00Cr20Mo16 welding wire and production process thereof

A 00cr20mo16, production process technology, applied in welding media, manufacturing tools, welding equipment, etc., can solve problems such as the inability to meet the needs of pipeline welding, achieve excellent high temperature oxidation resistance and corrosion resistance, sufficient degassing, reduce gas content and Effects of harmful element content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

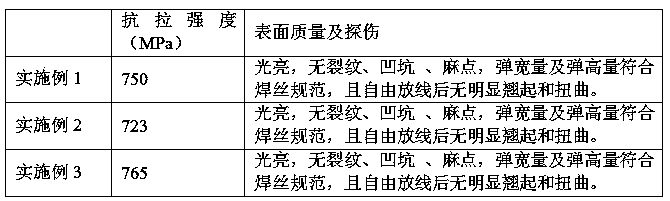

Examples

Embodiment 1

[0044] The element composition and the weight percentage of each component of the welding wire are: C is 0.03%, Si is 0.3%, Mn is 0.6%, P is 0.01%, S is 0.01%, Cr is 19.5%, Mo is 15.2%, Cu is 0.06%, Co is 0.06%, Ti is 0.15%, N is 0.03%, Fe is 2.0%, and the balance is Ni.

Embodiment 2

[0046]Wherein, preferably, the chemical composition of the welding wire and the weight percent content of each component are: C is 0.01%, Si is 0.1%, Mn is 0.9%, P is 0.005%, S is 0.005%, Cr is 20.3%, Mo is 16%, Cu is 0.05%, Co is ≤0.04%, Ni-Mg is 0.15%, Ti is 0.1%, N is 0.02%, Fe is 0.5%, and the balance is Ni.

Embodiment 3

[0048] C is ≤0.02%, Si is 0.2%, Mn is 1.0%, P is 0.002%, S is 0.002%, Cr is 21.0%, Mo is 16.5%, Cu is 0.02%, Co is 0.02%, and Ti is 0.05% , N is ≤0.01%, Fe is ≤1.0%, and the balance is Ni.

[0049] The production technology of the 00Cr20Mo16 welding wire of above-mentioned each embodiment of the present invention all adopts following steps:

[0050] Step (1) Vacuum smelting: the raw materials are distributed according to the design, and put into the vacuum furnace for smelting, and the vacuum furnace is evacuated, and when the vacuum degree is lower than 1Pa, the electric smelting is carried out; in this process, new materials are used for smelting, and the existing regulations are implemented. ; Wherein Al and Ni-Mg in the raw material are used as deoxidation;

[0051] Step (2) Electroslag remelting: use 7:3 slag system after baking, and perform electroslag remelting process to obtain steel ingots;

[0052] Step (3) Forging: Forging the steel ingot into a 40mm×40mm forging ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com