A kind of attapulgite/silicon dioxide composite powder and its preparation method

A technology of attapulgite and silicon dioxide, applied in chemical instruments and methods, silicon compounds, alkali metal compounds, etc., can solve the problems of high production cost and cumbersome process, increase mesopore content, reduce manufacturing cost, good The effect of adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

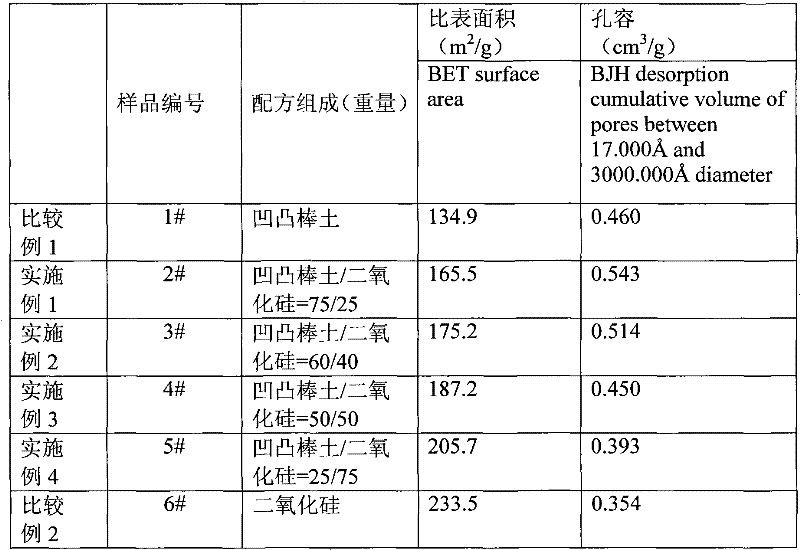

Examples

Embodiment 1

[0028] 1000 grams of attapulgite (produced by Mingmei Mineral Co., Ltd., Anhui Province) is mixed with 19000 milliliters of water at a concentration of 5 wt%, dispersed through a high-shear disperser (produced by FLUKO, model FA25) and placed for more than one week, and then passed through high Dispersion with a shear disperser yields a fully exfoliated suspension. Get 1050 grams and 70 grams of silica sol with the suspension of dispersed attapulgite (Qingdao chemical plant production, trade mark ZA-25, SiO 2 Concentration 25wt%, particle size about 10-20nm, pH value about 7) mixed according to the ratio of 75:25 of their respective dry weights, and then 280 ml of water was added to the mixed solution. At this time, the solid content in the whole mixed solution was 5wt%. , with a laboratory high-shear dispersing emulsifier to stir for 30 minutes at 10,000 rpm, spray in the spray drying test device (QP-3X model, produced by Beijing Beihuayan Petrochemical Design Institute), and...

Embodiment 2

[0030] Mix 1,000 grams of silicon dioxide powder (Shenyang Chemical Co., Ltd., particle size range of 10 to 30 nm) with 19,000 milliliters of water at a concentration of 5 wt%, and disperse through a high-shear disperser (same as Example 1) to obtain a stable suspension liquid. Get prepared attapulgite suspension (same as Example 1) 840 grams and 560 grams of silicon dioxide suspension obtained through dispersion and mix by the 60 / 40 proportioning of respective dry weight, carry out by the same condition as Example 1 After shear dispersion and spray drying, the 3# composite powder with attapulgite and silica ratio of 60 / 40 was obtained.

Embodiment 3

[0032] 700 grams of prepared attapulgite suspension (same as Example 1) and 140 grams of silica sol (same as Example 1) are mixed according to the 50 / 50 proportioning ratio of their respective dry weights, and 560 milliliters of water are added to adjust the mixed liquid-solid content 5 wt%, the rest of the treatment method and operating conditions are the same as in Example 1, and the 4# composite powder with the ratio of attapulgite and silicon dioxide of 50 / 50 is obtained by spray drying.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com