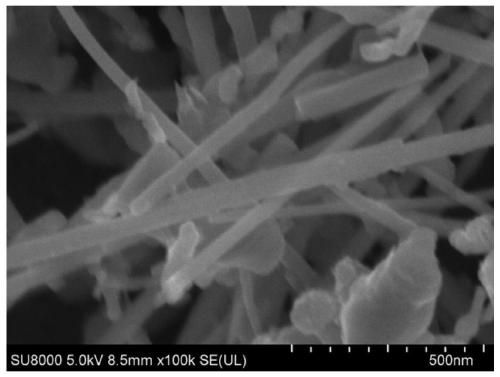

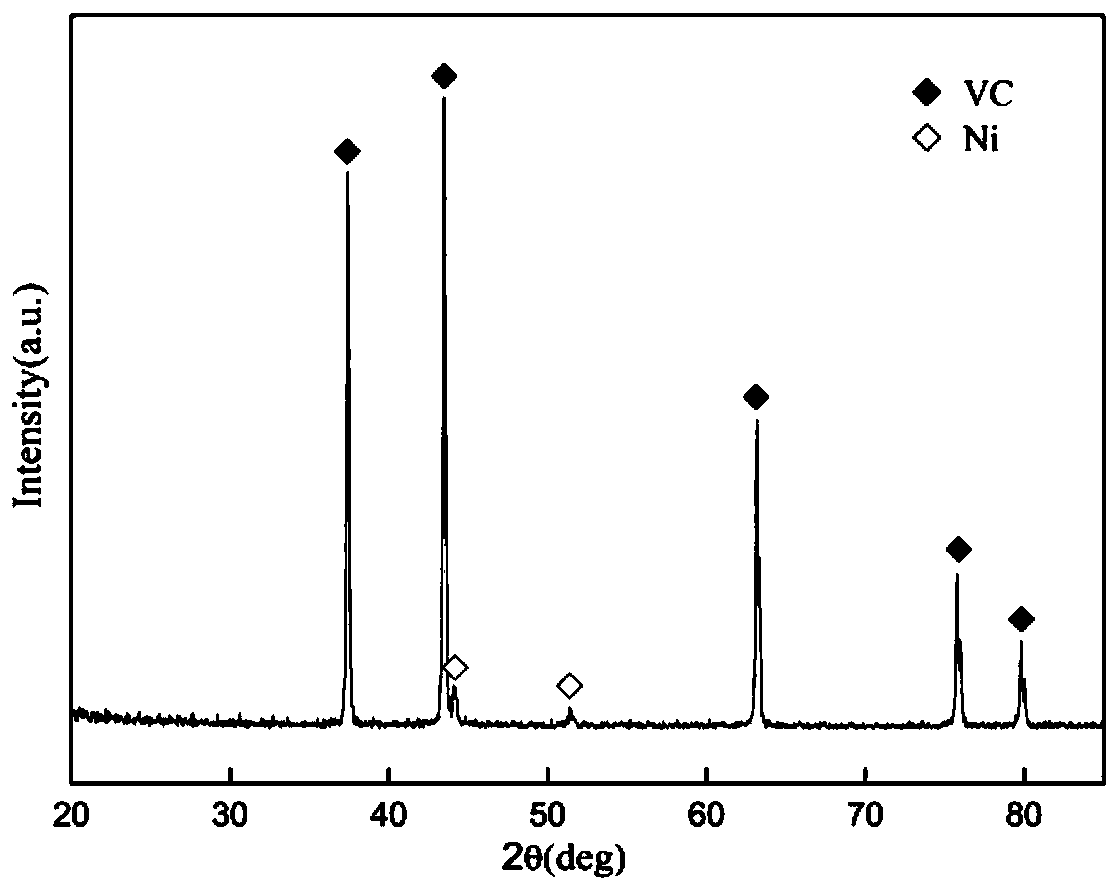

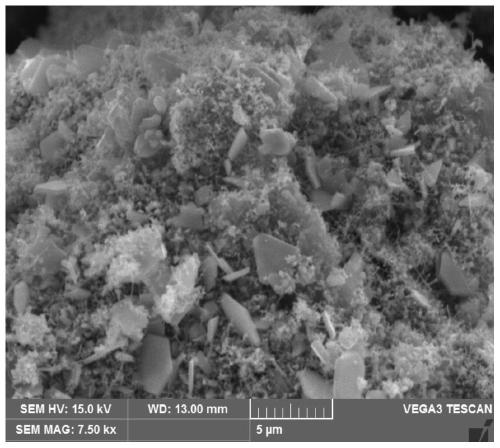

A kind of nano-VC whisker and preparation method thereof

A whisker and nanotechnology, applied in the field of nano-VC whiskers and its preparation, can solve the problems of industrial mass production limitations, whisker yield improvement, unfavorable industrial production, etc., and achieve shortened atomic migration distance and long diameter Large ratio, beneficial to the effect of industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The preparation method of the nano VC whisker of the present embodiment comprises:

[0038] (1) Sodium metavanadate, xylose, potassium fluoride and sodium fluoride are dissolved in deionized water to obtain a precursor solution; wherein, the sodium metavanadate and xylose are according to carbon: the molar ratio of vanadium atoms is The ratio of 3:1 is added, the addition of the potassium fluoride is 100wt% of the theoretical production amount of vanadium carbide, and the addition of the ferric chloride is 25wt% of the theoretical production amount of VC;

[0039] (2) Place the precursor solution in an air blast drying oven, dry it at 75°C, grind it, pass it through a 300-mesh sieve, and take the undersize as the precursor mixture;

[0040] (3) Calcining the precursor mixture in an inert atmosphere at a temperature of 350° C. for 2 hours to obtain a pre-calcined product, which is cooled for later use;

[0041] (4) Precalcining the precalcined product in an inert atmosp...

Embodiment 2

[0044] The preparation method of the nano VC whisker of the present embodiment comprises:

[0045] (1) Ammonium metavanadate, glucose, sodium fluoride, nickel chloride and cobalt chloride (catalyst mass ratio 1:1) are dissolved in deionized water to obtain a precursor solution; wherein, the ammonium metavanadate Glucose is added according to the ratio of carbon: vanadium atom molar ratio is 5: 1, the addition amount of described sodium fluoride is 200wt% of the theoretical production amount of vanadium carbide, the total addition amount of described nickel chloride and cobalt chloride is VC theory 70wt% of the generated amount;

[0046] (2) Place the precursor solution in a blast drying oven, dry it at 85°C, grind it, pass it through a 350-mesh sieve, and take the undersize as the precursor mixture;

[0047] (3) Calcining the precursor mixture in an inert atmosphere at a temperature of 600° C. for 1 h to obtain a pre-calcined product, which is cooled and used for later use; ...

Embodiment 3

[0051] The preparation method of the nano VC whisker of the present embodiment comprises:

[0052] (1) Ammonium metavanadate, xylose, sodium fluoride and nickel chloride are dissolved in deionized water to obtain a precursor solution; wherein, the ammonium metavanadate and xylose are according to carbon: the molar ratio of vanadium atoms is The ratio of 4:1 is added, the addition of the sodium fluoride is 150wt% of the theoretical production amount of vanadium carbide, and the addition of the nickel chloride is 50wt% of the theoretical production amount of VC;

[0053] (2) Place the precursor solution in a blast drying oven, dry it at 80° C., grind it, pass it through a 300-mesh sieve, and take the undersize as the precursor mixture;

[0054] (3) Calcining the precursor mixture in an inert atmosphere at a temperature of 400° C. for 1.5 hours to obtain a pre-calcined product, which is cooled for later use;

[0055] (4) Precalcining the precalcined product in an inert atmospher...

PUM

| Property | Measurement | Unit |

|---|---|---|

| lattice constant | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com