Anti-oxidation ultrahigh-strength steel plate for hot stamping forming and low-temperature thermoforming process thereof

A technology of hot stamping forming and forming process, which is applied in the field of steel materials, can solve the problems that are not conducive to the actual production of hot stamping forming components, it is difficult to control the temperature accuracy and uniformity of components, and it is difficult to reach 1200MPa, so as to achieve excellent high temperature oxidation resistance , improve high temperature oxidation resistance, reduce the effect of high temperature oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0039] The invention provides an oxidation-resistant ultra-high-strength steel plate for hot stamping forming and a low-temperature hot forming process thereof.

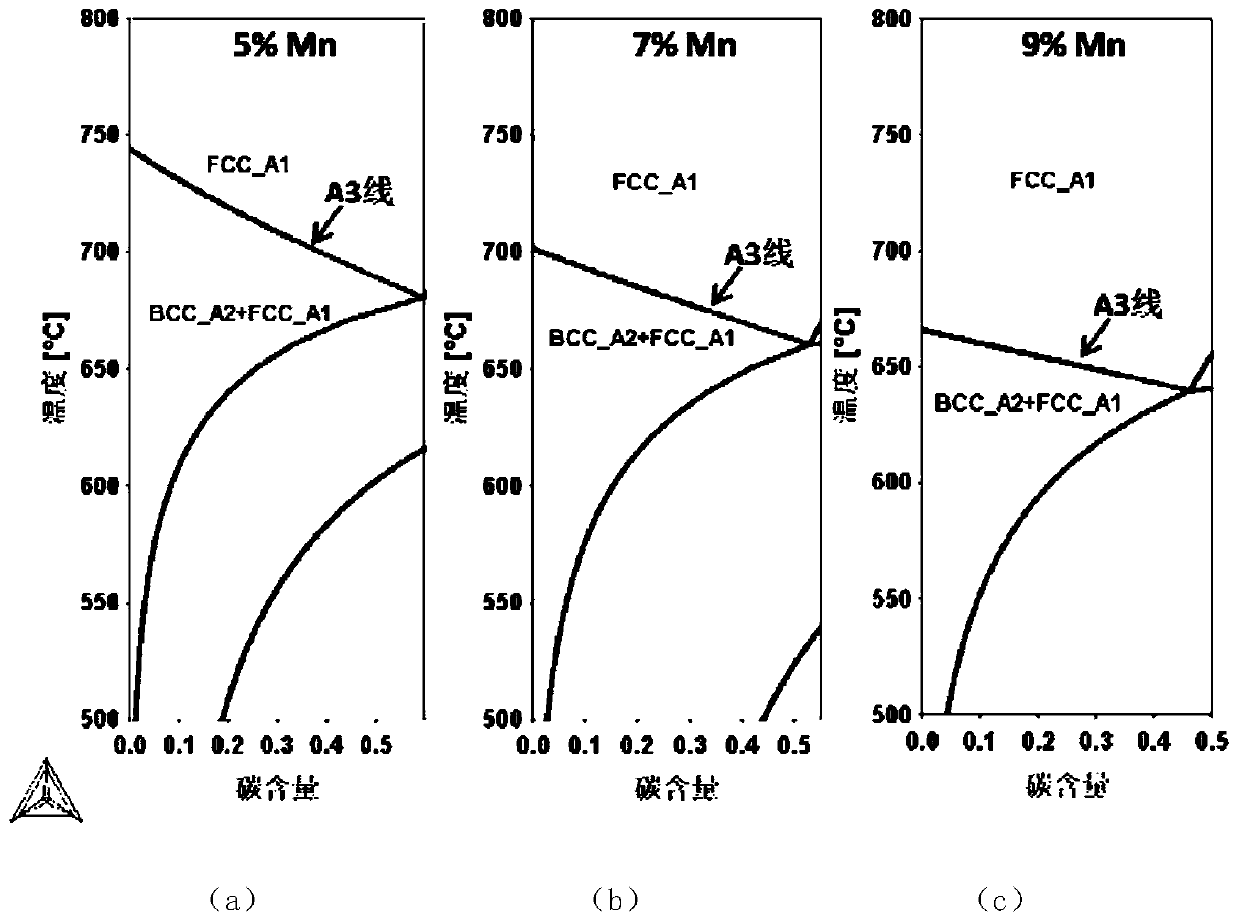

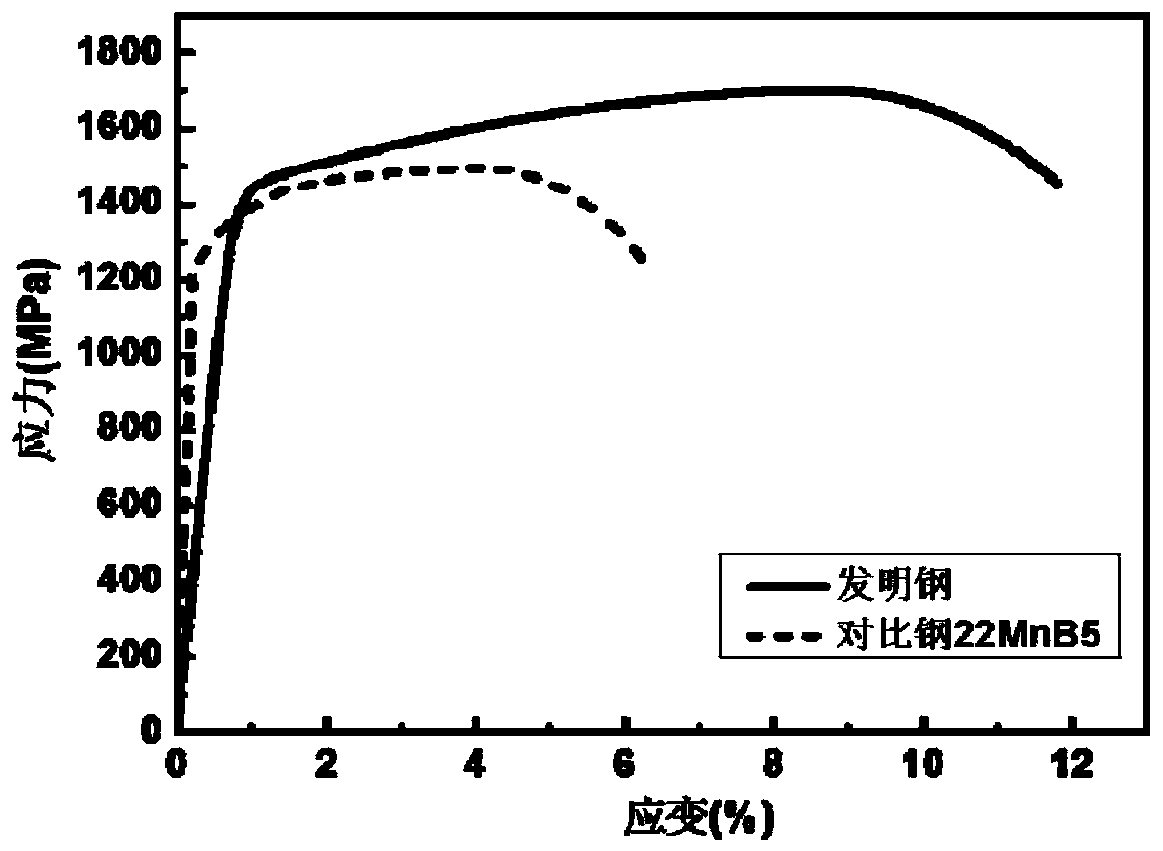

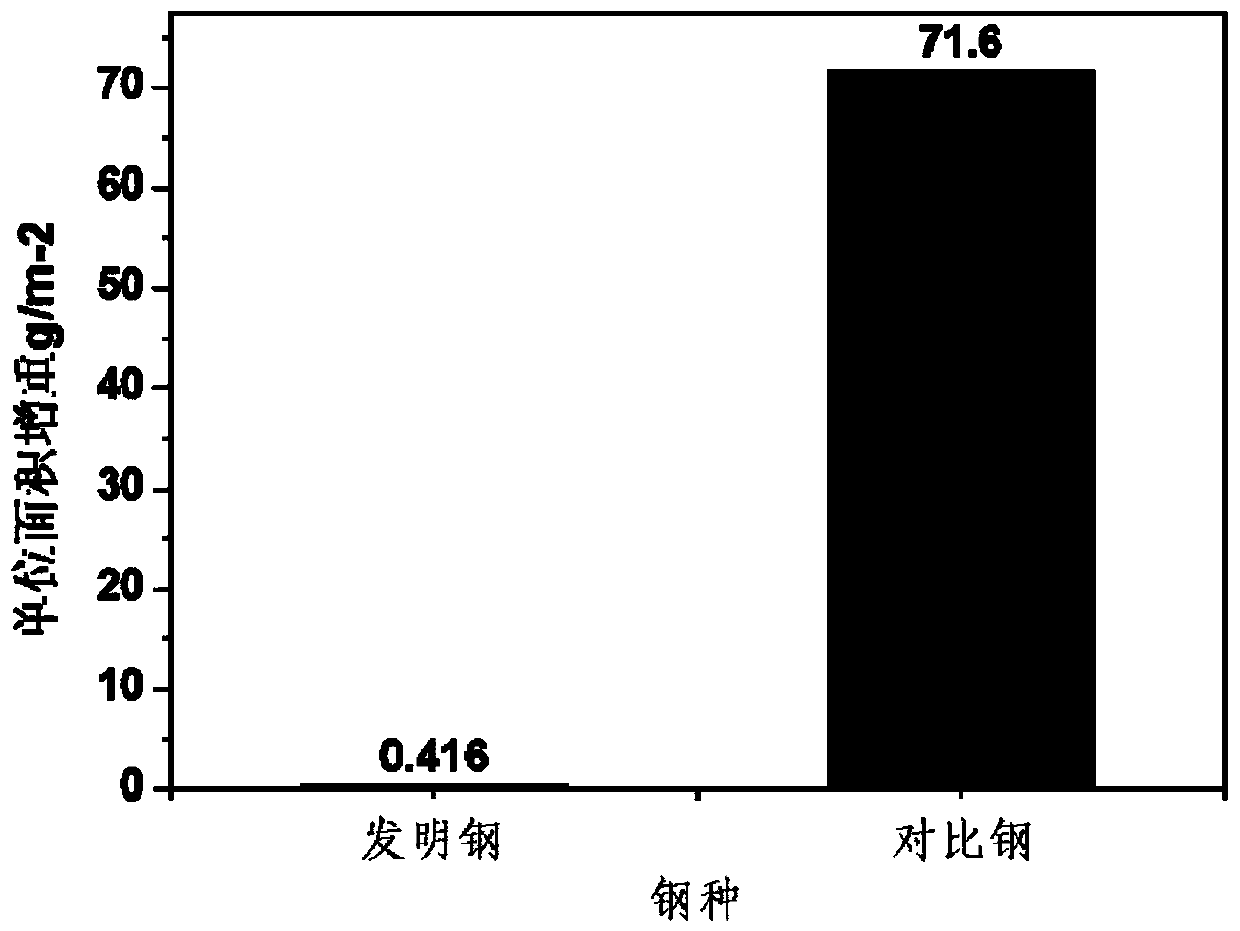

[0040] In terms of weight percentage, the steel plate includes C: 0.2-0.35%, Mn: 6-8%, Cr: 2-5%, Nb+V: 0.05-0.3%, Si: 0.3-0.8%, Al: 0.1-0.8% % and the balance Fe.

[0041] The low temperature hot forming process for preparing the steel plate includes the following steps:

[0042] (1) Heat the steel plate to be processed to 720-770°C and keep it warm for 1-10min;

[0043] (2) transferring the heated steel plate in the step (1) to a mold for stamping to obtain a quenched member of the target geometry;

[0044] (3) The steel plate cooled to room temperature is then heated to 170° C. and kept fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com