Method for treating manganese-series phosphorized waste water

A treatment method and technology for wastewater, applied in chemical instruments and methods, flotation water/sewage treatment, adsorption water/sewage treatment, etc. Water and water outlet structure, no operation and maintenance costs, the effect of improving buffer capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

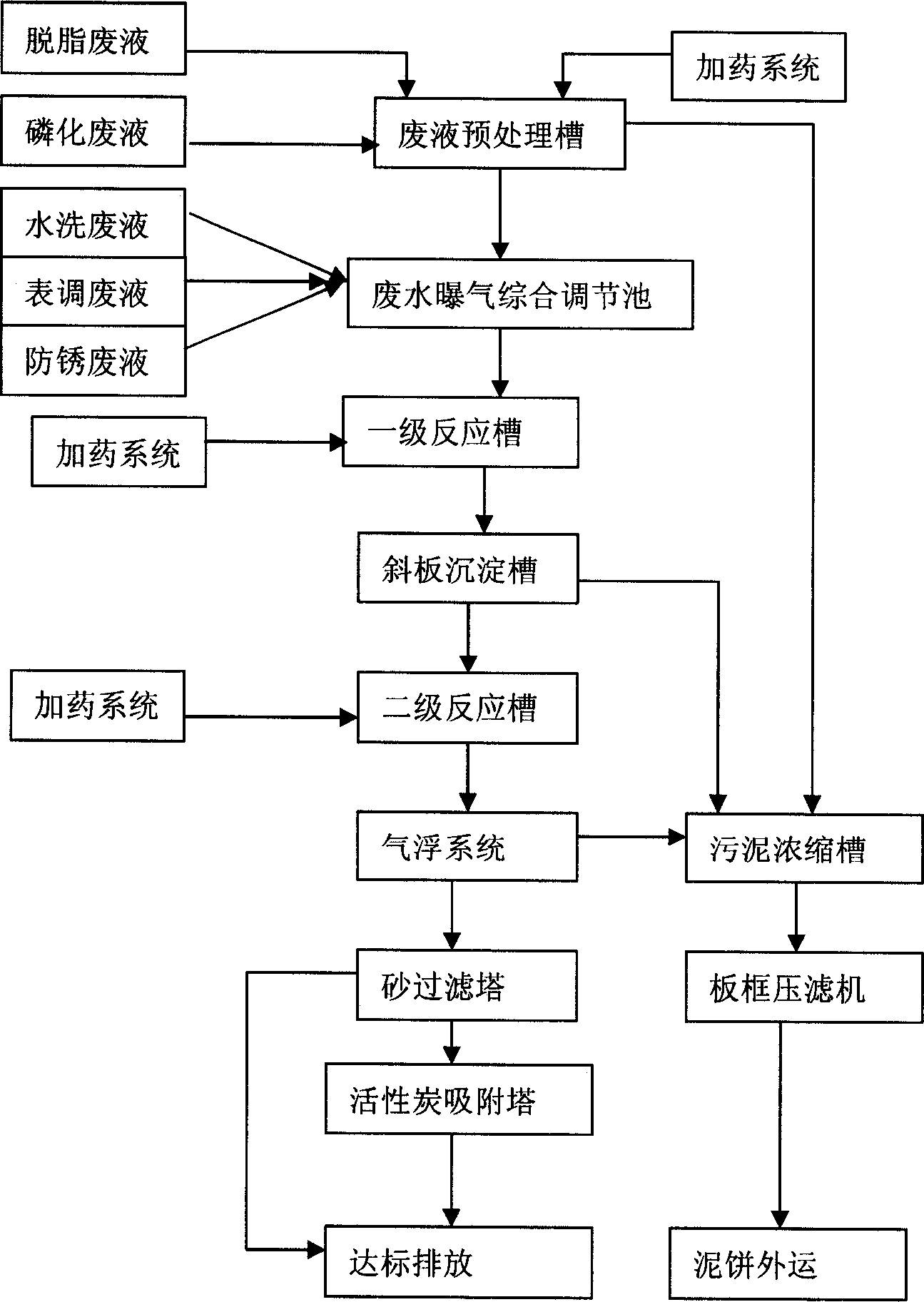

Image

Examples

Embodiment 1

[0054] The manganese-based phosphating wastewater (mainly overflowing washing wastewater) usually produced by the phosphating section is taken, and the influent water quality is detected as:

[0055] pH value

(mg / L)

Oil (mg / L)

Cod

COD (mg / L)

(mg / L)

Manganese ions Mn 2+

(mg / L)

6.8

186

20

120

155

28.4

[0056] The wastewater directly enters the integrated wastewater continuous treatment system: the wastewater flow rate is 3m 3 / h, pumped into the first-stage reaction tank from the aeration comprehensive adjustment tank, the first-stage reaction tank uses an automatic pH meter to control the pH value of 10-11, and first adds Ca(OH) 2 , and then add coagulant ferrous sulfate and coagulant PAM, after the reaction, the precipitate enters the inclined plate sedimentation tank for solid-liquid separation, and the liquid enters the sec...

Embodiment 2

[0060] Take the manganese-based phosphating waste water and the overflow washing waste water produced when the surface adjustment waste liquid and the anti-rust waste liquid of the phosphating chemical section are poured at the same time, and the respective influent water quality is detected as follows:

[0061] water sample

pH value

(mg / L)

Oil

(mg / L)

Cod

COD (mg / L)

(mg / L)

manganese ion

(mg / L)

Surface waste liquid

6.2

5.3

300

7.23

6.59

Anti-rust waste liquid

8.7

2.1

24

13.3

0.82

washing wastewater

6.9

132

35

142

112

47.2

[0062] The waste liquid from surface adjustment tank and anti-rust tank can be directly discharged into the wastewater aeration comprehensive adjustment tank without pretreatment, mixed with the overflow washing wastewater and then entered...

Embodiment 3

[0066] Take the high-concentration manganese-based phosphating wastewater produced when the degreasing waste liquid and phosphating waste liquid of the phosphating chemical section are poured into the tank at the same time, and the respective water quality and the water quality after mixing are detected as follows:

[0067]

pH value

(mg / L)

Oil (mg / L)

COD (mg / L)

PO 4 3- (mg / L)

mn 2+ (mg / L)

Degreasing waste water

11.6

896

1000

2460

4.03

Phosphating tank waste water

3

526

262

288

232

Mixed High Concentration Wastewater

500~1000

310~466

690~1380

200~300

100~200

[0068] The degreasing tank liquid and the phosphating tank liquid waste water are first mixed and then subjected to sulfuric acid acidification and demulsification treatme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com