Brake pad grinding equipment for new energy automobile manufacturing

A technology for new energy vehicles and brake pads, which is applied in the direction of grinding/polishing equipment, manufacturing tools, metal processing equipment, etc., and can solve problems such as inaccurate placement and low grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

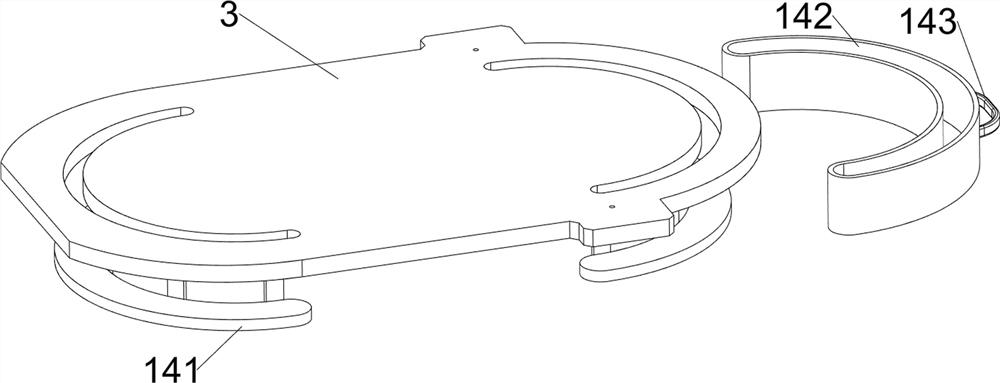

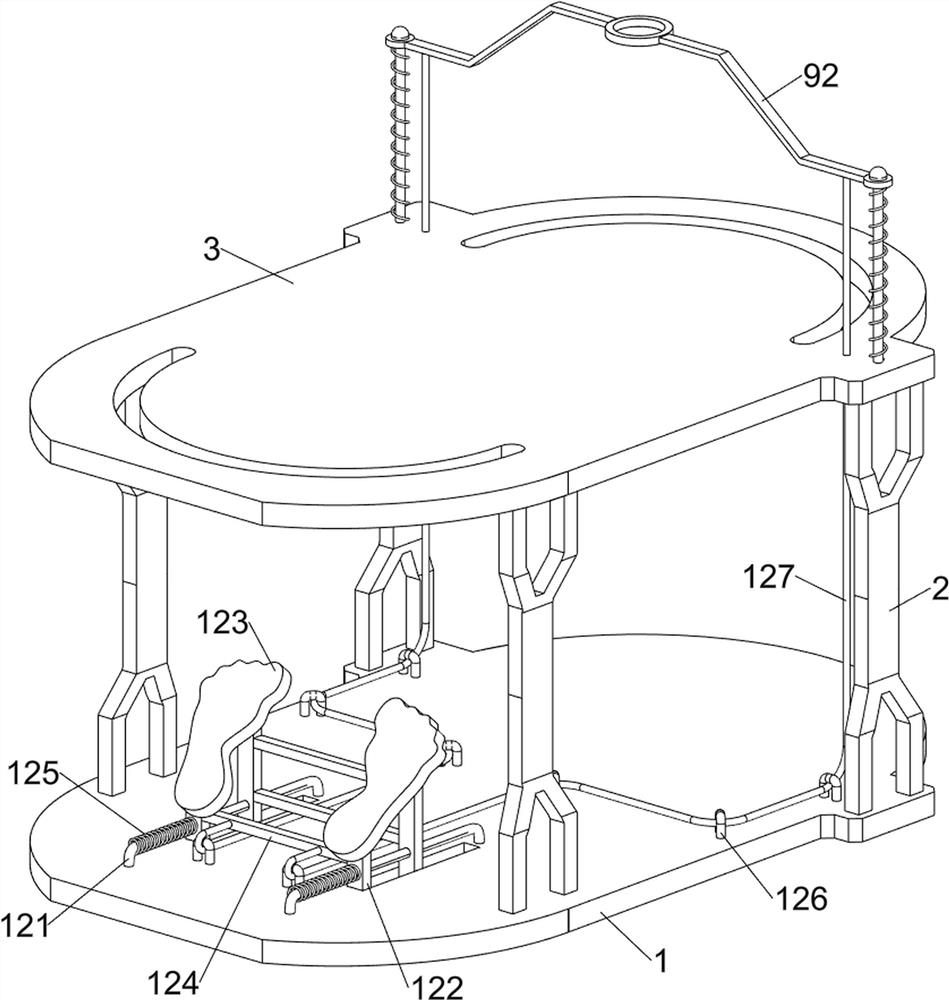

[0044] A new energy vehicle manufacturing brake pad polishing equipment, such as figure 1 As shown, it includes a base plate 1, a pole 2, an operation panel 3, a bracket 4, a motor 5, a spline 6, a shaft sleeve 7, a grinding disc 8, a pressing component 9 and a moving component 10, and the base plate 1 is provided with 4 The pole 2 is connected with the operation panel 3 between the tops of the poles 2, the right side of the top of the operation panel 3 is symmetrically provided with a support 4, the top of the support 4 is connected with a motor 5, and the output shaft of the motor 5 is provided with a spline 6, The spline 6 is slidably provided with a shaft sleeve 7 , the bottom of the shaft sleeve 7 is provided with a grinding disc 8 , the right side of the top of the operating panel 3 is provided with a pressing assembly 9 , and the top of the operating panel 3 is provided with a moving assembly 10 .

[0045] The staff can place the brake pads on the moving assembly 10, an...

Embodiment 2

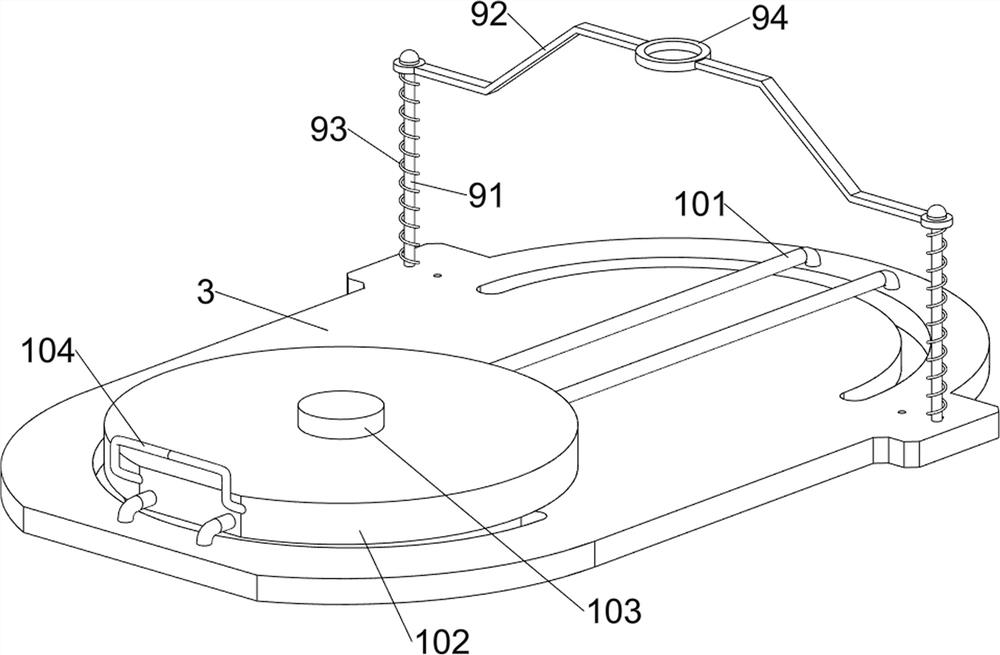

[0047] On the basis of Example 1, such as figure 2 As shown, the pressing assembly 9 includes a guide rod 91, a pressure rod 92, a first spring 93 and an annulus 94, and the right side of the top of the operating panel 3 is symmetrically provided with a guide rod 91, and the guide rod 91 is slidably provided with a pressure rod. 92, a circular ring 94 is connected between the compression rods 92, and the circular ring 94 cooperates with the lower part of the bushing 7, and a first spring 93 is connected between the bottom of the compression rod 92 and the guide rod 91.

[0048] The staff can push the pressure rod 92 to move downward to drive the ring 94 to move downward, thereby driving the shaft sleeve 7 and the grinding disc 8 to move downward for grinding. At this time, the first spring 93 is compressed, and after the grinding is completed, stop pushing the pressure rod 92 , the first spring 93 resets and drives the ring 94 and its upper parts to move upwards and resets th...

Embodiment 3

[0052] On the basis of Example 2, such as Figure 3 to Figure 6 As shown, clamping assembly 11 is also included, and clamping assembly 11 includes special-shaped block 111, wedge bar 112, clip block 113, second spring 114, fixed bar 115 and special-shaped bar 116, and both sides of the front and back sides of placing table 102 top A special-shaped block 111 is provided, and the outside of the special-shaped block 111 is slidingly provided with a wedge-shaped rod 112. The inside of the wedge-shaped rod 112 is provided with a clamping block 113, and two second springs 114 are connected between the outside of the clamping block 113 and the wedge-shaped rod 112. The front and rear sides of the plate 3 are symmetrically provided with fixed rods 115, and between the fixed rods 115 on the same side are provided with special-shaped rods 116, and the special-shaped rods 116 are all matched with the wedge-shaped rods 112 on the same side.

[0053]After placing the brake pads, the placin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com