Stepping-bottom-type heating furnace

A walking bottom heating furnace technology, which is applied to lighting and heating equipment, furnaces, furnace types, etc., can solve the problems of easy deformation of the load-bearing frame, easy damage of furnace bottom refractory materials, maintenance and oven cycle, and water leakage at the bottom of the furnace, etc. To achieve the effect of improving production efficiency, shortening the construction period and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

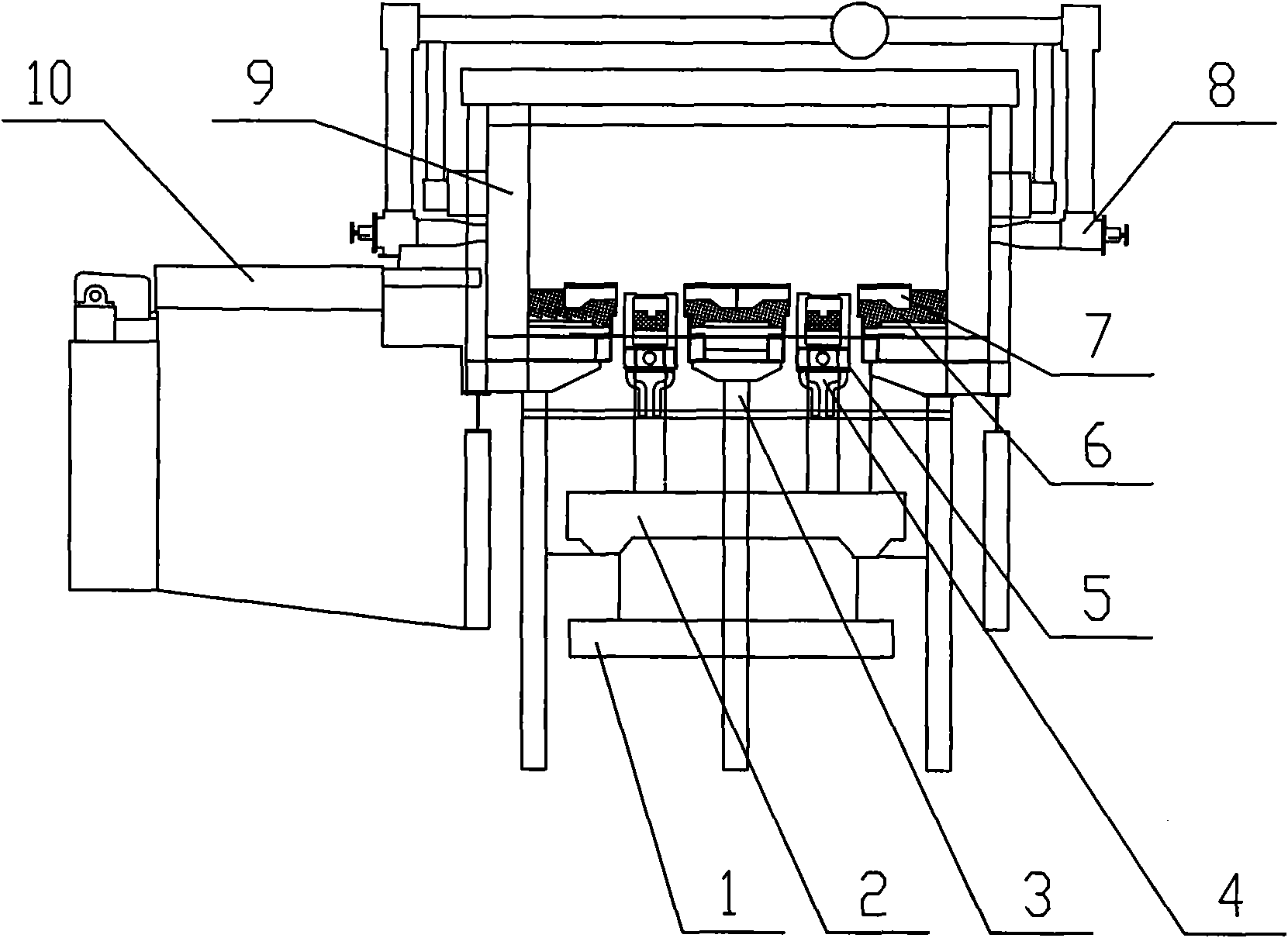

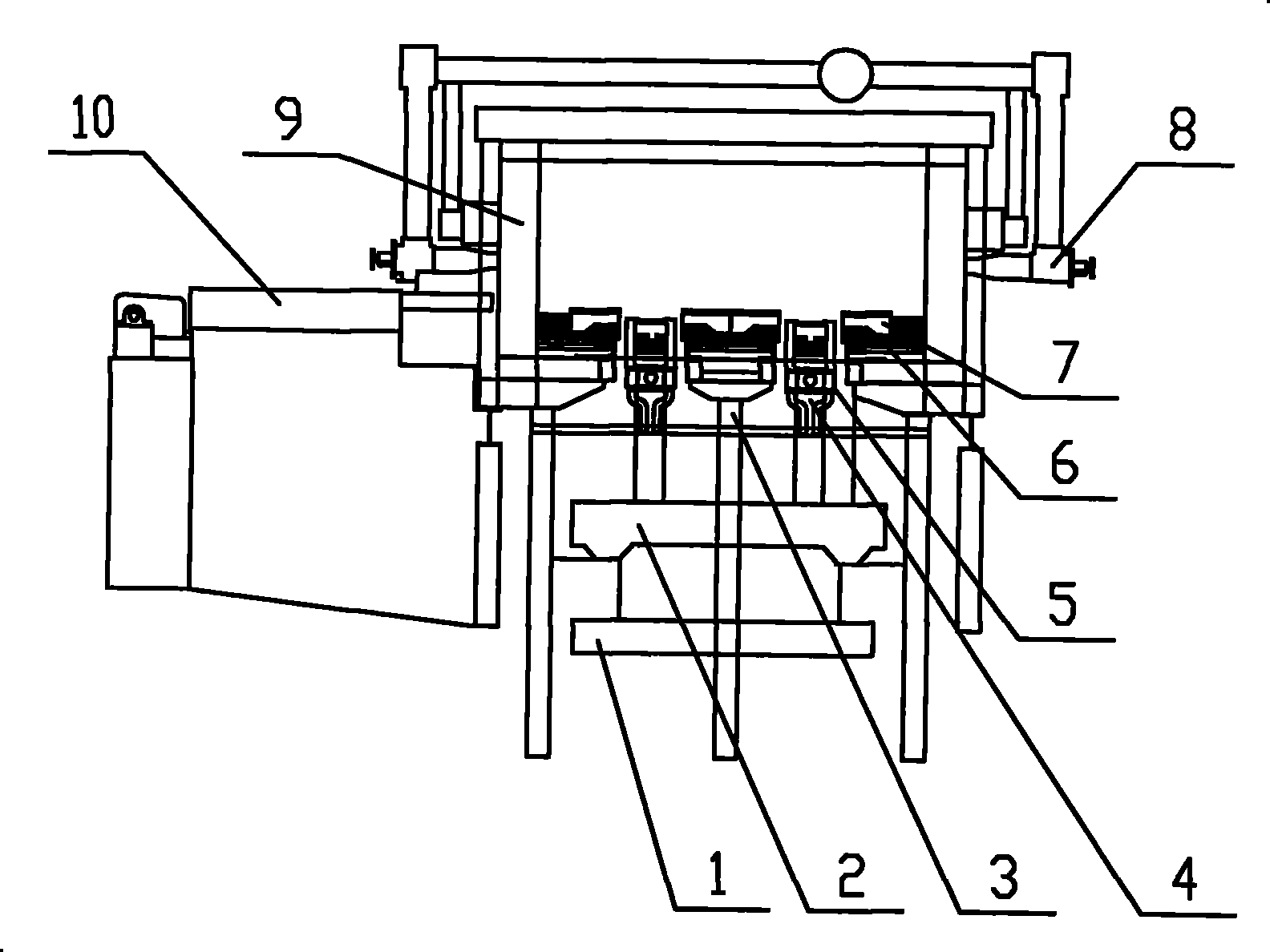

[0010] As shown in Figure 1, the present invention includes a furnace body 9, a combustion system 8, a fixed bottom 3, a movable bottom 4, a translation frame 2, a lifting frame 1 and a steel loading machine 10, and the fixed bottom 3 and the movable bottom 4 are equipped with Prefabricated block 7 for supporting and positioning the workpiece to be heated.

[0011] The fixed bottom 3 and the movable bottom 4 include a frame-shaped load-bearing rectangular square tube 5, and the rectangular square tube 5 communicates with cooling water.

[0012] The lower part of the prefabricated block 7 arranged on the fixed bottom 3 and the movable bottom 4 is provided with a boss, and the upper part is provided with an arc-shaped groove adapted to the shape of the heated workpiece; the upper surface of the fixed bottom 3 and the movable bottom 4 is provided with a There are several grooves; the boss at the bottom of the prefabricated block 7 is connected with the grooves on the fixed bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com