Roller bottom type saw web quenching line

A roller bottom type, saw blade technology, applied in the direction of quenching agent, quenching device, furnace type, etc., can solve problems such as failure to achieve mechanical properties, and achieve the effects of convenient equipment maintenance, improved water utilization, and long life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

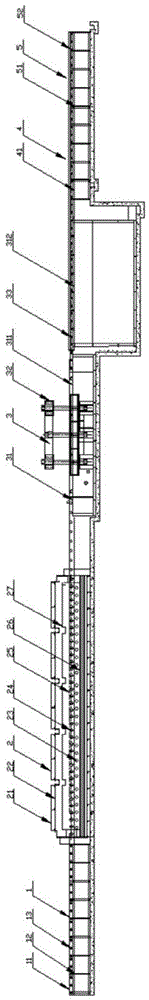

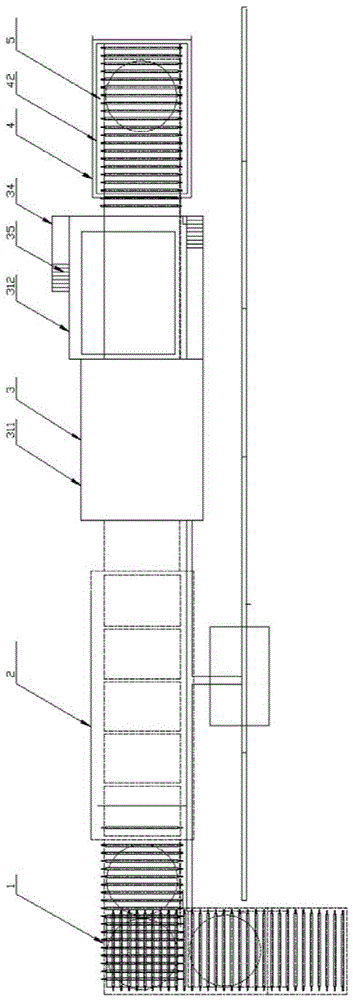

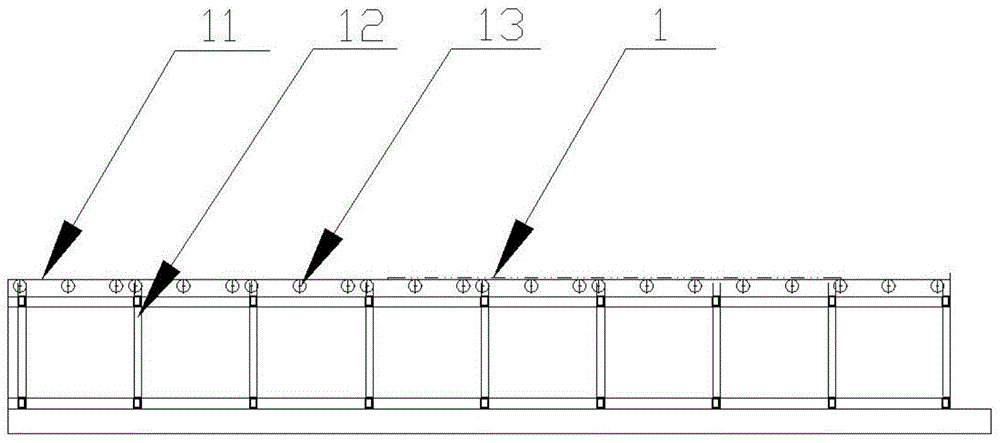

[0020] refer to Figure 1-Figure 6 , a roller bottom type saw blade quenching line, comprising a feeding table 1, a heating furnace 2, an automatic quenching and flattening system 3, a discharge cleaning tank 4 and a discharge table 5 connected in sequence, and the feed table 1 is composed of a shell Body 11, section steel welding forming frame 12 and feed roller 13, bearings and bearing seats are installed horizontally on both sides of feed roller 13 to ensure that the workpiece runs smoothly and does not run sideways. The heating furnace 3 is mainly composed of furnace Shell 21, furnace lining 22, radiant tube electric heating element 23, driving roller 24, transmission mechanism 25, protective atmosphere pipeline system 26 and uniform fan 27, the driving roller 24 is set in the furnace shell 21 for supporting and Convey the workpiece, and horizontally level the drive roller 24 on the same level. The automatic quenching and flattening system 3 is mainly composed of an oil ta...

Embodiment 2

[0023] refer to Figure 1-Figure 6 , a roller bottom type saw blade quenching line, comprising a feeding table 1, a heating furnace 2, an automatic quenching and flattening system 3, a discharge cleaning tank 4 and a discharge table 5 connected in sequence, and the feed table 1 is composed of a shell Body 11, section steel welding forming frame 12 and feed roller 13, bearings and bearing seats are installed horizontally on both sides of feed roller 13 to ensure that the workpiece runs smoothly and does not run sideways. The heating furnace 3 is mainly composed of furnace Shell 21, furnace lining 22, radiant tube electric heating element 23, driving roller 24, transmission mechanism 25, protective atmosphere pipeline system 26 and uniform fan 27, the driving roller 24 is set in the furnace shell 21 for supporting and Convey the workpiece, and horizontally level the drive roller 24 on the same level. The automatic quenching and flattening system 3 is mainly composed of an oil ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com