Halogen-free flame retardant glass fiber reinforced nylon as well as preparation method and application thereof

A technology of nylon and glass fiber, which is applied in the field of preparation of halogen-free flame retardant glass fiber reinforced nylon, can solve the problem of undisclosed flame retardant precipitation and other problems, and achieve good mechanical properties, good flame retardant performance, and resistance to flame retardant migration good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

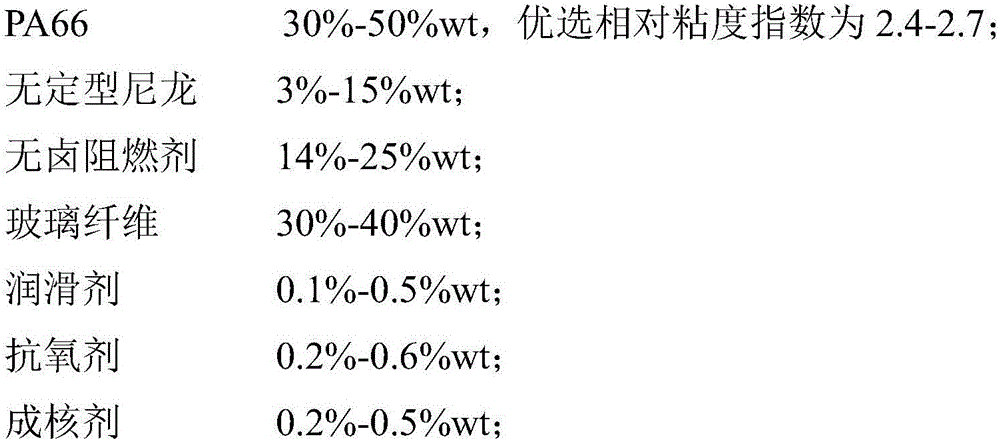

Method used

Image

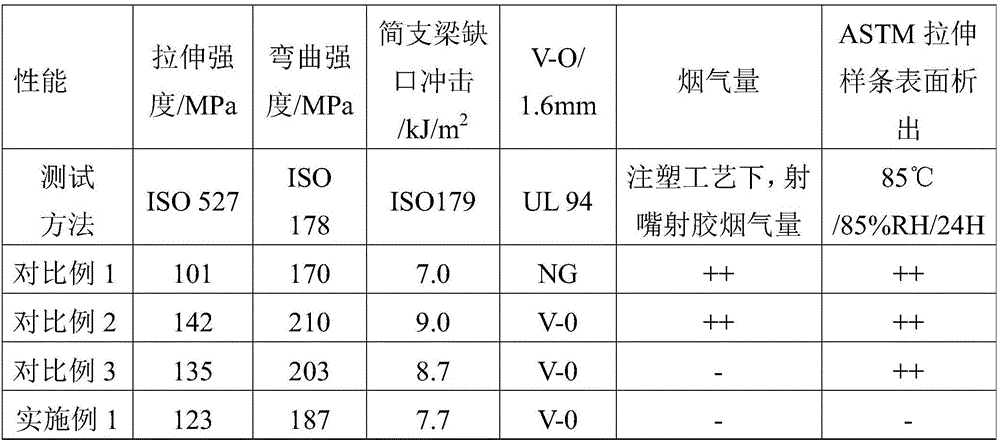

Examples

Embodiment Construction

[0023] Below in conjunction with embodiment, the present invention will be further described:

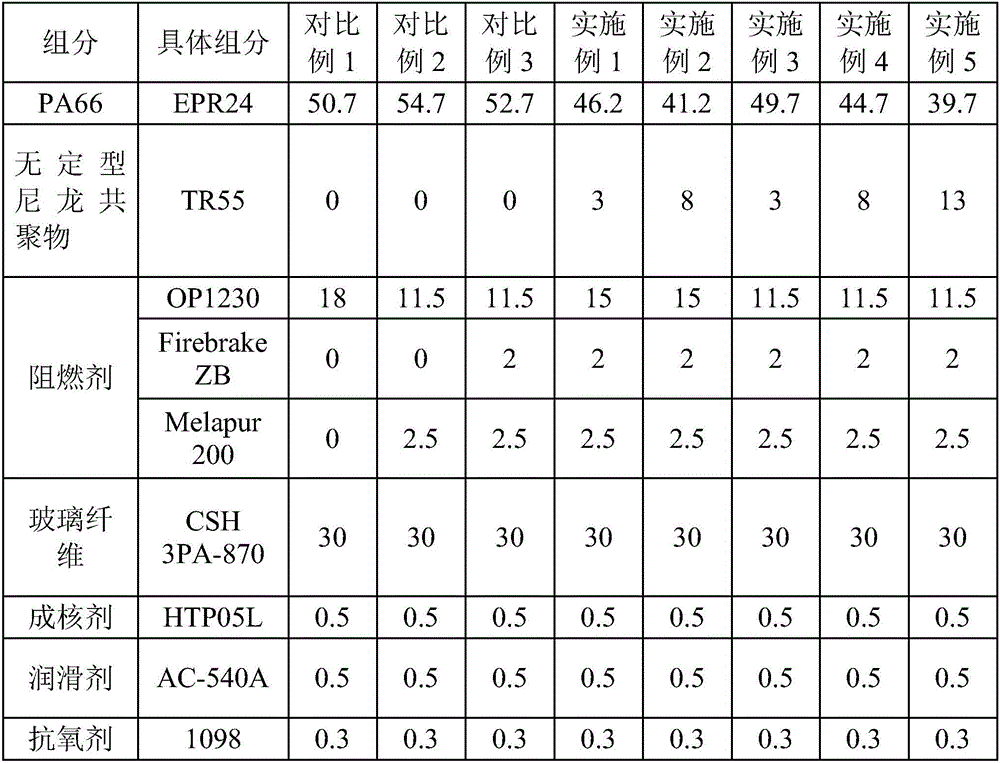

[0024] Raw materials: PA66ERP24 Pingdingshan Shenma; amorphous nylon copolymer Grilamid TR55 Switzerland EMS; diethyl aluminum hypophosphite OP1230 Clariant, MPP Melapur 200 BASF; Zinc Borate Firebrake ZB U.S.Borax Inc.; Glass Fiber CSH 3PA-870 NITTOBO; Lubricant AC-540A Honeywell, Antioxidant 1098BASF; nucleating agent HTP05L Italy IMIFABI.

[0025] First dry the nylon resin at 90°C, add it into the high-speed mixer after 2 hours to 4 hours, then add the compound flame retardant (diethyl aluminum hypophosphite, zinc borate and MPP), glass fiber, lubricant , antioxidant, and nucleating agent are added to a high-speed mixer and mixed for 5 minutes. The mixer adopts medium and low speed mixing, the rotating speed of the mixer is 150rpm, and the gap between the stirring blade and the barrel wall is less than 0.5cm, and the mixture is evenly mixed in the mixer to obtain For the mixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com