Autoclaved aerated concrete brick prepared by utilizing pulverized fuel ash and preparation method thereof

A technology of autoclaved gas filling and fly ash, which is applied in the field of building materials, can solve the problems of large environmental pollution, different raw material ratios, and increased specific gravity, and achieve obvious improvement effects, reduce environmental pollution, and increase stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] A kind of preparation method of the aerated concrete brickwork that utilizes the waste fly ash after the power plant incinerates coal of the present invention is:

[0024] 1. Raw material preparation: materials by weight are 65%-68% of fly ash, 17%-23% of lime, 6%-10% of cement, 2%-4% of desulfurized gypsum powder, and 1%-1.5% of water-soluble aluminum powder %, fatty acid soap 0.3%-0.5%, acacia powder 0.3%-0.5%.

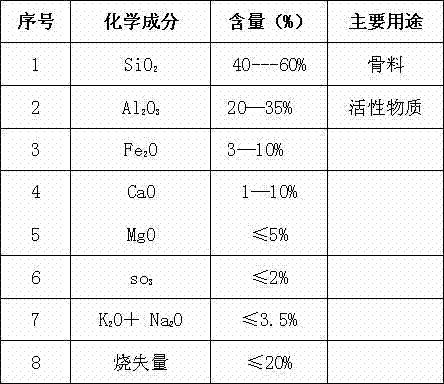

[0025] Among them, fly ash:

[0026] Fly ash is a spherical granular vitreous body, the main mineral is silica-alumina vitreous body, the content is 70%, there are also crystalline minerals mullite and quartz, a small amount of calcium carbonate, hematite and magnetite, etc., and some of them have different shapes. Regular coke particles and semi-coke particles have good activity, the average fineness is ≤15% according to the standard of 0.08㎜ square hole sieve, the loss on ignition ≤5.0%, sio 2 ≥45%, so 3 ≤1.0.

[0027] Fly ash is mixed with desulfurized...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com