A kind of network polymer material for negative electrode of sodium ion battery, its preparation method and sodium ion battery

A technology of polymer materials and sodium-ion batteries, applied in battery electrodes, negative electrodes, secondary batteries, etc., can solve the difficulty of meeting the commercialization requirements of sodium-ion batteries, the capacity of hard carbon materials is not high, and the thermal stability needs to be improved and other problems, to achieve good industrial prospects, the overall structure is beneficial, and the effect of enriching the pore content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0071] The invention provides a method for preparing a sodium-ion battery negative electrode mesh polymer material, comprising the following steps:

[0072] (1) prepare the dinitrile monomer containing N, O and S;

[0073] (2) the obtained dinitrile monomer is mixed with anhydrous zinc chloride to obtain a mixture;

[0074] (3) Under vacuum conditions, the mixture is subjected to a polymerization reaction to obtain a polymerization product;

[0075] (4) Grinding the polymer product into powder, stirring in an acid solution, and then washing until neutral to obtain the network polymer material.

[0076] The applicant found that if the structure of the dinitrile monomer does not contain N, O and S heteroatoms, the performance of the polymer material prepared is not good, and if the molecular structure is small, such as similar terephthalonitrile structure, its prepared Porous materials have more internal micropores, larger specific surface area, and larger non-effective area. ...

Embodiment 1

[0116] A preparation method for a sodium ion battery negative electrode network polymer material, comprising the following steps:

[0117] (1) Synthesis and purification of the dinitrile monomer containing N, O, S, wherein, the structure of the dinitrile monomer is as shown in the following formula:

[0118]

[0119] In the structure of the above formula, Ar1 is a benzene ring, Ar2 is a thiophene ring, and Ar3 is a benzene ring;

[0120] The synthetic method of described dinitrile monomer is specifically as follows:

[0121] a) Reference K.Y.Yuan, C.Liu, J.H.Han, G.P.Yu, J.Y.Wang, H.M.Duan, Z.G.Wang, X.G.Jian, Phthalazinone structure-based covalent triazine frameworks and their gas adsorption and separation properties, RSC Adv.2016, 6, From 12009 to 12020, the preparation, synthesis and purification of the intermediate product PHPZ-CN were carried out; refer to the literature J.H.Han, K.Y.Yuan, C.Liu, J.Y.Wang, X.G.Jian, Donor–acceptor copolymers containing the phthalazino...

Embodiment 2

[0131] The difference between this embodiment and embodiment 1 is that: in step (3), the temperature is raised to 700° C., and the others remain the same as in embodiment 1.

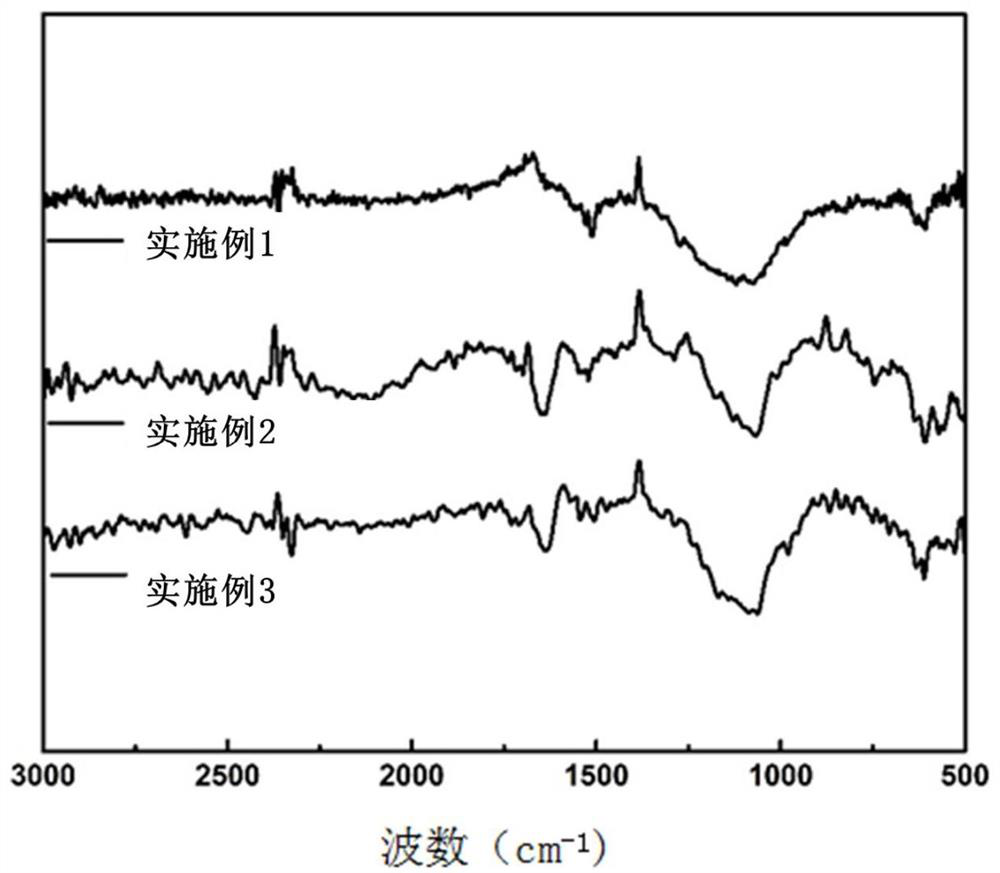

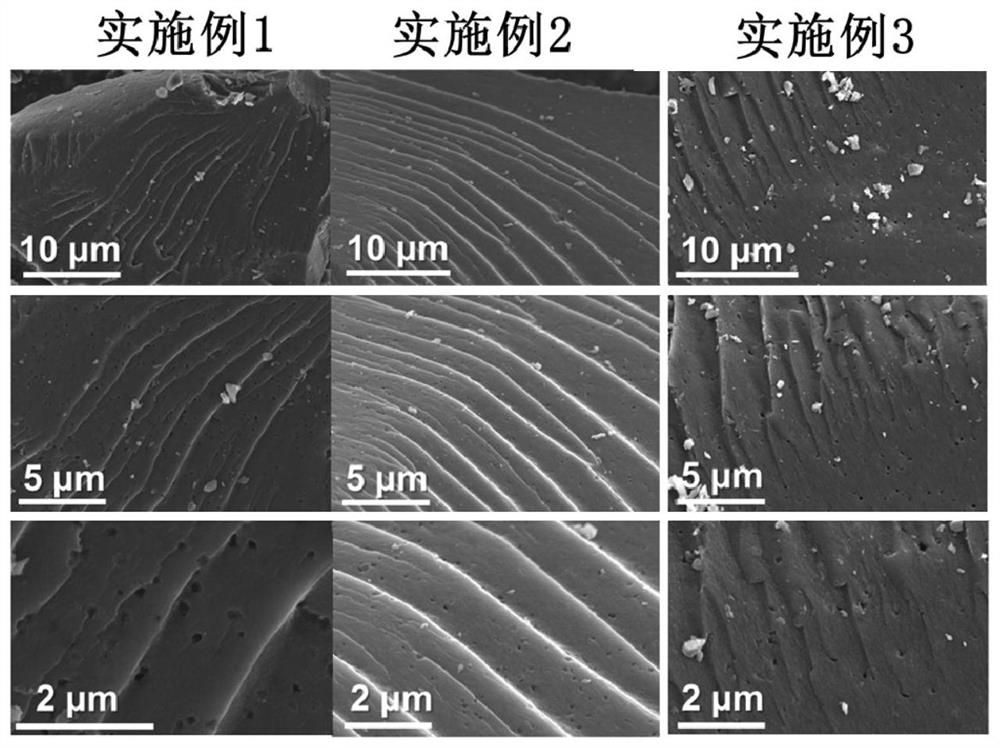

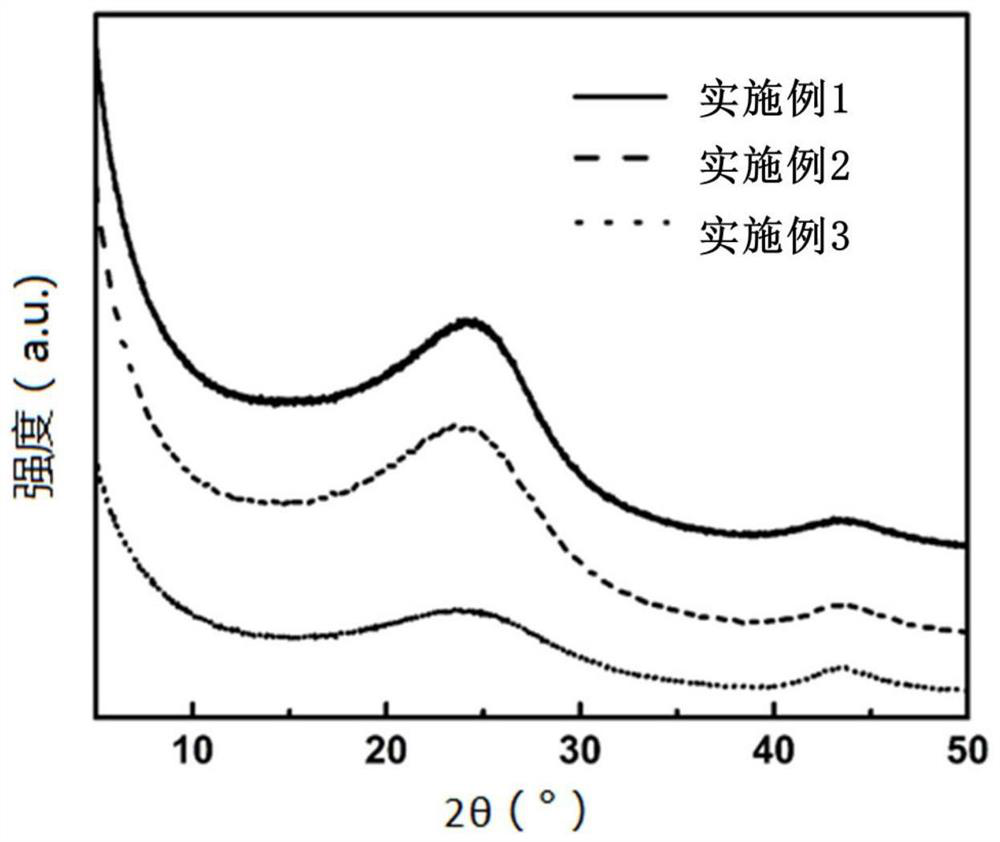

[0132] The specific surface area of the network polymer material of the present embodiment is 1155m 2 / g, the pore volume is 0.71cm 3 / g, the interlayer spacing is 0.374nm, and the contents of N and S are 5.11wt.% and 0.72wt.%, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com