Stirring/flow-guiding multi-phase reactor

A diversion multiphase, reactor technology, applied in the field of reactors, can solve the problems of insufficient material mixing, large power consumption, unsatisfactory effect, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

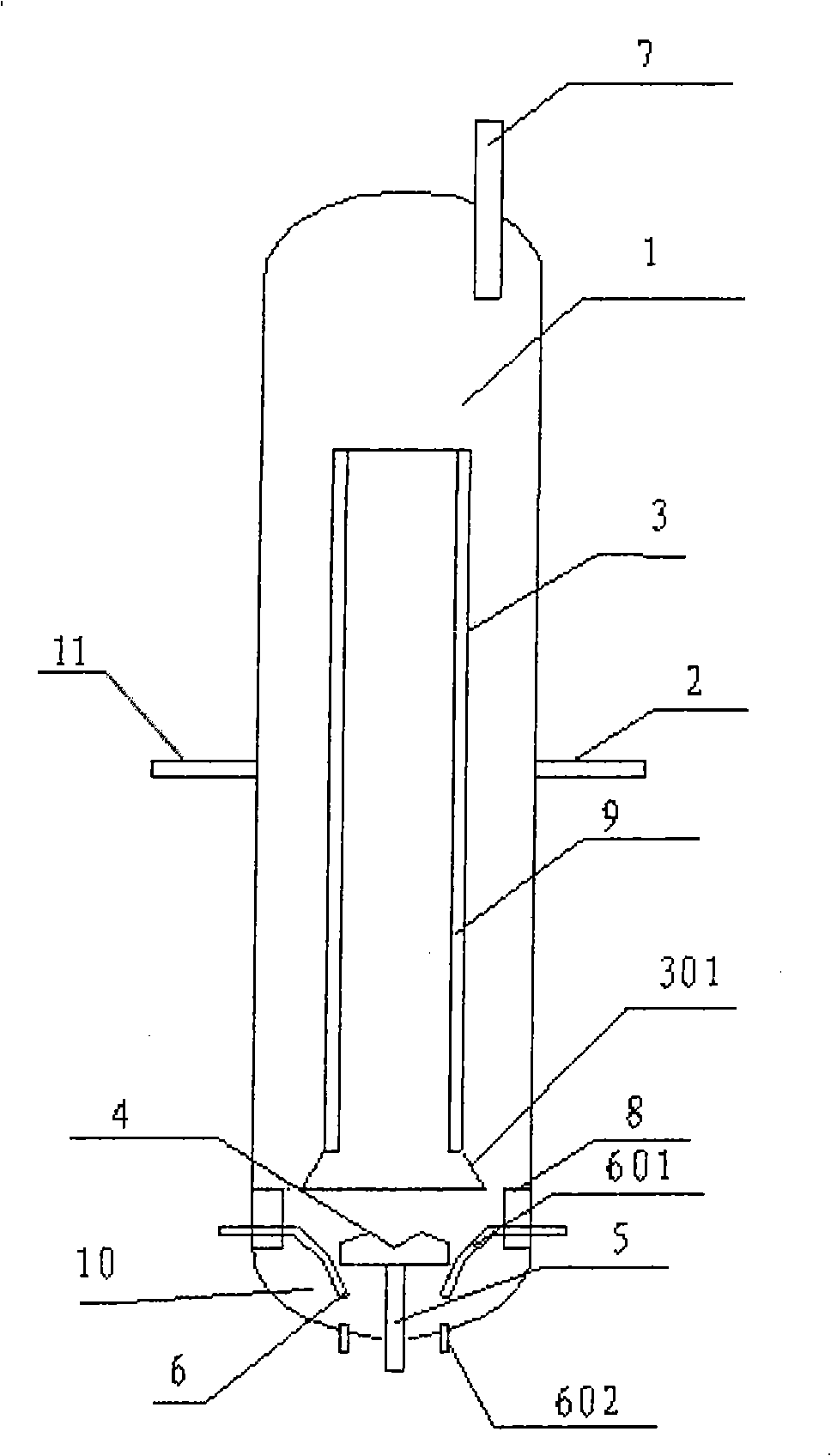

[0017] see figure 1 , the stirring / guiding heterogeneous reactor of the present invention, comprising:

[0018] A cylindrical airtight housing 1 provided with a material outlet device 2 and a liquid phase inlet device 11, preferably, the liquid phase inlet device 11 is arranged at or below the middle of the housing 1;

[0019] A guide tube 3 arranged in the lower part of the housing 1, the outer diameter of which is smaller than the inner diameter of the housing 1, and a gap 10 is left between the guide tube 3 and the bottom of the housing 1;

[0020] A stirring device comprising a stirring shaft 5 and a paddle 4 fixed on the stirring shaft 5 is arranged in the gap 10 between the draft guide cylinder 3 and the bottom of the housing 1, the stirring shaft 5 passes through the bottom of the housing 1 and extend to the outside of the casing 1;

[0021] A gas inlet device arranged on the bottom and / or side wall of the housing 1, the gas outlet 6 of the gas inlet device is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com