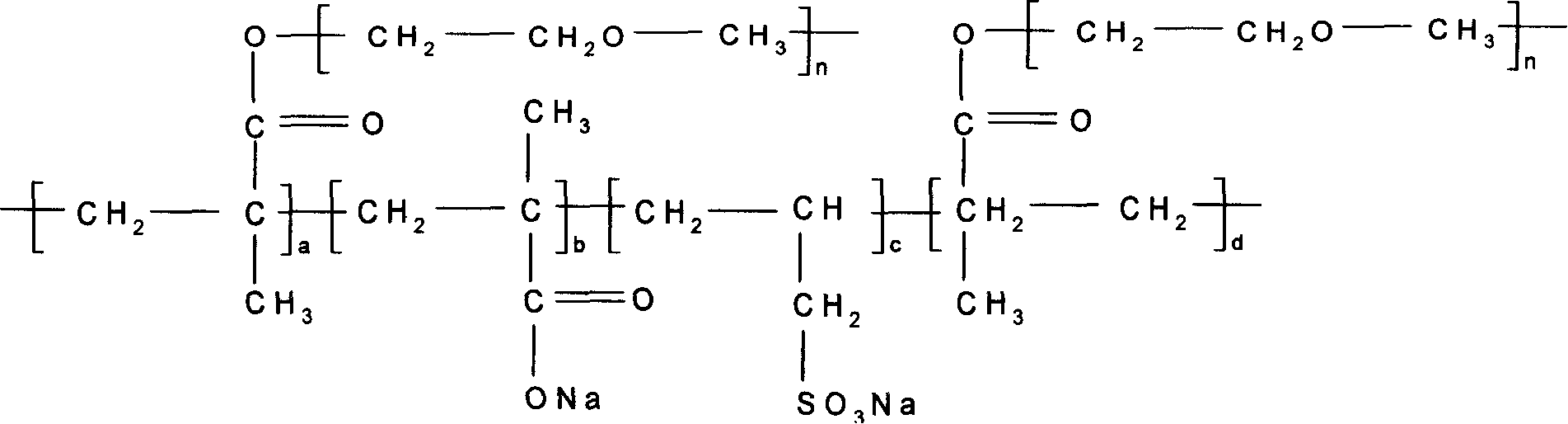

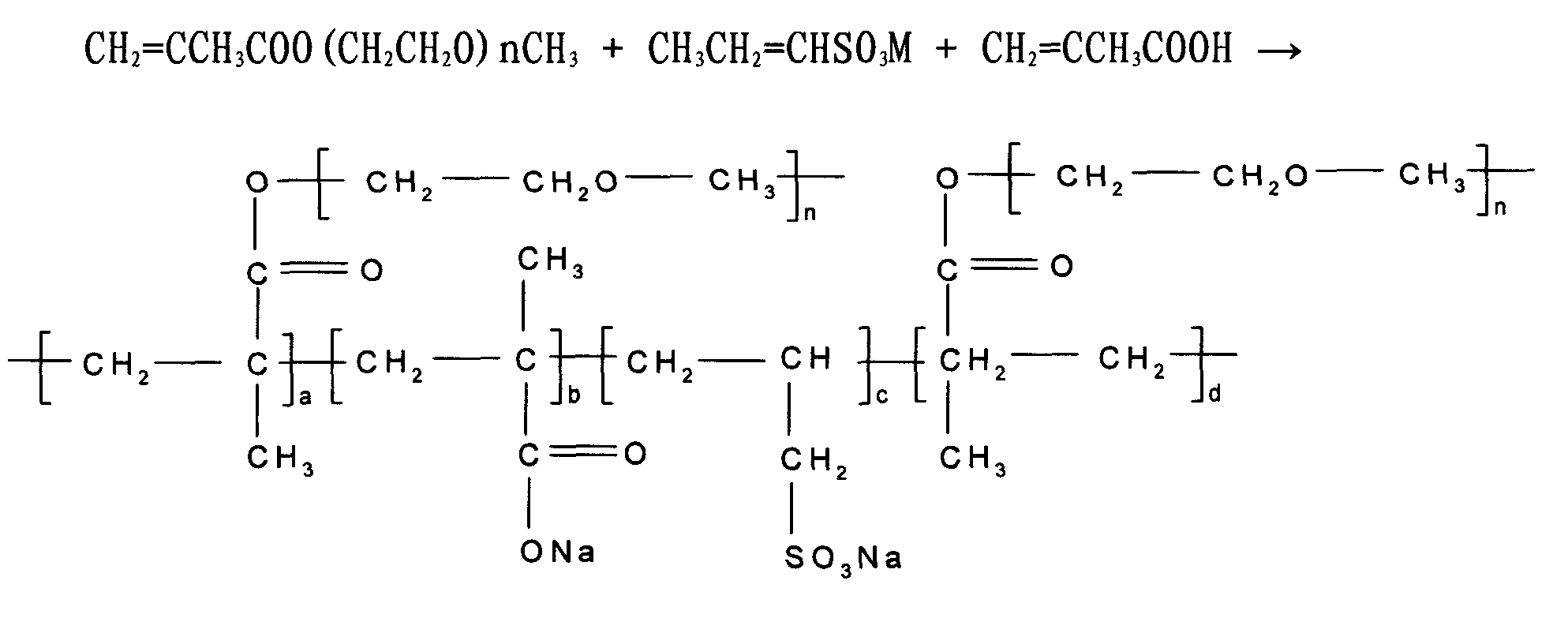

Polycarboxylic acids series concrete high efficiency water reducing agent and synthesizing process

A high-efficiency water-reducing agent and polycarboxylic acid-based technology, which is applied in the field of polymer carboxylic acid grafting-type high-efficiency water-reducing agent and its synthesis, can solve the problems of environment, human body hazards, high equipment requirements, harsh reaction conditions, etc. , to achieve the effect of freeze-thaw resistance and concrete durability improvement, long-term storage without precipitation, and good apparent quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

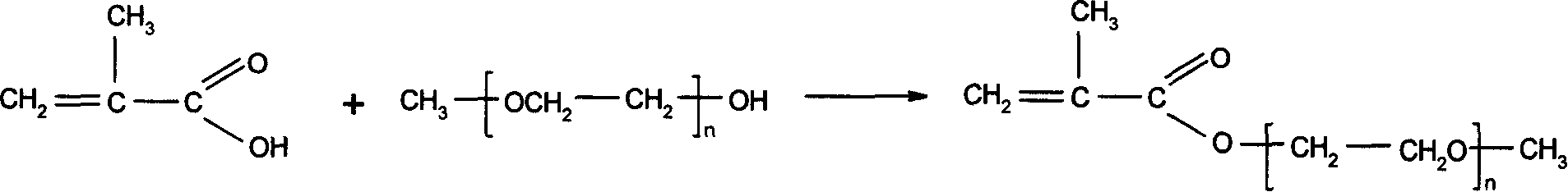

[0025] Into a 1000mL four-neck flask equipped with a thermometer, a stirrer, and a reflux condenser, add 90g of methacrylic acid, 400g of polyethylene glycol monomethyl ether, 2.7g of concentrated sulfuric acid, 1.5g of p-toluenesulfonic acid and an appropriate amount of polymerization inhibitor agent, feed nitrogen at 120-140° C., keep warm for 3-6 hours, and cool for later use to prepare macromonomer polyethylene glycol monomethyl methacrylate (MPEGMA). In another 1000mL four-neck flask, first add 380g of deionized water, then add 180-240g of MPEGMA, heat at 80-90°C, add 20g of comonomer methacrylic acid, 4.0-10g of initiator ammonium persulfate and chain Transfer agent mercaptoethanol 1 ~ 3g, drop it within 4 ~ 5 hours, continue to heat and mature for 1 ~ 3 hours after the drop, to complete the reaction, remove the system, neutralize with alkali after cooling, and obtain a light brown transparent viscous liquid. The solid content is around 25%.

[0026] When the measured m...

Embodiment 2

[0028] Add 90g of methacrylic acid, 400g of polyethylene glycol monomethyl ether, 5.4g of concentrated sulfuric acid, and an appropriate amount of polymerization inhibitor into a 1000mL four-necked flask equipped with a thermometer, a stirrer, and a reflux condenser. ~140°C, keep warm for 3~6 hours, cool for later use, and prepare macromonomer polyethylene glycol monomethyl methacrylate (MPEGMA). In another 1000mL four-neck flask, first add 380g of deionized water, then add 180-240g of MPEGMA, heat at 80-90°C, add dropwise 20g of comonomer methacrylic acid, 15g of sodium propylene sulfonate, and initiator persulfate Ammonium 4.0 ~ 10g and chain transfer agent mercaptoethanol 1 ~ 2g, drop in 4 ~ 5 hours, continue to heat and mature for 1 ~ 3 hours after the drop, to complete the reaction, remove the system, neutralize with alkali after cooling, and get shallow Brown transparent viscous liquid with a solid content of about 25%.

[0029] It is measured that when the mixing amoun...

Embodiment 3

[0031] Into a 1000mL four-neck flask equipped with a thermometer, a stirrer, and a reflux condenser, add 90g of methacrylic acid, 400g of polyethylene glycol monomethyl ether, 5.2g of p-toluenesulfonic acid, and an appropriate amount of polymerization inhibitor. Nitrogen at 120-140° C., heat preservation for 3-6 hours, and cool for later use to prepare macromonomer polyethylene glycol monomethyl methacrylate (MPEGMA). In another 1000mL four-necked flask, first add 380g of deionized water, then add 180-240g of MPEGMA, heat at 80-90°C, add dropwise comonomer acrylic acid 25g, acrylamide 7g, initiator ammonium persulfate 5.0-10g And chain transfer agent mercaptoethanol 1~2g, drop it within 4~5 hours, continue to heat and mature for 1~3 hours after dropping, to make the reaction complete, remove the system, neutralize it with alkali after cooling, and get light brown transparent viscosity Liquid, the solid content is about 25%.

[0032]It is measured that when the mixing amount i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com