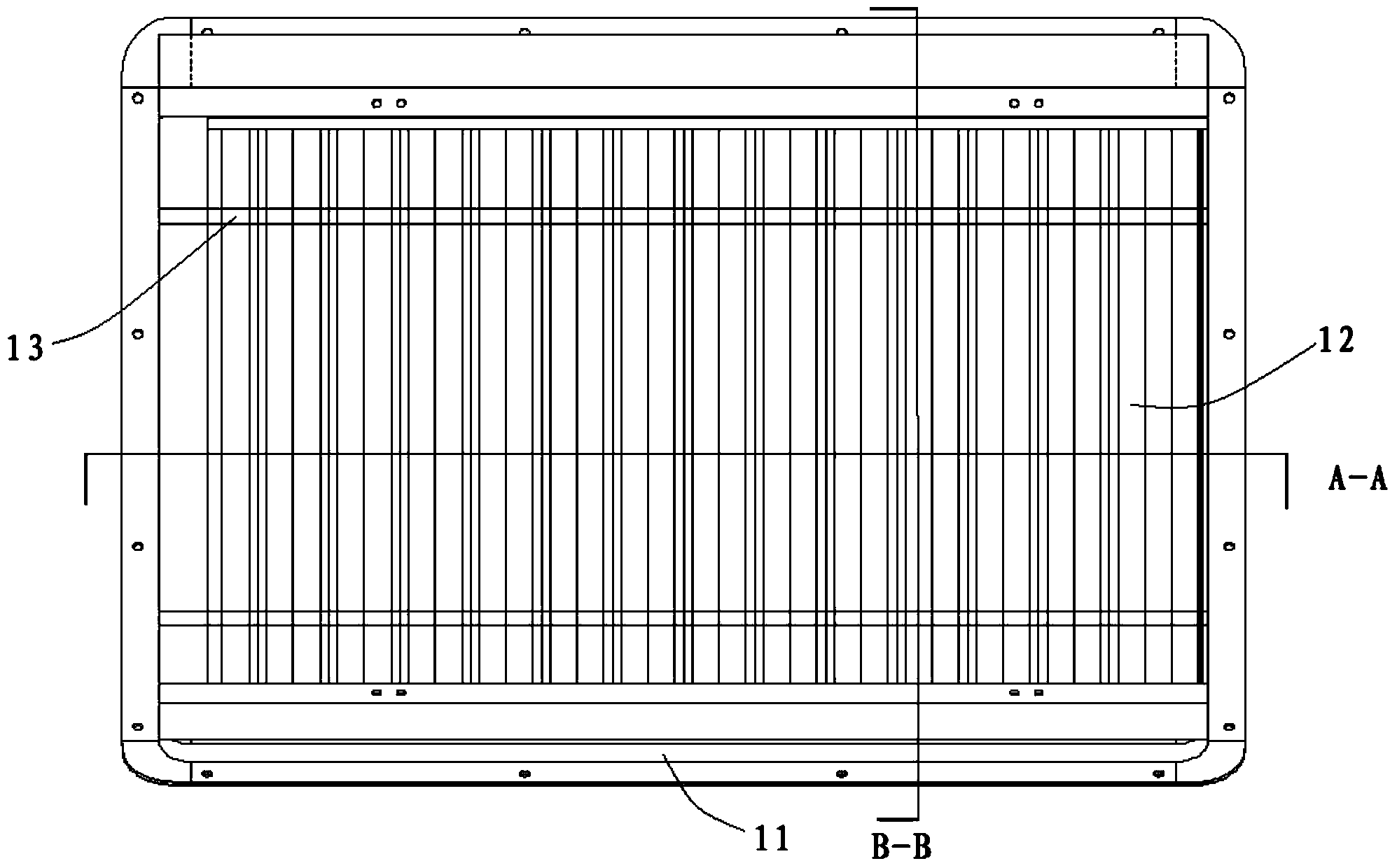

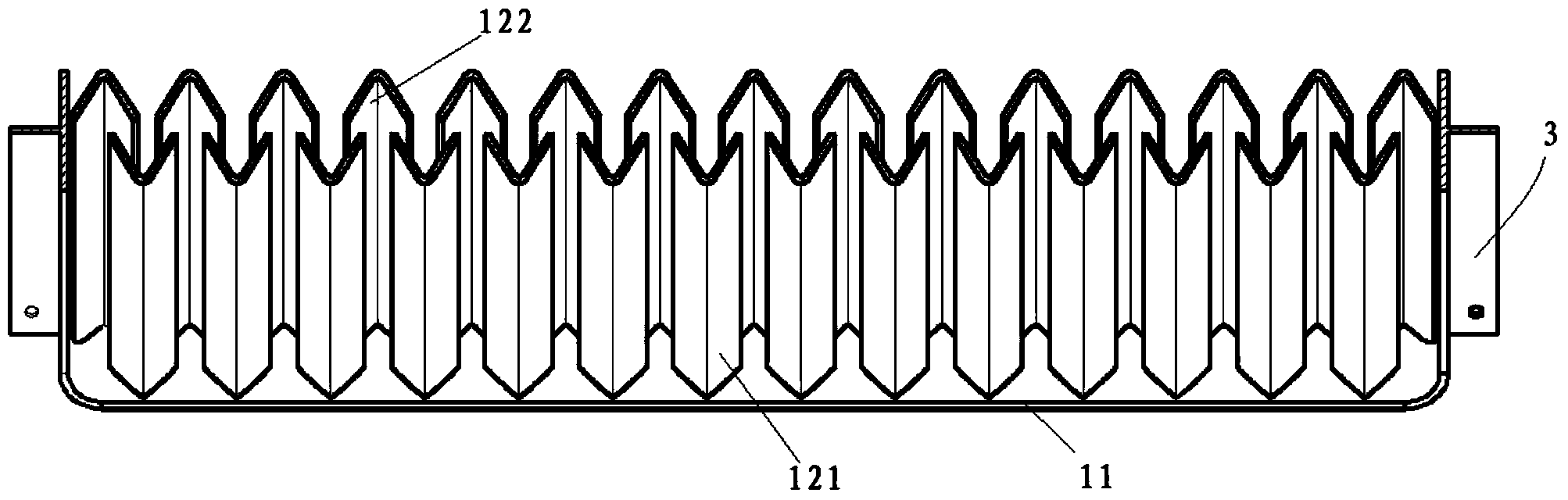

[0038] Such as Figure 1-10 As shown, the aluminum alloy grille of this embodiment includes a grille body 1 and a filter frame 2. The grille body 1 includes a frame 11 and a V-shaped bar 12. The number of the V-shaped bars 12 is multiple and parallel to each other. It includes an upper V-shaped bar 121 and a lower V-shaped bar 122. The notches of the upper V-shaped bar 121 and the lower V-shaped bar 122 are opposite and the two ends are welded and fixed on the inner wall of the frame 11. The filter frame 2 is welded and fixed on the side of the frame 11 wall.

[0039] In this implementation, the grille profiles are all 6005A-T6 profiles.

[0040] In this implementation, the upper and lower V-shaped bars are arranged alternately.

[0041] In this implementation, between the upper V-shaped bar 121 and the lower V-shaped bar 122, a reinforcing rib is arranged perpendicular to the direction of the V-shaped bar 12. Welding connection, the two ends of the reinforcing rib are weld...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com