Preparation method of vertical texture colorful board as well as colorful board manufactured by using preparation method

A color plate, texture technology, applied in the direction of pretreatment surface, device for coating liquid on the surface, coating, etc., can solve the problems of single appearance effect, poor surface scratch resistance, etc., to achieve stable appearance performance, scratch resistance The effect of improving the damage ability and increasing the anti-scratch ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

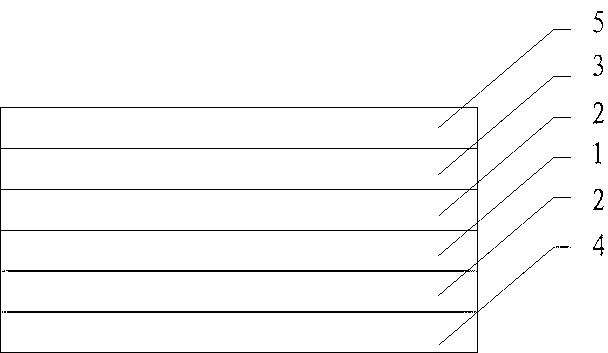

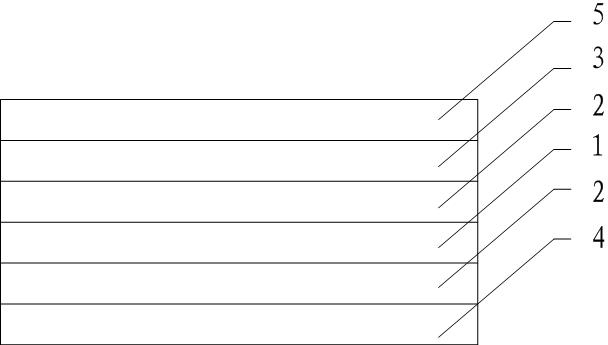

[0054] Such as figure 1 As shown, a vertical texture color plate includes a substrate 1, on the front of the substrate 1, from bottom to top, there are chemical treatment layer 2, white primer layer 3, topcoat layer 5, on the back of the substrate 1, from top to bottom From bottom to bottom are chemical treatment layer 2 and back paint layer 4, and the top paint layer 5 is a crystal red vertical pattern top paint, which adopts a polyester resin system.

[0055] The topcoat layer adopts a polyester resin system, and the formula and parts by weight of the polyester resin system are as follows: 60 parts of polyester resin; 15 parts of amino resin; 8 parts of acid catalyst; 8 parts of silicon-free polymer; 9 servings.

[0056] The color-coated steel plate has high surface hardness, stable scratch resistance and scratch resistance.

[0057] The substrate 1 is made of cold-rolled sheet, hot-dip galvanized sheet, electro-galvanized sheet, zinc-iron alloy sheet or aluminum alloy she...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com