Impregnating compound for enhancing quartz fiber tensile strength

A quartz fiber and tensile strength technology, applied in the field of quartz fiber production and manufacturing, can solve the problems of tensile strength attenuation, affecting high temperature performance, etc., to achieve high tensile strength, good production process and performance, and less hairiness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

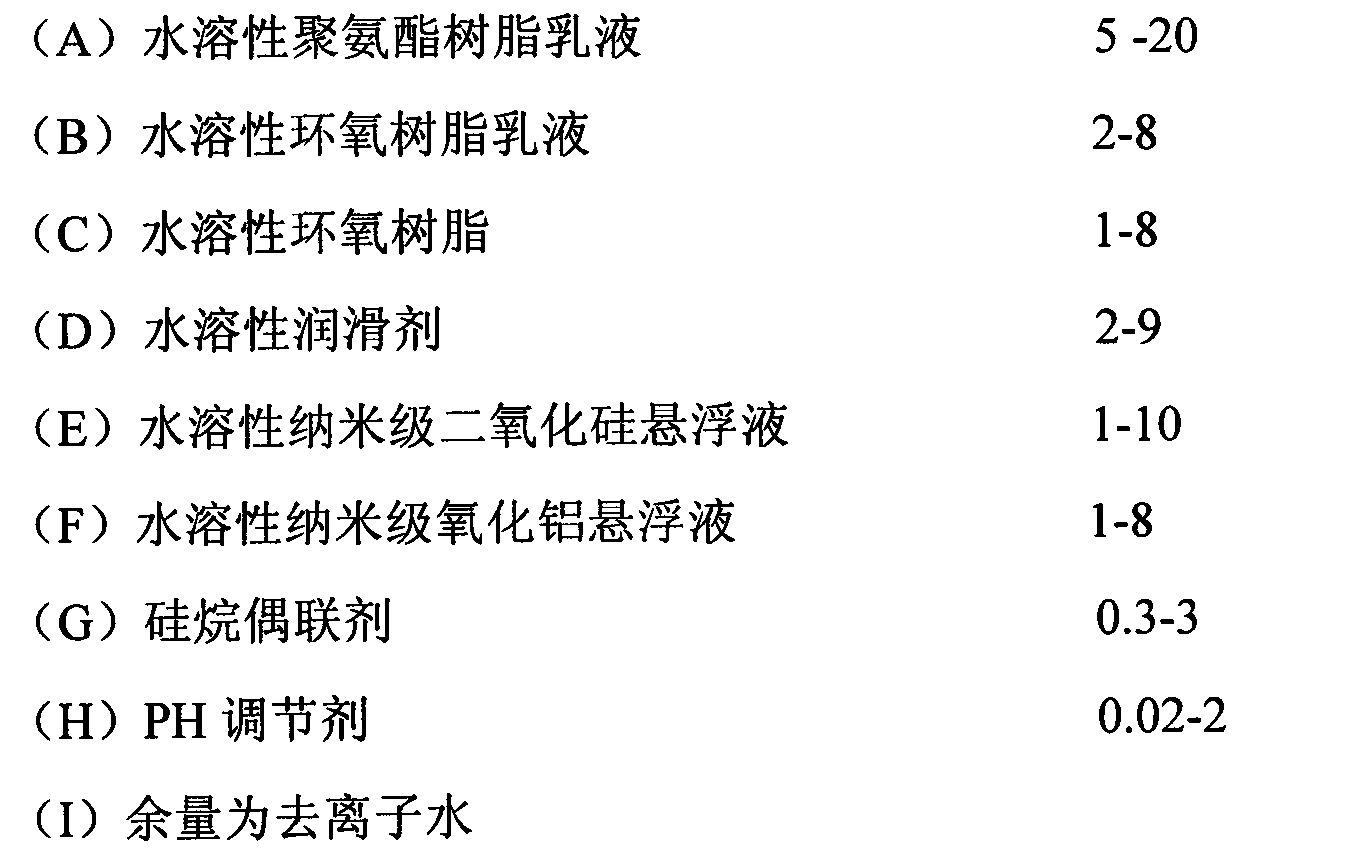

[0019] The present invention is an emulsion composed of the following components: water-soluble polyurethane resin emulsion, water-soluble epoxy resin emulsion, water-soluble epoxy resin, water-soluble lubricant, water-soluble nanoscale silica suspension, water-soluble nanoscale Alumina suspension, silane coupling agent, pH adjuster and deionized water. The polyurethane resin emulsion is made by emulsification of water-soluble polyurethane resin, its molecular weight is in the range of 4000-6000, the average particle diameter of the emulsion is 0.2-2.0 microns, and the water-soluble polyurethane resin emulsion accounts for 5-20% of the total weight of the sizing agent; The epoxy resin emulsion is made of epoxy resin emulsification, its molecular weight is in the range of 300-1000, the average particle diameter of the emulsion is 0.2-2.0 microns, and the water-soluble epoxy resin emulsion accounts for 2-8% of the total weight of the sizing agent; The epoxy resin adopts chemical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com