Low-cost porous carbon microsphere and preparation method thereof

A porous carbon, low-cost technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the cost and preparation process hindering the application and promotion, high yield of difficult porous carbon microspheres, uniform particle size and Less impurities, etc., to achieve the effect of regular structure, low price and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

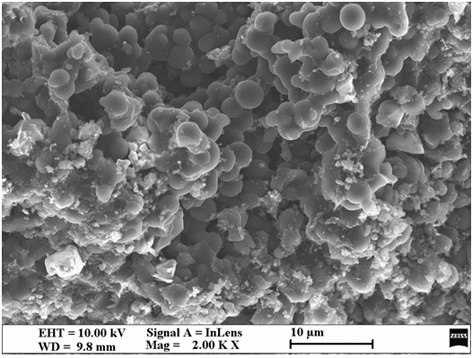

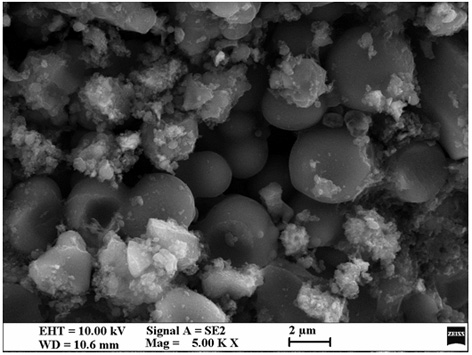

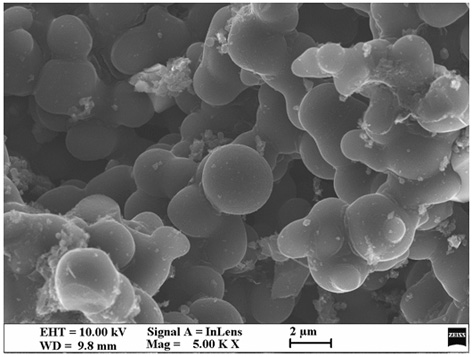

Image

Examples

Embodiment 1

[0038] The sucrose and aluminum sulfate are weighed together as raw materials according to the mass ratio of 1:1, and water is used as the solvent, and the raw material and the solvent are mechanically stirred according to the mass ratio of 1:4.5 (stirring temperature is 50°C, stirring time is 1h, stirring speed 50 r / min) to make it evenly mixed; after stirring, put the sample in a 60°C oven to dry for 30 hours; put the dried sample in a vacuum drying oven (vacuum degree 1.0×10 5 Pa), heat up to 160°C at a rate of 2°C / min, hold for 3 hours, and cool to room temperature; then put the product in a vacuum furnace (vacuum degree 0.1Pa), heat up to 1500°C at a rate of 10°C / min, Insulate and carbonize for 1 hour, cool to room temperature and take it out; put the carbonized product in 2mol / L hydrochloric acid solution and stir for 5 hours (stirring speed is 50 r / min), filter and separate, and wash the filter residue with deionized water until neutral, then put it at 50℃ After drying ...

Embodiment 2

[0041] Glucose and ferrous sulfate are weighed together as raw materials according to the mass ratio of 2.7:1, and ethanol is used as the solvent, and the raw material and the solvent are mechanically stirred according to the mass ratio of 1:5 (stirring temperature is 30°C, stirring time is 1h, stirring The speed is 200 r / min) to make it evenly mixed; after the stirring, put the sample in an oven at 80°C to dry for 16 hours; put the dried sample in a vacuum drying oven (vacuum degree 1.0×10 3 Pa), heat up to 150°C at a rate of 5°C / min, hold for 3.5 hours, and cool to room temperature; then put the product in a vacuum furnace (vacuum degree 100Pa), and heat up to 1000°C at a rate of 2°C / min, Insulate and carbonize for 3 hours, cool to room temperature and take it out; put the carbonized product in 1mol / L nitric acid solution and stir for 10 hours (stirring speed is 200 r / min), filter and separate, and wash the filter residue with deionized water until neutral, then put it at 80°...

Embodiment 3

[0044] Weigh maltose and aluminum chloride together as raw materials according to the mass ratio of 5:1, use water as the solvent, and mechanically stir the raw material and the solvent according to the mass ratio of 1:3 (stirring temperature is 45°C, stirring time is 2h, stirring The speed is 500 r / min) to make it evenly mixed; after the stirring, put the sample in a 95°C oven to dry for 36 hours; put the dried sample in a vacuum drying oven (vacuum degree 1.0×10 3 Pa), heat up to 165°C at a rate of 25°C / min, hold for 4 hours, and cool to room temperature; then put the product in a vacuum furnace (vacuum degree 80Pa), heat up to 700°C at a rate of 1°C / min, and hold Carbonize for 5 hours, cool to room temperature and take it out; put the carbonized product in 6mol / L hydrochloric acid solution and stir for 4.5 hours (stirring speed is 500 r / min), filter and separate, wash the filter residue with deionized water until neutral, and then put it in 140℃ Dry in an oven for 2 hours t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Aperture size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com