Production method of environment-friendly and safe furnace carbon black and carbon black product

A production method, furnace carbon black technology, applied in the direction of fibrous fillers, etc., can solve the problems of complex raw material oil composition, unstable quality, adsorption, etc., and achieve the effects of being conducive to dispersed use, safe and reliable production process, and safe and reliable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

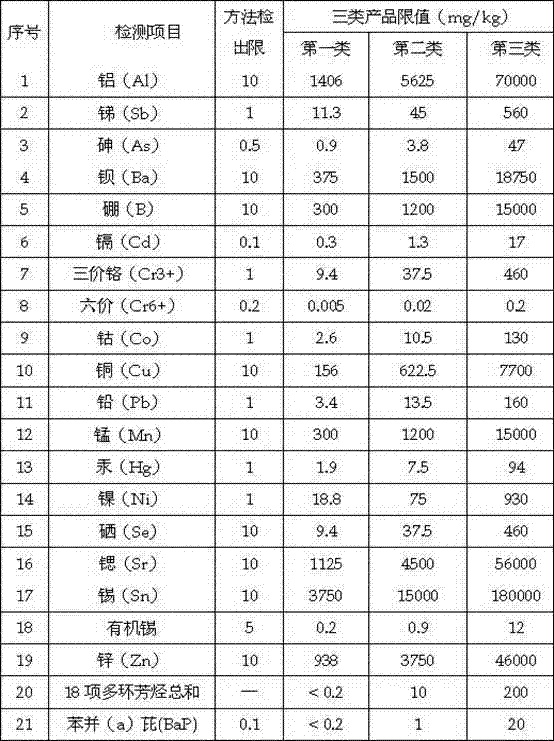

[0045] Determination of environmental safety standards:

[0046] Taking EN71-3 and ZEK01.4-8 as the reference object, the migration amount of 19 harmful elements and the content of 18 harmful polycyclic aromatic hydrocarbons are classified and restricted, and the environmental protection and safety furnace carbon black is divided into three categories Among them, the first category has the most stringent requirements, the second category is the second, and the third category is the third. The environmental protection and safety indicators for setting environmental protection and safety furnace carbon black are shown in Table 1:

[0047] Table 1 List of environmental protection and safety indicators of safe furnace carbon black

[0048]

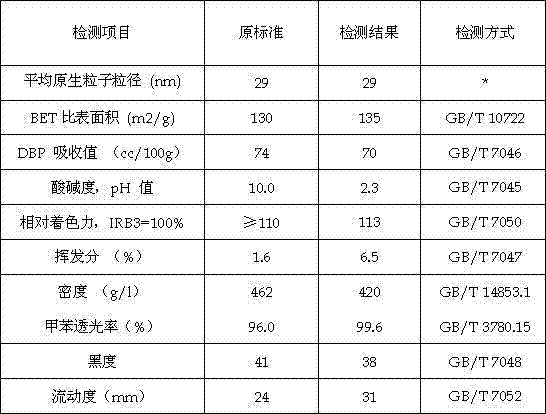

[0049] Product selection:

[0050] Table 2 Embodiment 1 Pigment carbon black technical index

[0051]

[0052] Determination of raw materials:

[0053] The anthracene oil processed by the distillat...

Embodiment 2

[0077] Determination of environmental safety standards:

[0078] Same as Table 1.

[0079] Product selection:

[0080] Using traditional furnace carbon black production equipment and technology, the properties of the products to be produced are shown in Table 5:

[0081] Table 5 Example two pigment carbon black technical index

[0082]

[0083] Determination of raw materials:

[0084] The selection scheme of raw material is the same as example one.

[0085] Production steps:

[0086] Step 1, after the stock oil is preheated, it is sprayed into the furnace method carbon black reaction furnace from the throat section, and the reaction furnace stays in 14 sections, each with a length of 1600 millimeters;

[0087] Step 2, the carbon black flue gas collects the carbon black wherein through the main bag filter;

[0088] Step 3: After the carbon black is pulverized by the micron pulverizer, it is sent to the collection cyclone separator and exhaust ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com