Alloy material resistant to corrosion of high-temperature chloride ion molten salt and preparation method of alloy material

A technology of molten salt corrosion and alloy materials, applied in furnace types, manufacturing tools, heat treatment equipment, etc., can solve problems such as the increase in the frequency of accidents, achieve simple production process, improve resistance to chloride ion corrosion performance and safety, inhibit aging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] In this embodiment, a method for preparing an alloy material resistant to high temperature chloride ion molten salt corrosion with excellent hot workability comprises the following steps:

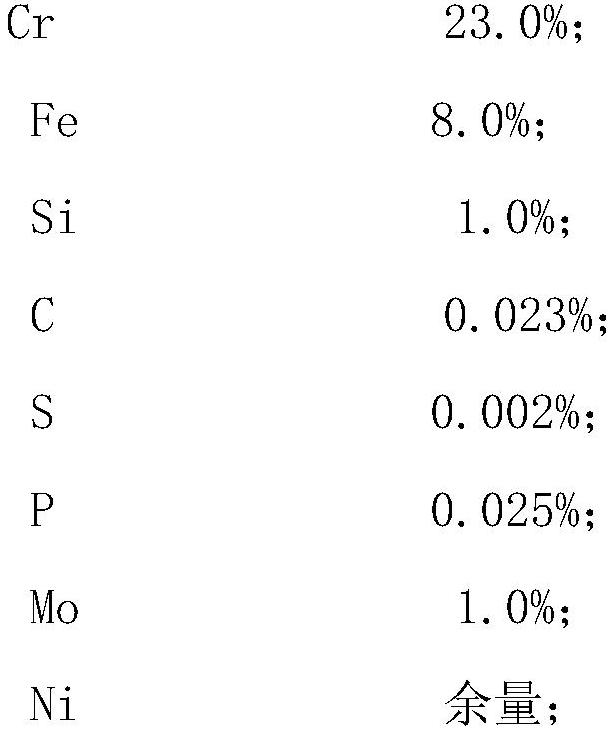

[0023] a. The vacuum induction smelting process is adopted, and when the raw materials are batched, the raw material ingredients used are composed according to the following mass percentage (%) for raw material batching:

[0024]

[0025] Vacuum induction melting is carried out on all raw materials weighed after batching to obtain alloy melt;

[0026] b. The alloy melt prepared in the step a is cast into shape, and the alloy ingot obtained by casting is subjected to hot forging, hot rolling and annealing heat treatment processes in sequence, and finally a high temperature resistant chloride ion melt with excellent hot workability is obtained. Alloy material rod or plate for salt corrosion.

[0027] This example adopts the vacuum induction melting process, melts with comprehensive...

Embodiment 2

[0029] This embodiment is basically the same as Embodiment 1, especially in that:

[0030] In this embodiment, a method for preparing a high-temperature chloride ion molten salt corrosion-resistant method with excellent hot workability includes the following steps:

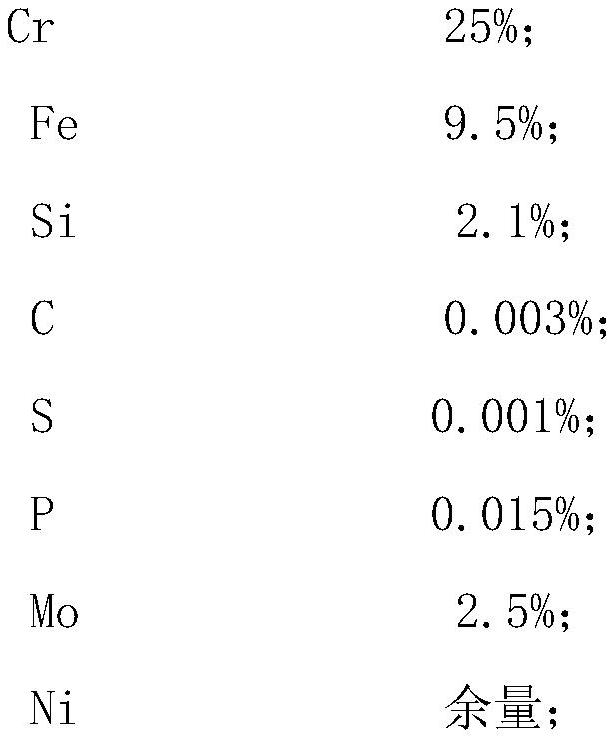

[0031] a. The vacuum induction smelting process is adopted, and when the raw materials are batched, the raw material ingredients used are composed according to the following mass percentage (%) for raw material batching:

[0032]

[0033] Vacuum induction melting is carried out on all raw materials weighed after batching to obtain alloy melt;

[0034] b. This step is the same as in Embodiment 1.

[0035] After experimental testing, the test results show that the tensile fracture strength at room temperature of the high-temperature chloride ion molten salt corrosion-resistant alloy material plate prepared in this embodiment is greater than 620 MPa, and the elongation at break is greater than 45%. The mechanica...

Embodiment 3

[0037] This embodiment is basically the same as the previous embodiment, and the special features are:

[0038] In this embodiment, a method for preparing a nuclear shielding austenitic stainless steel alloy material with excellent hot workability includes the following steps:

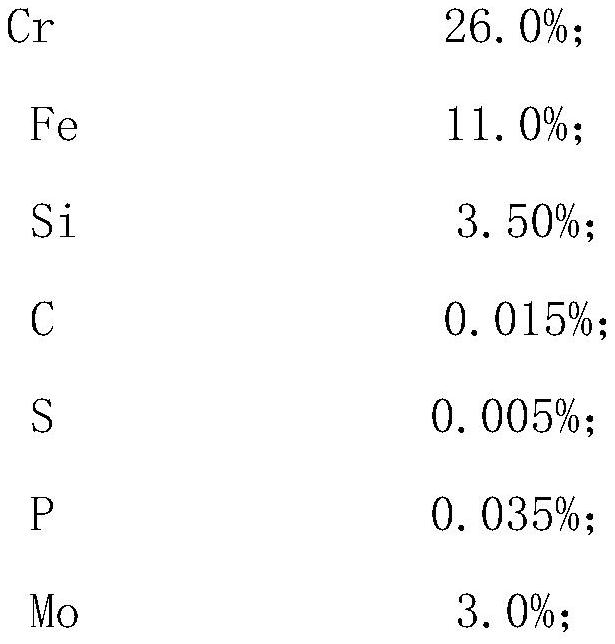

[0039] a. The vacuum induction smelting process is adopted, and when the raw materials are batched, the raw material ingredients used are composed according to the following mass percentage (%) for raw material batching:

[0040]

[0041]

[0042] Vacuum induction melting is carried out on all raw materials weighed after batching to obtain alloy melt;

[0043] b. This step is the same as in Embodiment 1.

[0044]After experimental testing, the test results show that the tensile fracture strength at room temperature of the alloy material with excellent hot workability and corrosion resistance to high temperature chloride ion molten salt prepared in this embodiment is greater than 650 MPa, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength at break | aaaaa | aaaaa |

| tensile strength at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com