Sloping bottom step comprehensive heating furnace

The technology of a walking heating furnace and heating furnace is applied in the direction of heat treatment furnace, furnace, furnace type, etc., which can solve the problems of high cost of walking heating furnace, high labor intensity of workers, unstable product quality, etc., so as to save gas. , the effect of reducing the number of people and labor intensity, and saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

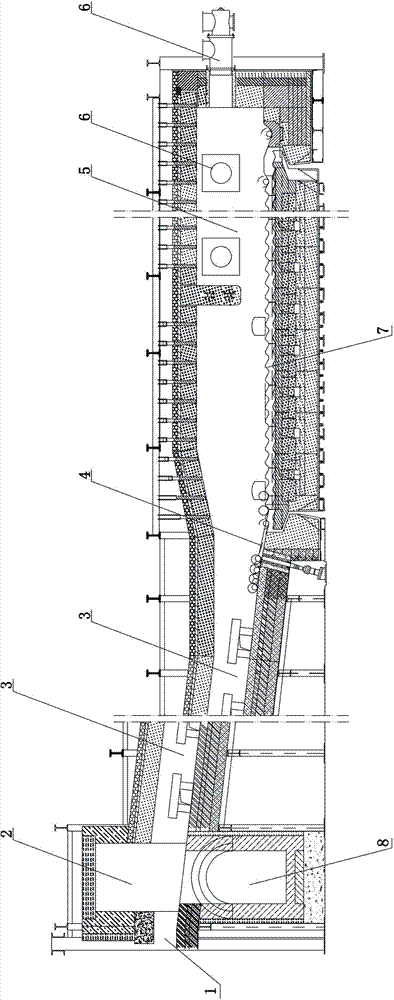

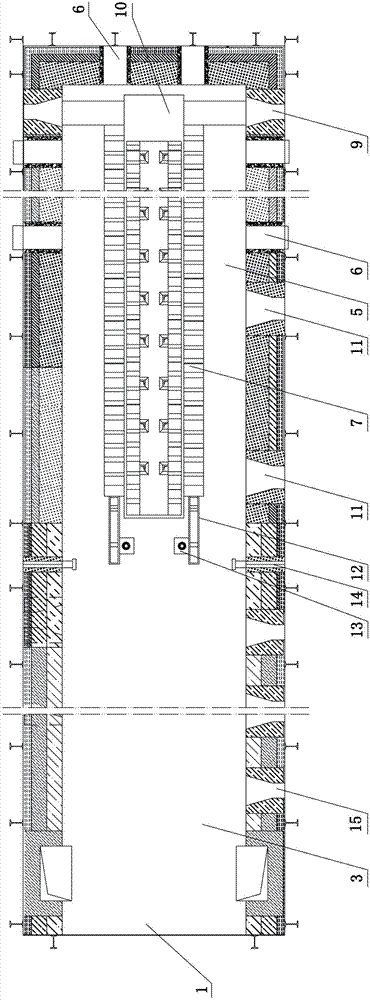

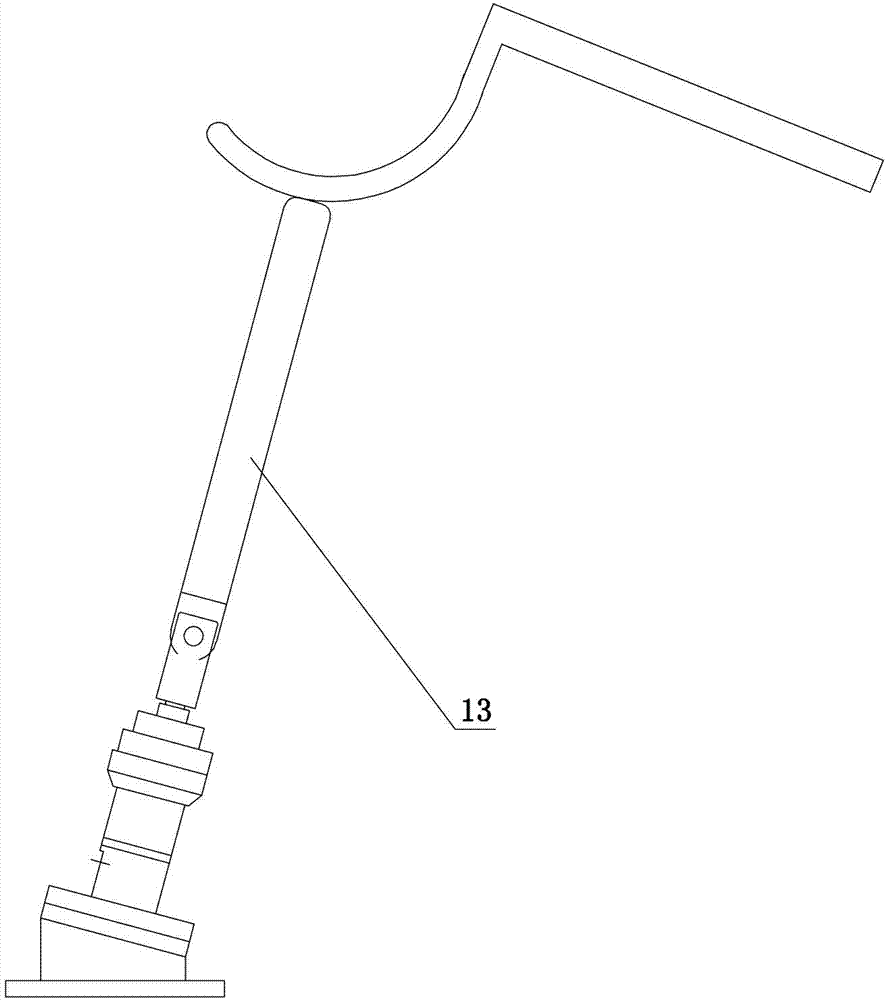

[0025] see figure 1 , 2 , the present invention includes a preheating zone, a heating zone, and a soaking zone, particularly: the preheating zone adopts an inclined-bottom heating furnace 3 structure, and the heating zone and the soaking zone adopt a walking heating furnace 5 Structure, the low end of the inclined bottom heating furnace 3 and the front end of the walking heating furnace 5 are butted into one body, and the high end of the inclined bottom heating furnace 3 is provided with a feed port 1, which is close to the feed port 1 and above the bottom of the furnace A smoke storage room 2 is provided, and a flue inlet 8 is provided below the bottom of the furnace to communicate with the smoke storage room 2. The bottom of the inclined-bottom heating furnace 3 is a slope with a single slope. The walking heating furnace 5 The bottom of the furnace is provided with a walking conveying mechanism 7, and a discharge mechanism 10 and a discharge port 9 are provided at the tail ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com