A comprehensive partition heat treatment method of c and mn in low carbon c-mn-si steel with trip effect

A heat treatment method, c-mn-si technology, applied in Mn comprehensive distribution heat treatment, low-carbon C-Mn-Si series steel C, low-carbon steel heat treatment field, can solve the problem of reducing austenite stability, reducing horse It can improve the stability, lower the heating temperature and lower the austenitization temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Clean the cold-rolled steel plate with the composition of 0.12C-1.5Mn-1.1Si, remove rust and oil, and then air-dry to make the surface smooth. To avoid uneven heating during heat treatment.

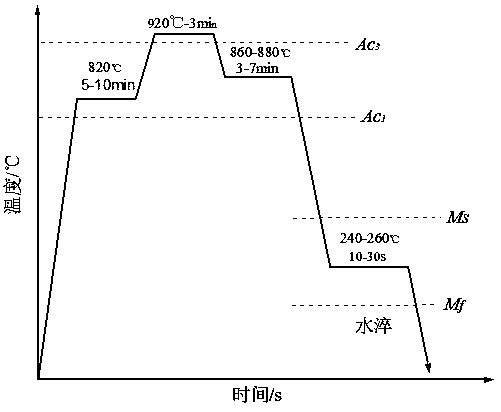

[0026] (1) The first Mn distribution: the pretreated low-carbon C-Mn-Si steel was heated to 820°C in the two-phase region and kept for 5 minutes.

[0027] (2) Complete austenitization: heat to 920°C in the austenite zone and keep it warm for 3 minutes to make it completely austenitized.

[0028] (3) The second Mn distribution: lower the temperature of the test steel to 870°C, keep it warm for 5 minutes, and perform the second Mn distribution.

[0029] (4) Carbon partitioning: Quenching to 260°C quickly after the heat preservation is over, controlling the partitioning time to 20s, and finally water quenching to room temperature.

[0030] figure 2 SEM image of low carbon C-Mn-Si steel obtained by heat treatment process. The microstructure is mainly composed of martensite, ferrit...

Embodiment 2

[0033] Clean the cold-rolled steel plate with the composition of 0.12C-1.5Mn-1.1Si, remove rust and oil, and then air-dry to make the surface smooth. To avoid uneven heating during heat treatment.

[0034] (1) The first Mn distribution: the pretreated low-carbon C-Mn-Si steel was heated to 820°C in the two-phase region and kept for 7 minutes.

[0035] (2) Complete austenitization: heat to 920°C in the austenite zone and keep it warm for 3 minutes to make it completely austenitized.

[0036] (3) The second Mn distribution: lower the temperature of the test steel to 870°C, keep it warm for 7 minutes, and carry out the second Mn distribution.

[0037] (4) Carbon partitioning: Quenching to 240°C quickly after the heat preservation is over, controlling the partitioning time to 30s, and finally water quenching to room temperature.

[0038] According to backscattered and electron probe images, the raised part is martensite, and the depressed part is ferrite. Martensite is transfor...

Embodiment 3

[0041] Clean the cold-rolled steel plate with the composition of 0.12C-1.5Mn-1.1Si, remove rust and oil, and then air-dry to make the surface smooth. To avoid uneven heating during heat treatment.

[0042] (1) The first Mn distribution: the pretreated low-carbon C-Mn-Si steel was heated to 820°C in the two-phase region and kept for 7 minutes.

[0043] (2) Complete austenitization: heat to 920°C in the austenite zone and keep it warm for 3 minutes to make it completely austenitized.

[0044] (3) The second Mn distribution: lower the temperature of the test steel to 870°C, keep it warm for 5 minutes, and perform the second Mn distribution.

[0045] (4) Carbon partitioning: Quenching to 260°C quickly after the heat preservation is over, controlling the partitioning time to 20s, and finally water quenching to room temperature.

[0046] After testing, its tensile strength is 940MPa, its elongation after fracture is 15.6%, and its strong-plastic product reaches 14700MPa·%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com