Predictive maintenance information feedback method and device for automobile manufacturing equipment

A technology for automobile manufacturing and maintenance information, applied in forecasting, manufacturing computing systems, instruments, etc., can solve problems such as poor performance of automobile manufacturing equipment, inability to accurately determine automobile manufacturing equipment, etc., and achieve the effect of improving the effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

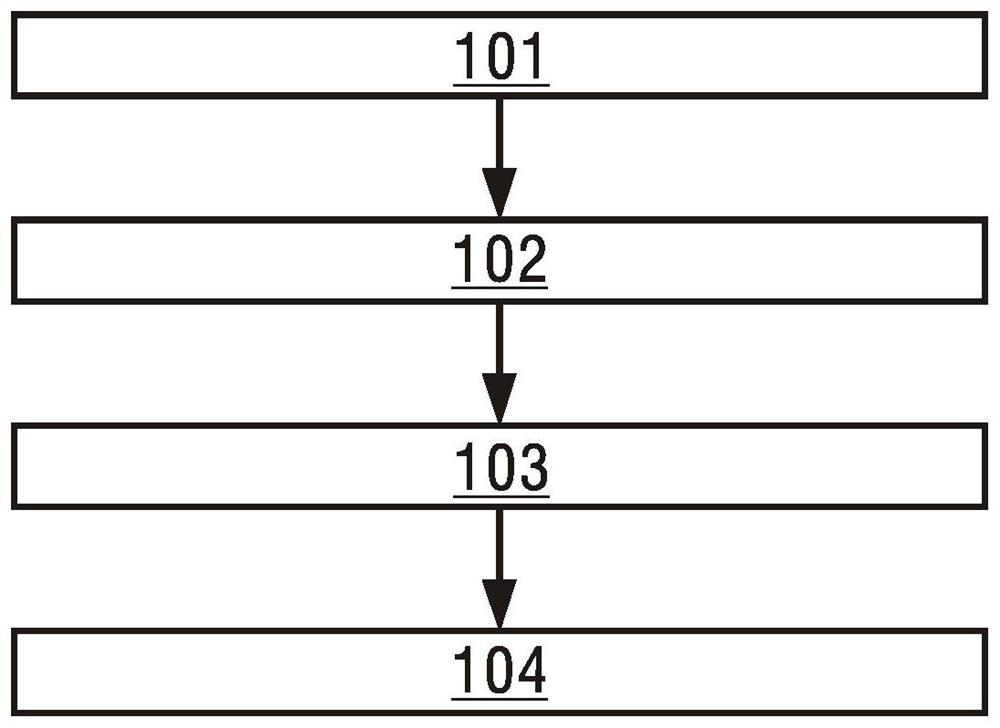

Image

Examples

Embodiment Construction

[0082] As mentioned above, when predictive maintenance is currently performed on automobile manufacturing equipment, maintenance personnel conduct regular inspections on each automobile manufacturing equipment. During the inspection process, it is determined whether the automobile manufacturing equipment needs predictive maintenance based on experience. The factory is equipped with a large number of automobile manufacturing equipment, but the number of maintenance personnel is limited and the experience levels of different maintenance personnel are different. Relying on the experience of maintenance personnel cannot accurately determine all the automobile manufacturing equipment that needs predictive maintenance. Resulting in less effective predictive maintenance of automotive manufacturing equipment.

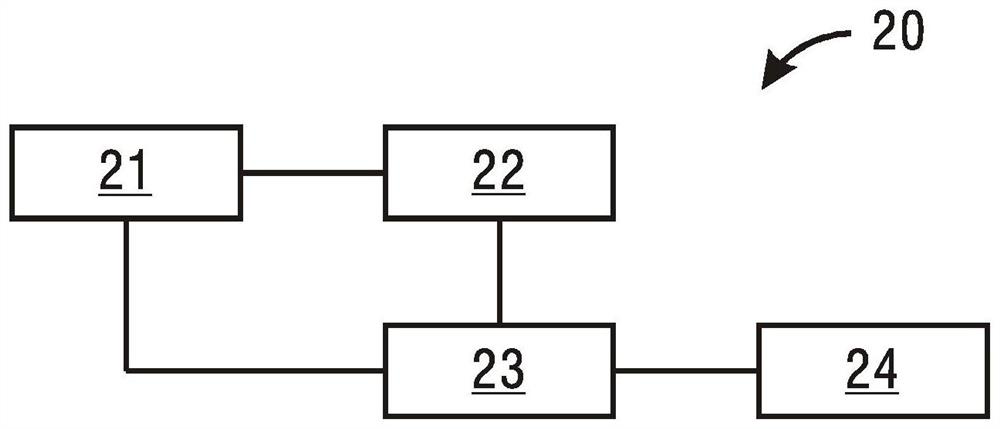

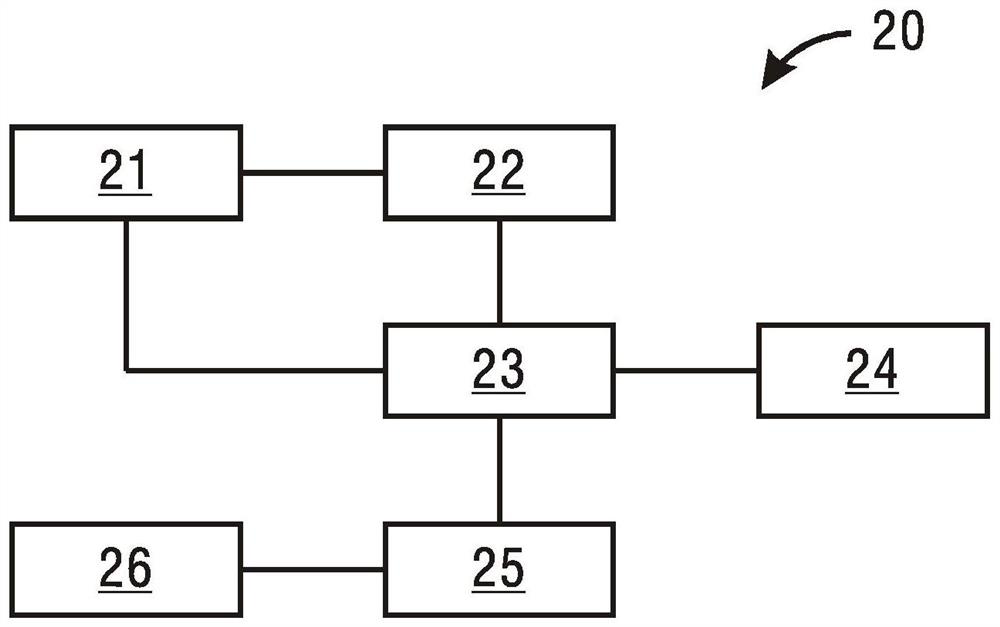

[0083] In the embodiment of the present invention, the automobile manufacturing plant is divided into multiple production areas, so that each production area includes one or mor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com