A kind of low-alkali activation preparation method and application of pitch-based activated carbon

An activated carbon and pitch-based technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of short service life of equipment, low conductivity of products, uneven quality, etc., to prolong service life and save alkali consumption , Improve the effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

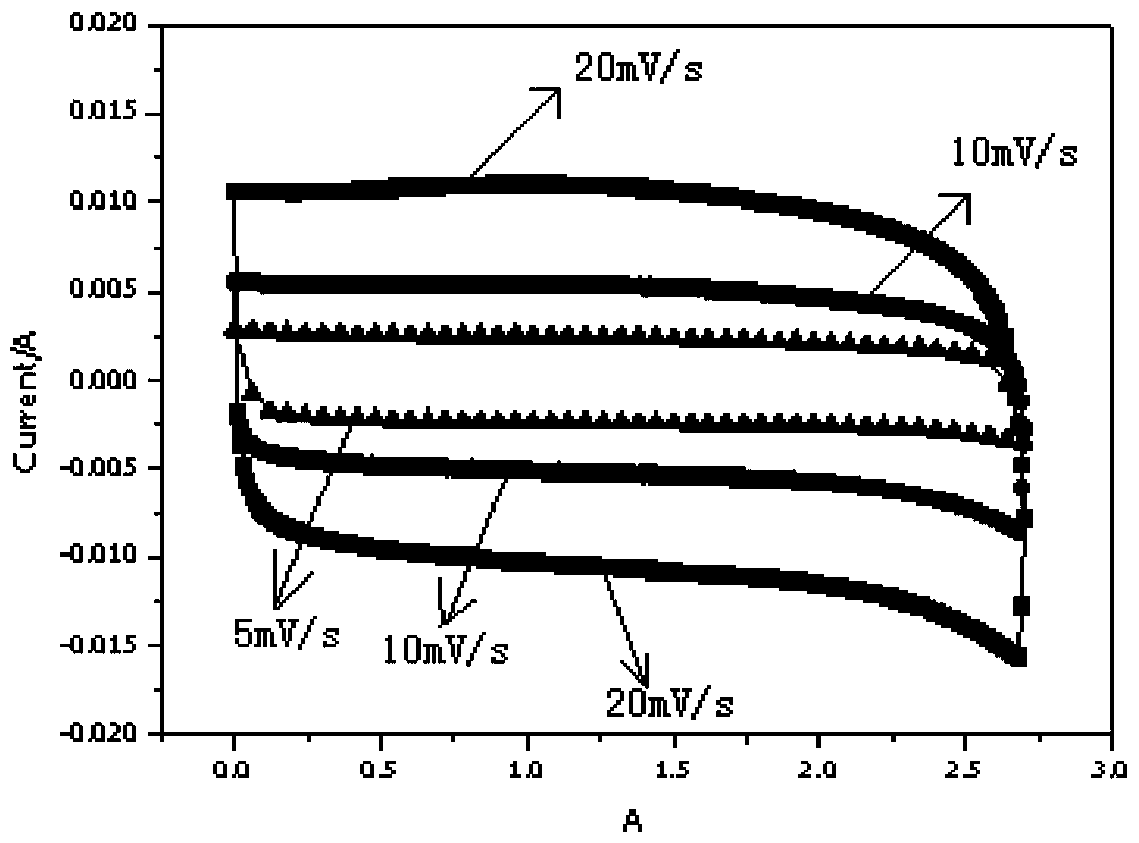

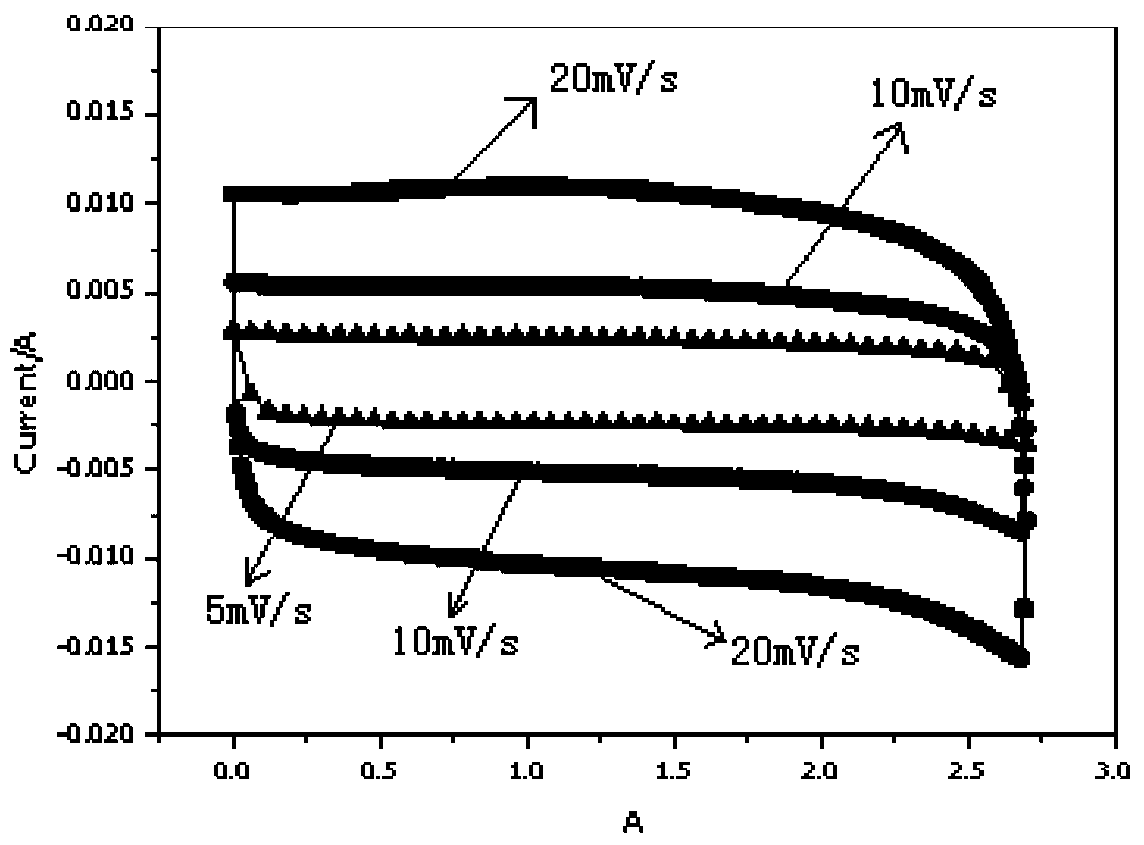

Image

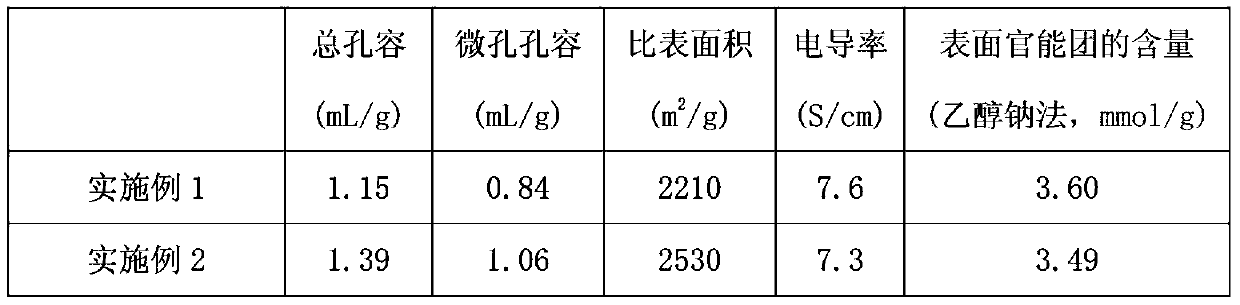

Examples

Embodiment 1

[0043] The low-alkali activation preparation method of pitch-based activated carbon described in this embodiment includes:

[0044] Coking step: place modified pitch with a sulfur content of less than 1wt% and a carbon content greater than 90wt% (its quality standard conforms to the provisions of YB / T 5194-2003) in a coking furnace, under nitrogen protection, at a rate of 1.5°C / min Speed up to 480°C, coking for 9 hours to obtain green coke;

[0045] Mixing step: pulverizing the raw coke, screening the raw coke powder with a particle size of 350-400 mesh; mixing the green coke powder and solid potassium hydroxide evenly according to the mass ratio of 1:1.7, and grinding to form a mixed powder;

[0046] Pre-activation step: put the mixed powder in the activation furnace, stir continuously at a speed of 30rpm, and under the protection of nitrogen, raise the temperature to 250°C at a speed of 5°C / min, keep it warm for 30min, and then raise the temperature to 350°C, keep warm fo...

Embodiment 2

[0051] The low-alkali activation preparation method of pitch-based activated carbon described in this embodiment includes:

[0052] Coking step: putting coal tar pitch with a sulfur content of less than 1wt% and a carbon content of more than 90wt% in a coking furnace, under nitrogen protection, heating up to 450°C at a rate of 10°C / min, and coking for 10 hours to obtain green coke;

[0053] Mixing step: crushing the raw coke, screening the raw coke powder with a particle size of 300-500 mesh; mixing the raw coke powder and solid potassium hydroxide evenly according to the mass ratio of 1:2, and grinding to form a mixed powder;

[0054] Pre-activation step: put the mixed powder in the activation furnace, stir continuously at a speed of 50rpm, and under the protection of nitrogen, raise the temperature to 300°C at a speed of 0.5°C / min, keep it warm for 30min, and then raise the temperature to 400°C, keep warm for 100min, then cool naturally to get the preactivated product;

[0...

Embodiment 3

[0059] The low-alkali activation preparation method of pitch-based activated carbon described in this embodiment includes:

[0060] Coking step: put petroleum pitch with a sulfur content of less than 1wt% and a carbon content of more than 90wt% in a coking furnace, raise the temperature to 460°C at a rate of 0.5°C / min under the protection of argon, and perform coking treatment for 15 hours to obtain raw coke;

[0061] Mixing step: pulverize the raw coke, screen out the raw coke powder with a particle size of 450-500 mesh; mix the raw coke powder and solid sodium hydroxide evenly according to the mass ratio of 1:1, and grind to form a mixed powder;

[0062] Pre-activation step: put the mixed powder in the activation furnace, stir continuously at a speed of 100rpm, and under the protection of argon, raise the temperature to 350°C at a speed of 10°C / min, keep it warm for 80min, and then heat it at 5°C / min The temperature was raised to 500°C at a high speed, kept at a temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com