Patents

Literature

30results about How to "No orange peel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Novel colorizing water-based woodware top coat and preparation method thereof

ActiveCN103232797AImprove permeabilityHigh wetting primer effectPolyurea/polyurethane coatingsPolymer scienceEmulsion

The present invention relates to the fields of water-based wood lacquer colorizing paints and color matching water-based woodware top coats, and particularly relates to a novel colorizing water-based woodware top coat and a preparation method thereof. The novel colorizing water-based woodware top coat comprises the following components, by weight: 30-40% of a polyurethane emulsion, 5-10% of a film-forming agent, 0.1-0.5% of a defoamer, 20-30% of a solvent, 0.1-0. 5% of a pH adjusting agent, 0.1-0.5% of a leveling agent, 0.1-0.5% of a bactericide, 1-3% of a thickener, 1-15% of a water-based color concentrate, and the balance deionized water. The present invention has strong colorizing paint permeability, higher primer wetting effects, no contracted sides, black sides, blurs, pittings, orange peels or color differences, improves the padding formula and process of water-based wood lacquers, and enables uniform coloring of colored woodware varnish surfaces.

Owner:SKSHU PAINT

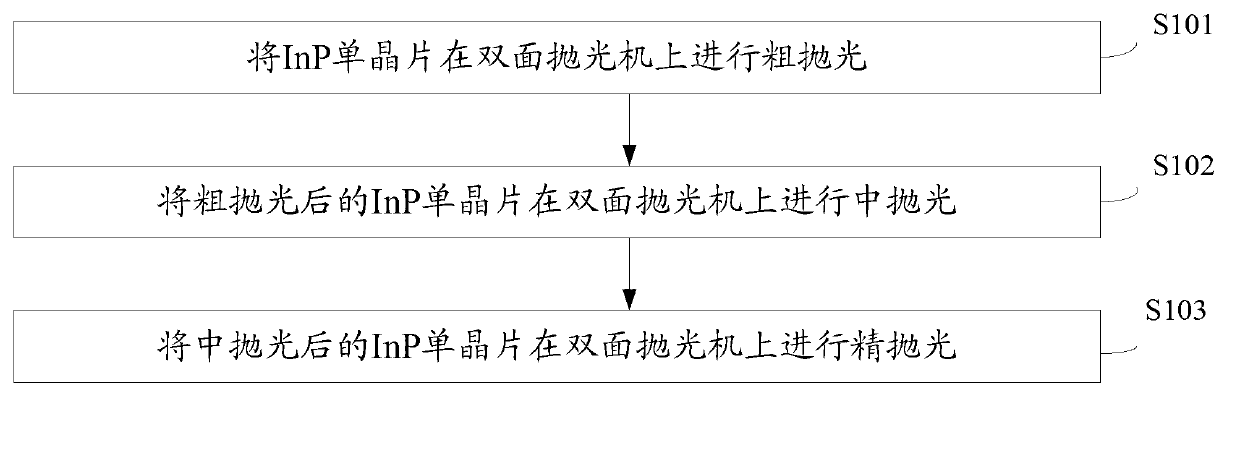

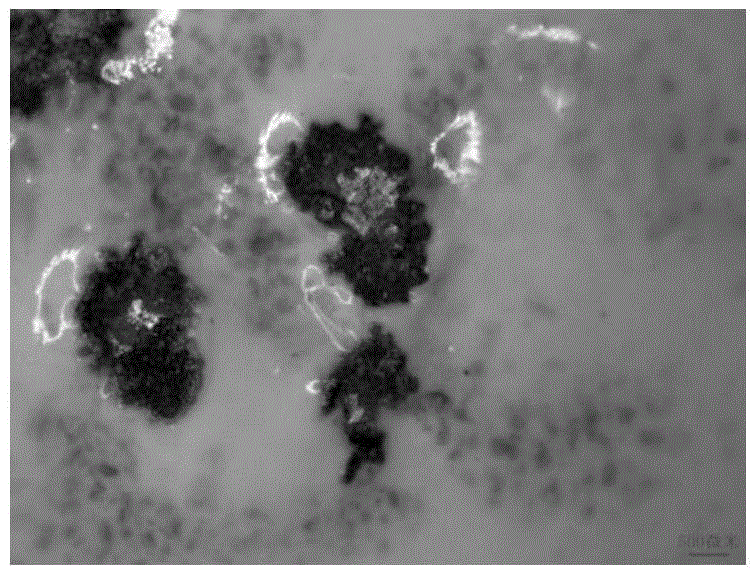

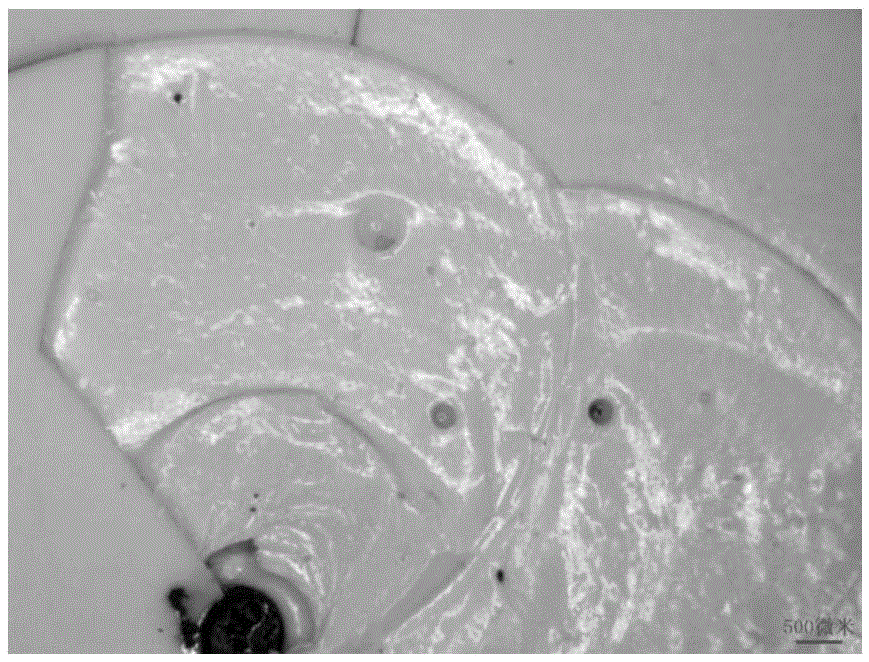

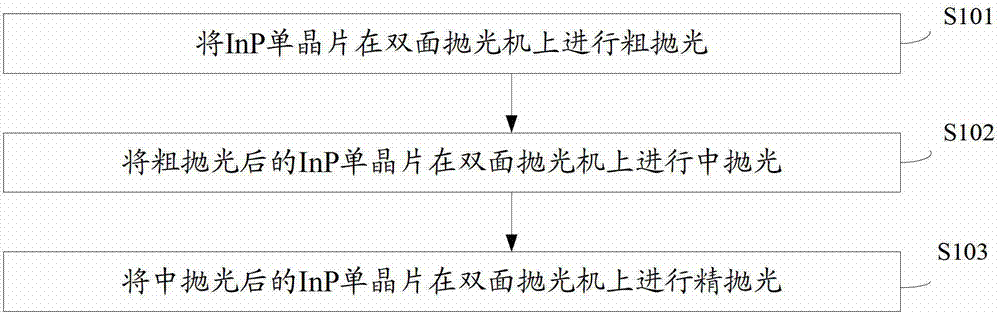

InP single crystal wafer twin polishing method and device

The invention discloses an InP single crystal wafer twin polishing method. The InP single crystal wafer twin polishing method comprises the steps that an InP single crystal wafer sequentially conducts rough polishing, moderate polishing and fine polishing on a twin polishing machine; rough polishing liquid comprises basoid silicon dioxide suspension liquid, deionized water and sodium dichloro cyanurate, volume ratio of the basoid silicon dioxide suspension liquid: the deionized: sodium dichloro cyanurate is 1:10:(1.0-1.8), and pondus hydrogenii (PH) value of the rough polishing liquid is 10-11; moderate polishing liquid comprises basoid silicon dioxide suspension liquid, deionized water and sodium hypochlorite, volume ratio of the basoid silicon dioxide suspension liquid: the deionized: the sodium hypochlorite is 1:15:(0.1-0.5), and PH value of the moderate polishing liquid is 8-9; and fine polishing liquid comprises basoid silicon dioxide suspension liquid and deionized water, volume ratio of the basoid silicon dioxide suspension liquid: the deionized is 1: ( 40-60), and PH value of the fine polishing liquid is 7-8. Surface quality of the InP single crystal wafer which is obtained after polishing by adopting of the method is consistent, and the InP single crystal wafer is crocodile-skin-free, scratching-free and mist-free.

Owner:CHINA ELECTRONICS TECH GRP NO 46 RES INST

Silver alloy for high-temperature enamel inlaid jewelry

ActiveCN105063408AExcellent discoloration resistanceGood high temperature oxidation resistanceIngotCopper

The invention discloses a silver alloy for a high-temperature enamel inlaid jewelry. The silver alloy comprises 93-95 wt% of silver and a trace amount of copper, zinc, palladium, silicone and scandium. A preparation method of the silver alloy comprises the following steps: weighing corresponding amounts of metal raw materials; smelting at 990-1,010 DEG C after mixing; and after smelting, casting into ingots till the temperatures of all the ingredients are equal to obtain the silver alloy. The silver alloy is very suitable for serving as the base of transparent enamel, and excellent in tarnish resistance and high-temperature oxidation resistance, enamel fired by the silver alloy is high in transparency and good in glossiness, can be firmly combined with the base, and the silver alloy is free of surface cracks and wrinkles after being repeatedly fired at high temperature, is relatively high in strength and hardness and can meet the requirement for jewelry setting.

Owner:GUANGZHOU PANYU POLYTECHNIC +1

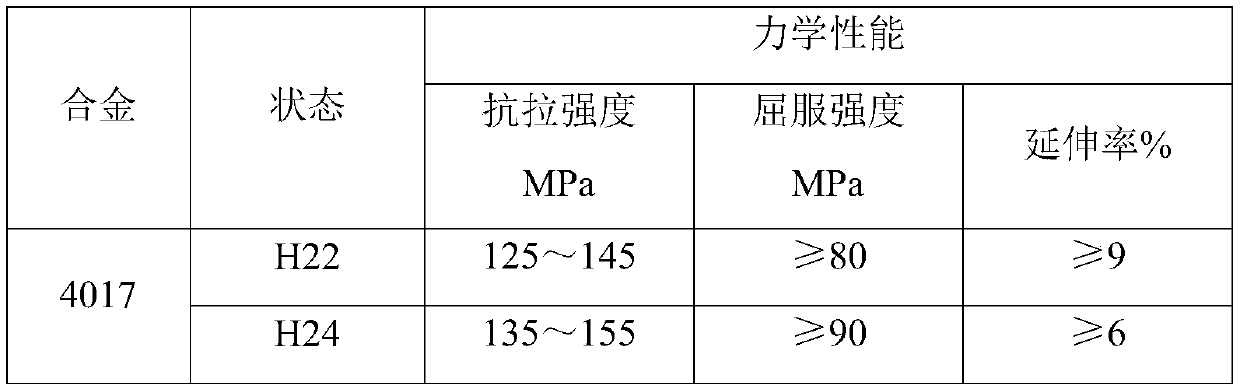

Aluminum alloy checkered plate in state of 4017-H2X and preparation method thereof

The invention relates to an aluminum alloy checkered plate in the state of 4017-H2X and a preparation method thereof. The checkered plate comprises the following raw materials in percentage by weight:0.6-1.6% of Si, less than or equal to 0.7% of Fe, 0.1-0.5% of Cu, 0.6-1.2% of Mn, 0.1-0.5% of Mg, less than or equal to 0.2% of Zn, less than 0.05% of other single impurities, less than 0.15% of total impurities and the balance of Al. The preparation method comprises the following steps of material preparing, smelting and casting; ingot soaking, machining and milling surface; hot rolling; cold rolling and cogging; cold rolling embossing; continuous annealing; and tension correction or crosscutting. The checkered plate in the state of 4017-H22 or 4017-H24 prepared by the preparation method hasno naked eye crack, no orange peel lines and fine surface after being bent at 90 degrees. The checkered plate prepared by the preparation method can be painted and is suitable for being used as building materials and manufacturing decorative parts.

Owner:河南明晟新材料科技有限公司

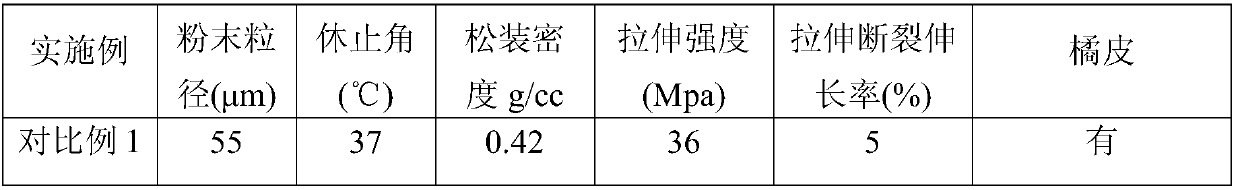

High-molecular powder mixture material and preparation method thereof

The invention provides a preparation method of a high-molecular powder mixture material. The method includes: according to mass percentage ratio of 50-100% to 0-50%, adding fresh powder of a high-molecular powder material and residual powder of a sintered high-molecular powder material into a blending bucket, and performing high-temperature low-speed stirring to eliminate the static electricity between the powders; then performing high-speed stirring and sieving to make the high-molecular powder mixture material. The material has good flowability and is high in apparent density. A sintered product is free of orange peel-like phenomenon and has good surface quality. The residual powder of the high-molecular powder material can be recycled well, so that cost is greatly reduced. The method isenvironment-friendly.

Owner:HUNAN FARSOON HIGH TECH CO LTD

UV surface paint applied to electrostatic coating

ActiveCN101880503AHigh solid contentHigh fullnessPolyurea/polyurethane coatingsEtherElectrostatic coating

The invention discloses UV surface paint applied to electrostatic coating. The UV surface paint contains the following components in part by mass: 24 to 32 parts of aminoacrylic resin, 8 to 12 parts of urethane acrylate, 25 to 31 parts of 1,6-hexanedioldiacrylate, 7 to 11 parts of trimethylolpropane triacrylate, 8 to 11 parts of tripropylene glycol diacrylate, 2.5 to 4 parts of photo-initiator, 0.1 to 0.5 part of flatting agent, 2.5 to 4 parts of butanone and 5.5 to 6.5 parts of acetic ether. The UV surface paint has high solid content and low environmental pollution, is applied to electrostatic coating and has very good atomizing effect; and an obtained workpiece surface film has uniform thickness, is smooth and has no orange peel phenomenon. Meanwhile, a paint film has high fullness, good luster and good hardness. The UV surface paint is particularly suitable for various carpentry workpieces which need multi-face coating such as violins, guitars, seats, photo frames and the like. The painting rate is over 90 percent, the loss is low, the work efficiency is equivalent to that of manual coating with 40 persons, and the UV surface paint can meet the requirement of efficient production.

Owner:佛山市顺德区鸿昌涂料实业有限公司

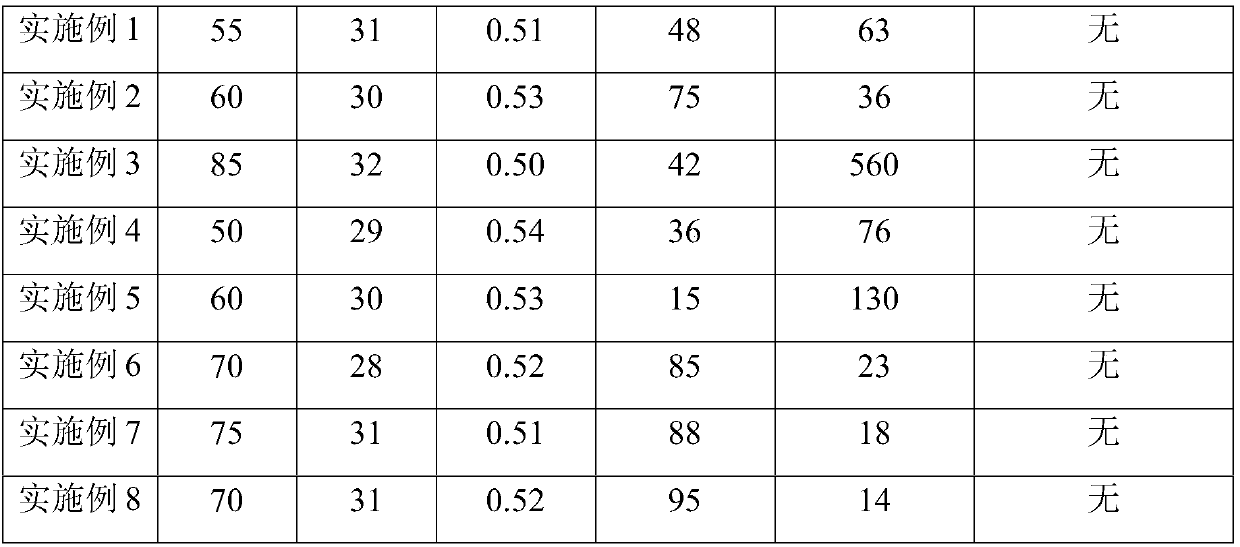

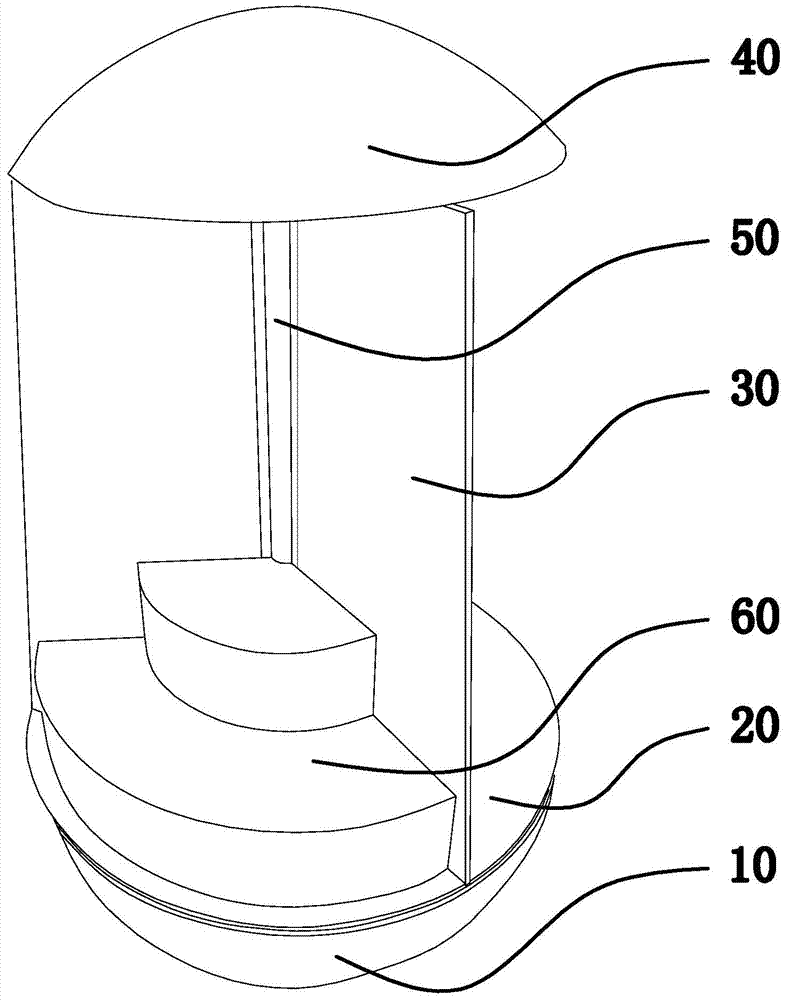

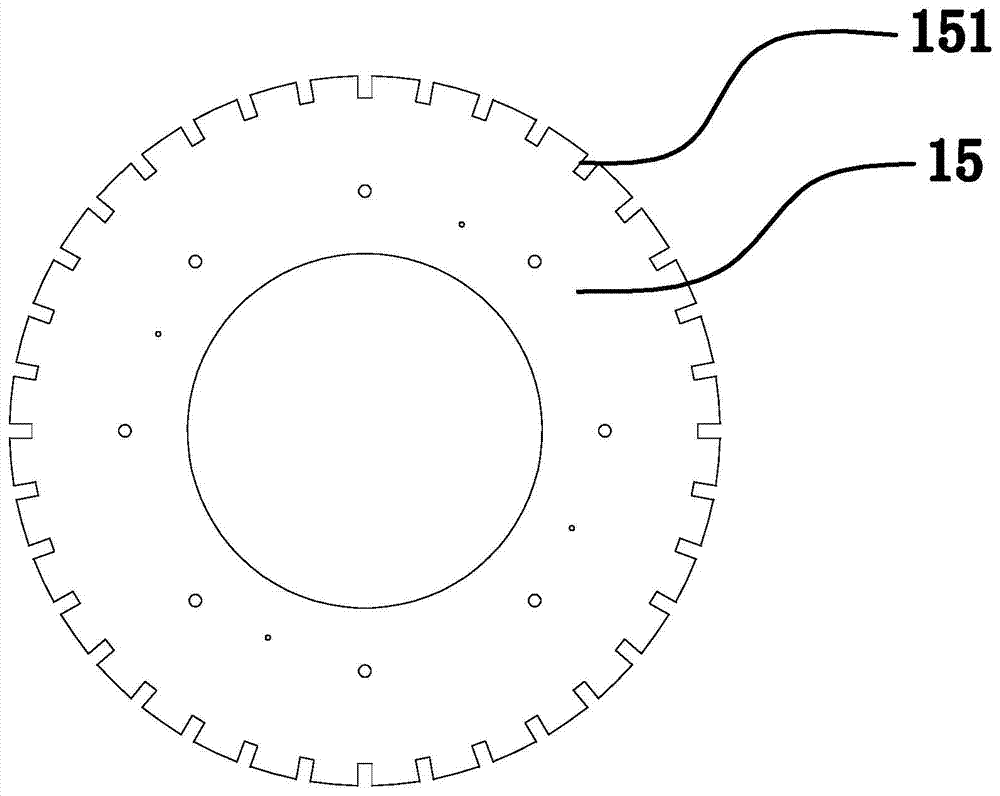

Automatic rotating exhibition stand

InactiveCN103750683AImprove the decorative effectImprove securityShow cabinetsLayered productsEngineeringLayer thickness

The invention provides an automatic rotating exhibition stand which belongs to the technical field of furniture and solves the problems that the existing exhibition stand is difficult to assemble, adjust and transmit. The automatic rotating exhibition stand comprises a base, a motor and a bracket, wherein the base comprises an upper top plate and a lower bottom plate which are respectively provided with a plurality of notched grooves and are connected by a support plate which is provided with clamping parts, and the clamping parts and the notch grooves one-to-one correspond and are tightly clamped to each other; the motor is arranged on the lower bottom plate, and the output end of the motor is connected with a rotating shaft; the extending end of the rotating shaft protrudes from the upper top plate, and the rotating shaft is fixedly connected with an exhibition stand plate and a top support installed at the tail end of the rotating shaft; a separator which is also arranged between the exhibition stand plate and the top support divides the exhibition stand plate into a plurality of storage areas along the axial direction of the rotating shaft; the outer surface of the exhibition stand is sequentially sprayed and / or adhered with a flame retardant fluorescent surface coating with a four-layer structure and the layer thickness is 4 to 16 mm. The automatic rotating exhibition stand has the advantages of simplicity in regulation, convenience in load and unload and novelty in design.

Owner:NINGBO WEIBANG DISPLAY PROPS

Electrophoretic preparation method of RCC (resin coated copper foil)

InactiveCN102071451AFlexible and convenient operationAdapt to the requirements of different product performanceElectrophoretic coatingsEpoxyResin coating

The invention relates to new technology for preparing an RCC (resin coated copper foil), in particular to an electrophoretic preparation method of the RCC. The method provided by the invention comprises the following steps: 1) preparing aqueous solution with solid content of 10-30% from a water borne epoxy resin and a water borne epoxy hardener at a weight ratio of (3-5):1, wherein the aqueous solution is used as cathode electrophoresis liquid for later use; 2) adjusting the pH value of the electrophoresis liquid to be 6.0-7.0 and the temperature to be 18-30 DEG C, taking the copper foil as cathode and the inert metal as anode and performing electrophoresis for 2-12 minutes at a polar distance of 20-45 millimeters and electrophoresis voltage of 4-36V; and 3) washing an electrophoresis film with deionized water and then drying the electrophoresis film for 5-30 minutes at the temperature of 120-160 DEG C to obtain the RCC. The method has the following advantages: VOC (volatile organic compounds) are not released; environmental pollution is avoided; the cost is low; and a resin coating with transfinite thickness (30-150 microns) can be obtained.

Owner:JIANGXI UNIV OF SCI & TECH +1

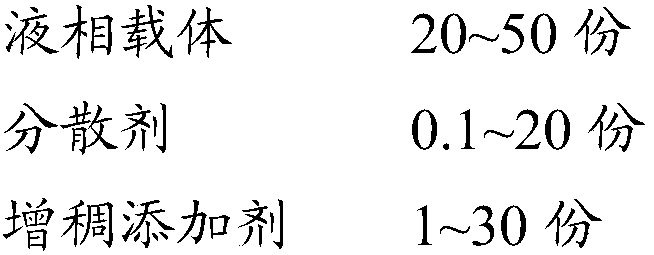

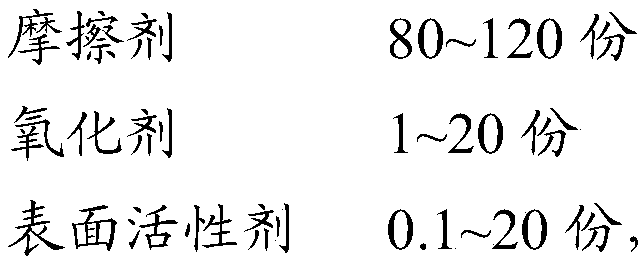

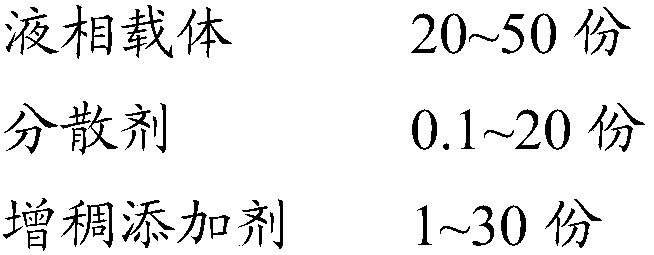

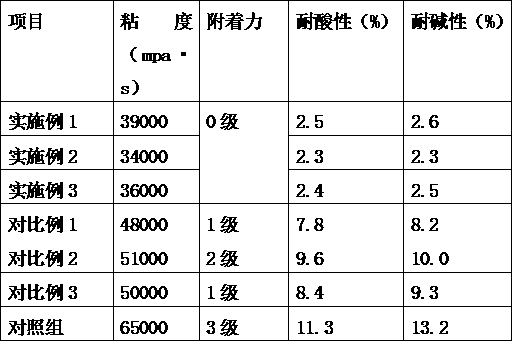

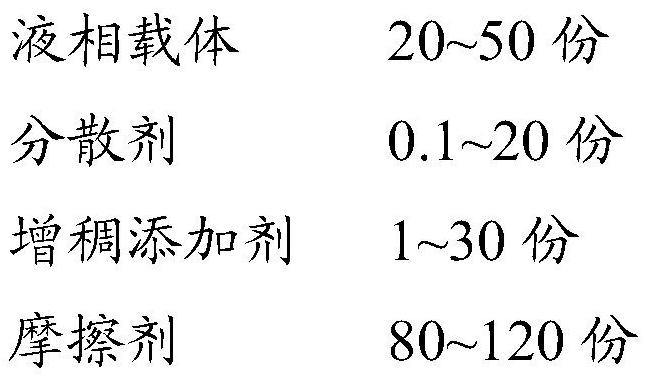

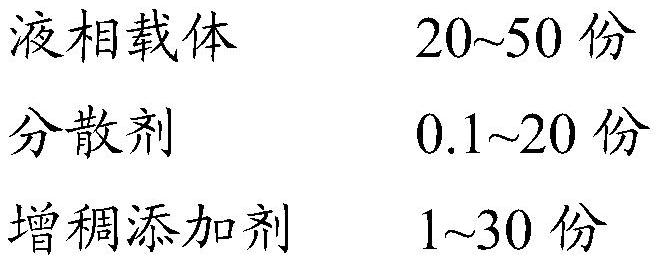

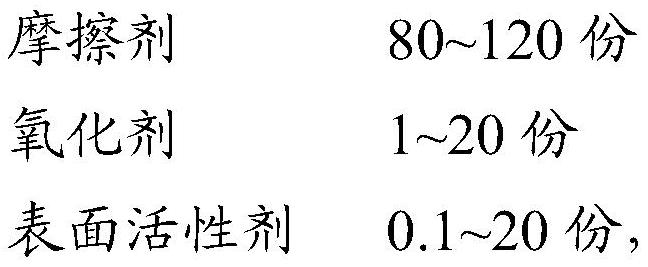

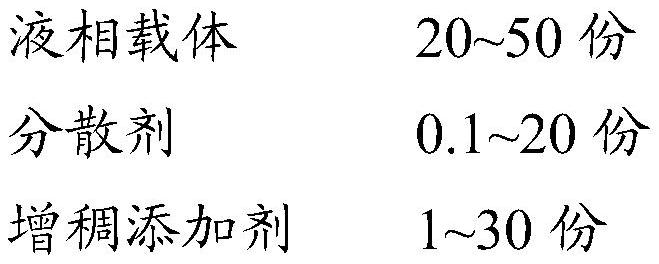

Metal free-form surface polishing liquid and preparation method and application thereof

ActiveCN109054656AImprove continuous polishing efficiencyGuaranteed uniformityPolishing compositions with abrasivesMetal freeViscosity

The invention provides metal free-form surface polishing liquid, and belongs to the field of preparation of polishing liquid. The metal free-form surface polishing liquid provided by the invention isprepared by introducing 20-50 parts of a liquid phase carrier, 0.1-20 parts of a dispersing agent, 1-30 parts of a thickening additive, 80-120 parts of an abrasive, 1-20 parts of an oxidizing agent and 0.1- 20 parts of a surface active material, wherein the components cooperate with one other and work together to ensure a continuous polishing effect of the polishing liquid while solving the technical problems in prior art that viscosity is reduced as the temperature of a polishing system is increased during the polishing, resulting in a decrease in polishing efficiency. At the same time, a preparation method of the metal free-form surface polishing liquid, provided by the invention, is simple and convenient to operate, energy consumption is low, polishing cost is greatly reduced, and metalfree-form surface parts can be polished on a large scale.

Owner:宁波日晟新材料有限公司

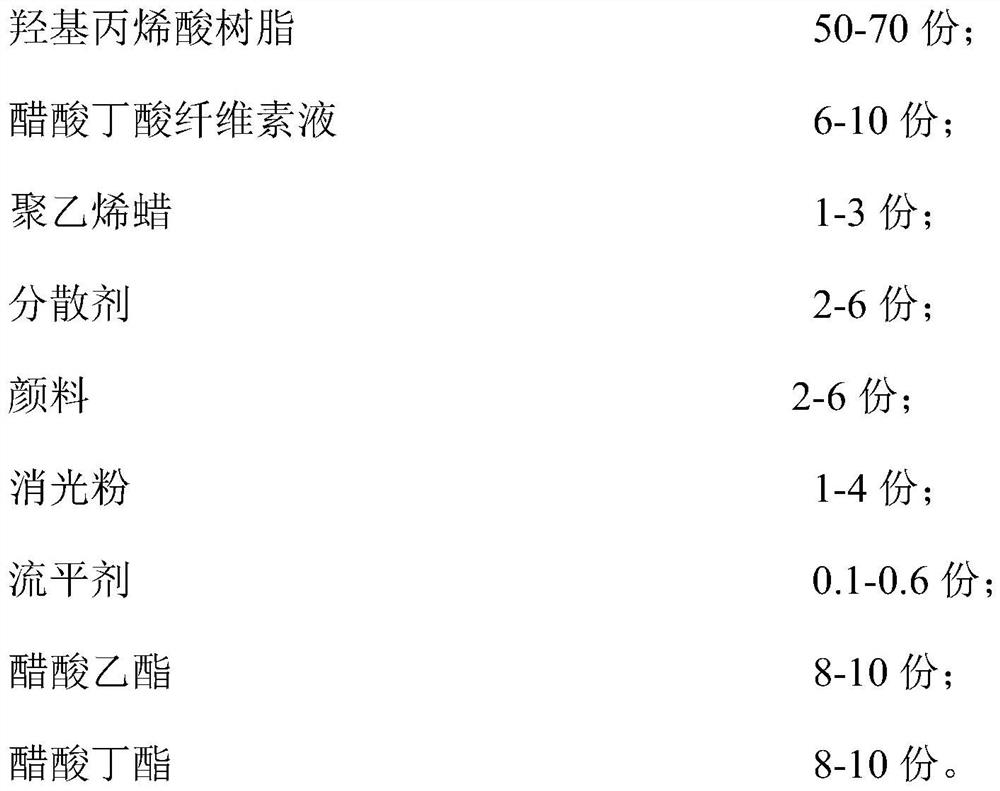

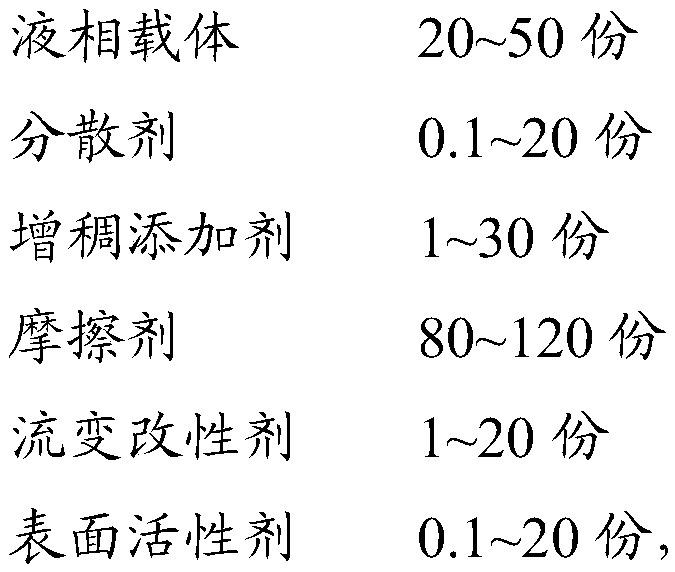

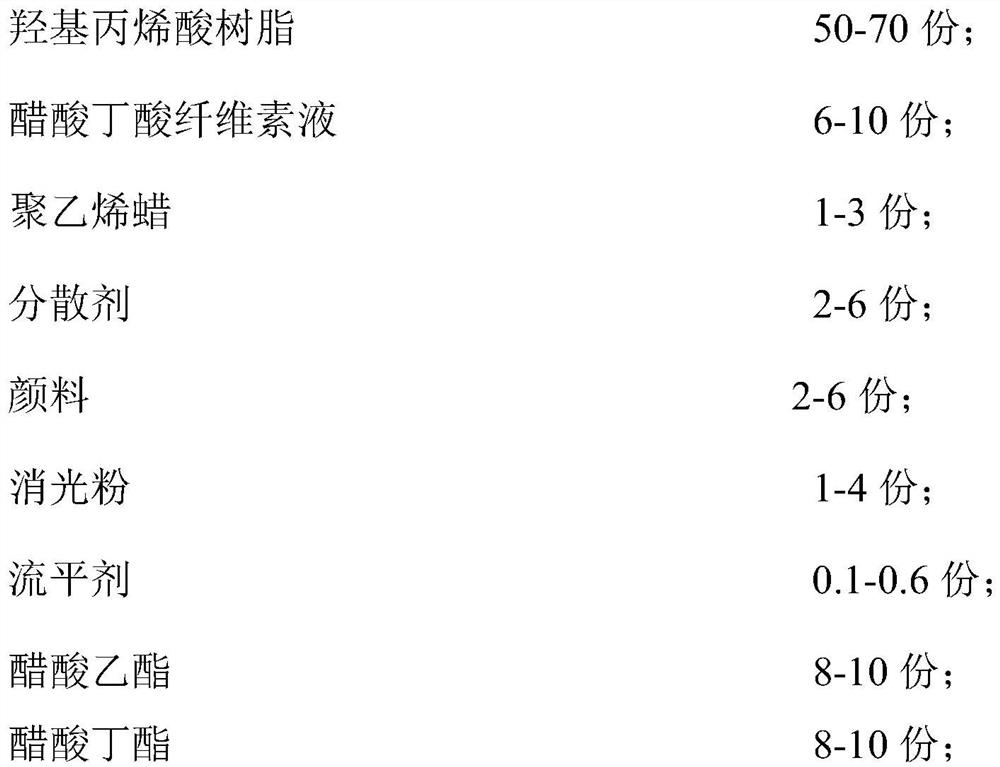

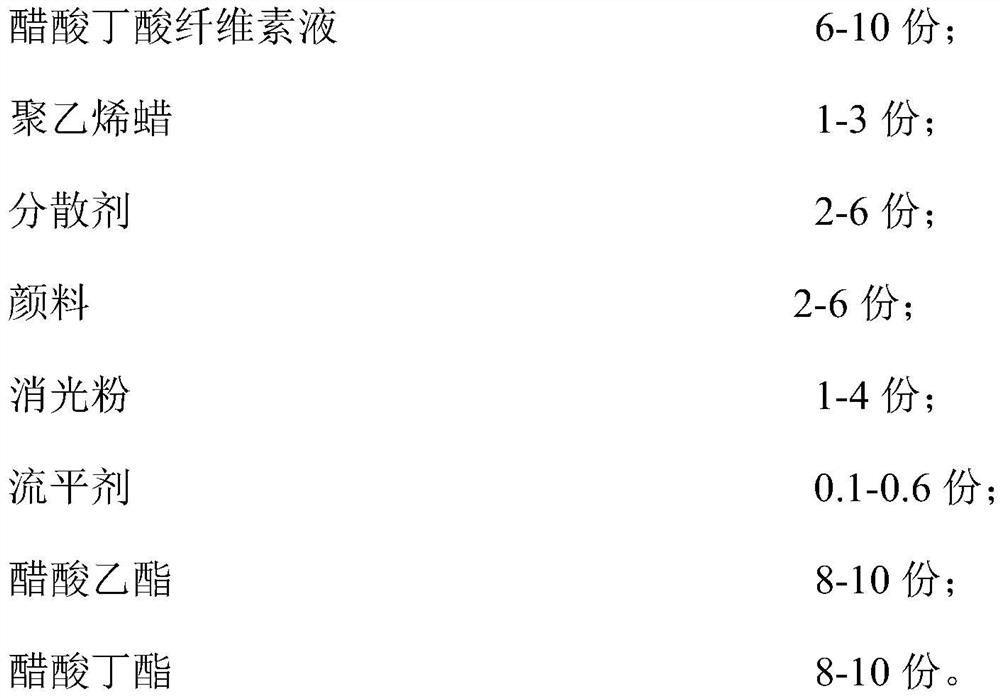

Automotive trim special high-insulation coating and preparation method thereof

ActiveCN112538295AGuaranteed SolubilityImprove the level ofAnti-corrosive paintsAcrylic resinOrganosolv

The invention provides an automotive trim special high-insulation coating and a preparation method thereof. The automotive trim special high-insulation coating is prepared from the following raw materials in parts by weight: 50-70 parts of hydroxy acrylic resin, 6-10 parts of cellulose acetate butyrate liquid, 1-3 parts of polyethylene wax, 2-6 parts of dispersing agent, 2-6 parts of pigment, 1-4parts of extinction powder, 0.1-0.6 part of leveling agent, 8-10 parts of ethyl acetate and 8-10 parts of butyl acetate. Compared with the prior art, the coating provided by the invention does not contain volatile organic compounds, the cross-linking density after curing is large, the performance indexes of a coating in various aspects such as hardness, wear resistance, acid and alkali resistance,salt mist resistance and gasoline resistance are very high, especially the paint film insulativity is very good, and when the voltage of a multimeter is 1000V, the resistance can reach 50G ohm or above. And moreover, during spraying, the coating is good in dispersity, moderate in leveling property, moderate in thixotropy, uniform, free of obvious orange peel, free of needle eye bubbles, free of impurity points and good in smoothness.

Owner:WUHU CHUNFENG NEW MATERIAL

Roller-coating and spray-coating mixed production process for log cabinet body of UV paint furniture

InactiveCN112246582ANo volatile substancesColor stablePretreated surfacesSpecial surfacesNumerical controlJapanning

The invention discloses a roller-coating and spray-coating mixed production process for a log cabinet body of UV paint furniture. The process comprises the following steps of fixed-thickness sanding,UV primer roller-coating for sealing wood pores, paint surface sanding for increasing the UV physical adhesive force in the subsequent procedure, secondary UV primer roller-coating for increasing theplumpness of a paint film, primer sanding, numerical control machining, cut edge physical repairing, UV finish paint spray-coating, paint surface physical repairing treatment, color matching and the like. According to the process, UV paint is applied to a log board, and the thickness of the paint film is greatly related to the wood, texture, hardness, splicing width, moisture, adsorption force anddamp-proof stability of the log board; the problems of miniaturization of production equipment and reduction of production cost are solved; and various adverse effects such as paint surface drawing,napping and granulation cannot be caused during UV paint roller-painting of the log board.

Owner:方庆

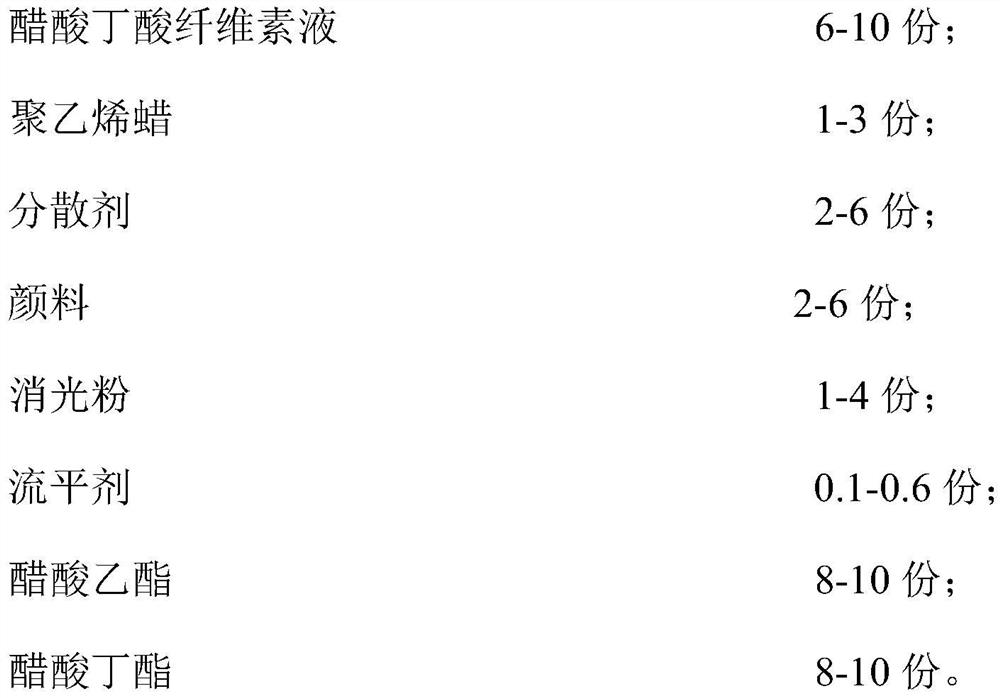

Color printing ink applied to tempered glass

The invention relates to the technical field of color printing ink processing, and discloses color printing ink applied onto tempered glass. The ink is applied to the tempered glass; the viscosity isbetween 30000 and 45000 mpa.s; the production and the use are convenient; the printing effect is good; the dispersity and the compactness of the pigment are determined by the fineness, so that the printing color is uniform and saturated; the used resin has good acid and base resistance and high ultraviolet ray resistance effects; in addition, the viscidity of the pigments can be reduced; the prepared color printing ink has the characteristics of slow volatilization and high drying speed, high attaching degree with tempered glass, and smooth surface. Adverse phenomena of orange peel, edge diffusion and the like cannot occur; the clear and smooth patterns are obtained; meanwhile, adverse problems of white points, pin holes, sagging and the like are solved.

Owner:马鞍山虹润彩印有限责任公司

UV surface paint applied to electrostatic coating

ActiveCN101880503BHigh solid contentHigh fullnessPolyurea/polyurethane coatingsElectrostatic coatingEther

The invention discloses UV surface paint applied to electrostatic coating. The UV surface paint contains the following components in part by mass: 24 to 32 parts of aminoacrylic resin, 8 to 12 parts of urethane acrylate, 25 to 31 parts of 1,6-hexanedioldiacrylate, 7 to 11 parts of trimethylolpropane triacrylate, 8 to 11 parts of tripropylene glycol diacrylate, 2.5 to 4 parts of photo-initiator, 0.1 to 0.5 part of flatting agent, 2.5 to 4 parts of butanone and 5.5 to 6.5 parts of acetic ether. The UV surface paint has high solid content and low environmental pollution, is applied to electrostatic coating and has very good atomizing effect; and an obtained workpiece surface film has uniform thickness, is smooth and has no orange peel phenomenon. Meanwhile, a paint film has high fullness, good luster and good hardness. The UV surface paint is particularly suitable for various carpentry workpieces which need multi-face coating such as violins, guitars, seats, photo frames and the like. The painting rate is over 90 percent, the loss is low, the work efficiency is equivalent to that of manual coating with 40 persons, and the UV surface paint can meet the requirement of efficient production.

Owner:佛山市顺德区鸿昌涂料实业有限公司

Surface polishing solution for free-form surface of glass and preparation method and application thereof

ActiveCN109096924AImprove continuous polishing efficiencyGuaranteed uniformityPolishing compositions with abrasivesFree formViscosity

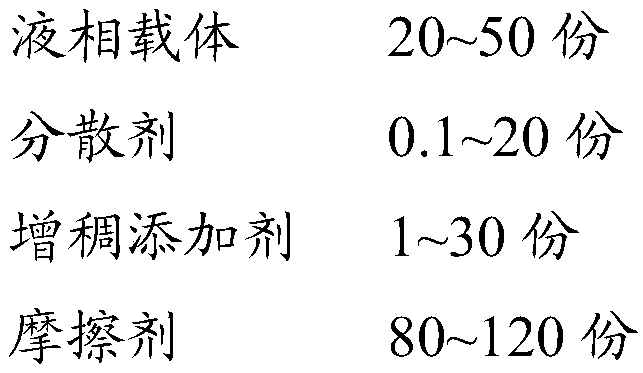

The invention provides a surface polishing solution for a free-form surface of glass and belongs to the preparation field of polishing solutions. The surface polishing solution for the free-form surface of glass is prepared from 20-50 parts of a liquid phase carrier, 0.1-20 pats of a dispersant, 1-30 parts of a thickening additive, 80-120 parts of an abrasive, 1-20 parts of a rheology modifier and0.1-20 parts of a surfactant. The components are intercoordinated and act jointly, so that the technical problem that in the prior art, the reduction in the polishing efficiency is caused by the reduction of the viscosity as along with the temperature raise of a polishing system in a polishing process of the polishing solution is solved while a continuous polishing effect of the polishing solution is guaranteed. Meanwhile, the preparation method of the surface polishing solution for the free-form surface of glass is simple and easy to operate and relatively low in energy consumption, lowers the polishing cost greatly, and a necessary polishing pad in a conventional polishing process is not adopted in the polishing process, and therefore, batches of glass parts can be polished.

Owner:宁波日晟新材料有限公司

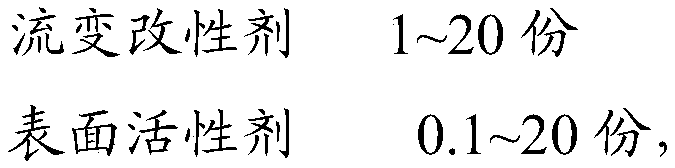

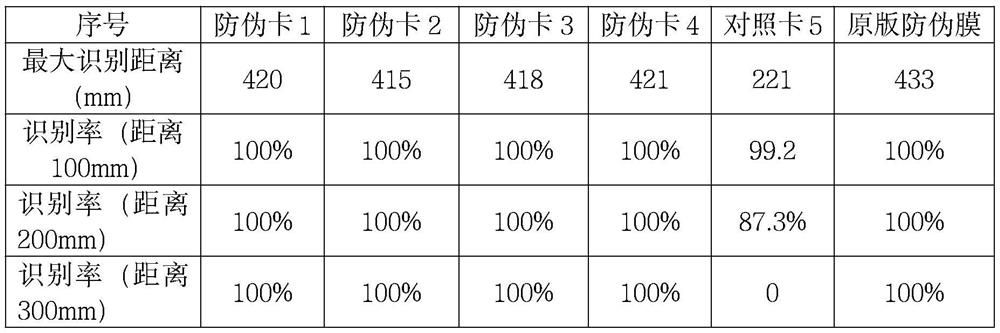

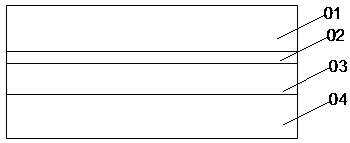

Special orange-resistant belt adhesive film for laser card and preparation method of special orange-resistant belt adhesive film

PendingCN114456735AKeep mirrorNo orange peelFilm/foil adhesive primer layersCoatingsEpoxyPolymer science

The invention relates to an anti-orange belt adhesive film special for a laser identification card and a preparation method and application thereof.The anti-orange belt adhesive film special for the laser identification card comprises a first mirror surface layer, a base material layer, a second mirror surface layer and a bonding layer which are sequentially overlapped, and the first mirror surface layer and the second mirror surface layer are the same in raw material component; the mirror surface layer is prepared from the following raw material components in parts by weight: 30 to 50 parts of epoxy resin, 30 to 50 parts of acrylic ester, 10 to 20 parts of cosolvent, 0.5 to 1.5 parts of catalyst, 5 to 25 parts of diluent, 10 to 20 parts of filler and 1 to 5 parts of initiator. The surface of the base material layer is coated with the mirror surface layer to prepare the orange-resistant belt adhesive film special for the laser card, high-temperature wriggling and deformation of molecules of the base material layer can be resisted in the high-temperature laminating card pressing process, the mirror surface state of the surface of the adhesive film is kept, the surface of the laser card prepared from the adhesive film is free of orange peel phenomenon, the laser effect is fully embodied and is not attenuated, and the service life of the laser card is prolonged. Not only is the attractiveness improved, but also the anti-counterfeiting property is ensured.

Owner:吕拴力

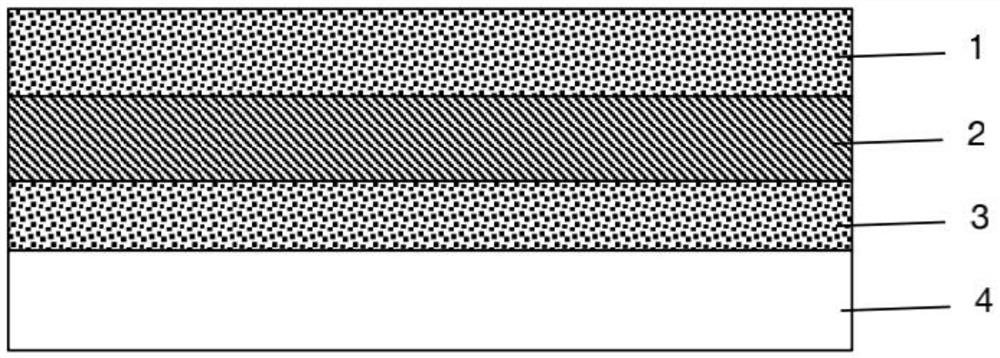

Novel explosion-proof film

PendingCN110698999ASimple structureImprove qualityEster polymer adhesivesMetal working apparatusLaboratory ovenMaterials science

The invention discloses a novel explosion-proof film. The explosion-proof film is composed of a release film, an OCA pressure-sensitive adhesive layer, a PET optical hardening film and a PP protectivefilm in sequence. The film is prepared by the following steps: firstly adding 0.2%-1% of an L-75 curing agent in the OCA pressure-sensitive adhesive, performing uniform stirring, coating the PET optical hardening film with the OCA pressure-sensitive adhesive, performing baking in a baking oven at 100 DEG C for 3-5 min, covering the surface of the OCA pressure-sensitive adhesive layer with the release film, covering the non-corona surface of the PET optical hardening film with the PP protective film, and finally performing cutting according to corresponding parameters by using an explosion-proof film cutting device. The explosion-proof film has a simple structure, high quality, large peeling force and a high-strength explosion-proof function, and is not easy to break; orange peel patternsdo not appear to affect the visual effect after bonding and defoaming; and the explosion-proof film cutting device disclosed by the invention can realize the fast and efficient cutting of the entire-block explosion-proof film, the cut explosion-proof film has no burrs on the edges, and the quality of the final product is high.

Owner:南京五人光学薄膜有限公司

Strength controllable and high tensile aluminium alloy thin plate and its prodn. method

An aluminum alloy thin plate with controllable strength and a manufacturing method thereof relates to an aluminum alloy thin plate and a manufacturing method thereof. Most of the thin plates produced by the existing method are in the annealed state, and the uniformity of the structure is not good, which leads to the problem of premature fracture of the material. The present invention is made of aluminum, copper, magnesium, titanium. The method of the present invention is: in the smelting link, add 100 parts by weight of aluminum, 0.09-0.16 parts of copper, 0.02-0.05 parts of magnesium and 0.018-0.03 parts of titanium, the processing state is H14 and O state, and : Homogenized annealing of the alloy material at 600-620°C; hot rolling when cooled to 500-520°C, the final temperature of hot rolling is not lower than 360°C; cold rolling, processing rate 80-85%; after 430-450°C After the intermediate annealing, the finishing rolling with 25-35% processing rate is carried out. When the product manufactured by this method is formed, the sidewall thinning rate is large, the lug is small, the deep drawing is uniform, the thickness thinning rate can reach 45%, the surface is smooth, and the orange-shaped surface will not be produced.

Owner:NORTHEAST LIGHT ALLOY CO LTD

A kind of glass freeform surface surface polishing liquid and its preparation method and application

ActiveCN109096924BImprove continuous polishing efficiencyGuaranteed uniformityPolishing compositions with abrasivesFluid phaseActive agent

The invention provides a glass free-form surface surface polishing liquid, which belongs to the field of polishing liquid preparation. The glass free-form surface surface polishing liquid provided by the present invention is modified by introducing 20 to 50 parts of liquid carrier, 0.1 to 20 parts of dispersant, 1 to 30 parts of thickening additive, 80 to 120 parts of friction agent, and 1 to 20 parts of rheology. Active agent and 0.1 to 20 parts of surface active substances, the components are coordinated with each other and work together, while ensuring the continuous polishing effect of the polishing liquid, it solves the problem in the prior art that the viscosity of the polishing liquid varies with the polishing system during the polishing process. As the temperature rises, it decreases, resulting in a technical problem that the polishing efficiency decreases. At the same time, the preparation method of the glass free-form surface polishing liquid provided by the present invention is simple, easy to operate, low in energy consumption, greatly reduces the polishing cost, and does not need to use the necessary polishing pad in the traditional polishing process during the polishing process, which can realize High-volume polishing of glass components.

Owner:宁波日晟新材料有限公司

Method for manufacturing metal zinc blank and pipe thereof

The invention relates to a method for manufacturing a metal zinc blank and a pipe thereof. The manufacturing method comprises the following processing steps of: firstly, leading liquid zinc into a cavity of a crystallizer; applying a rotating magnetic field to the liquid zinc in the cavity of the crystallizer in the solidification process of the liquid zinc; and solidifying the liquid zinc into a pipe blank, and directly cold rolling or cold drawing the pipe blank into a required zinc pipe. The method for manufacturing the metal zinc blank and the pipe thereof does not have heating step in the pipe manufacturing process, and the blank has good performance.

Owner:赵宏伟

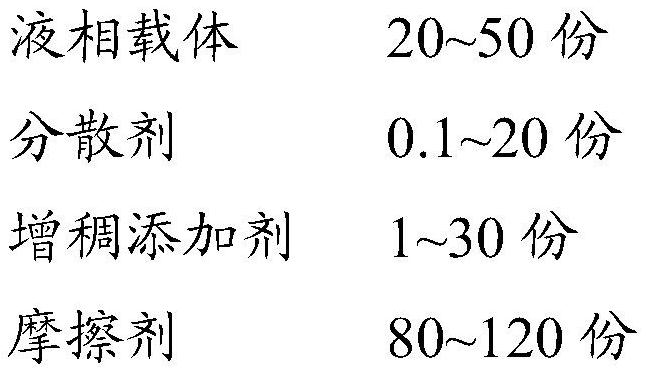

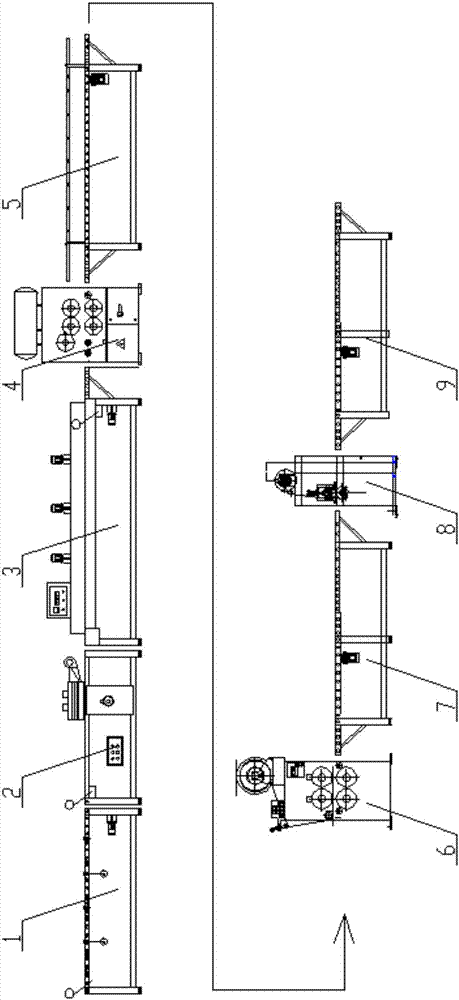

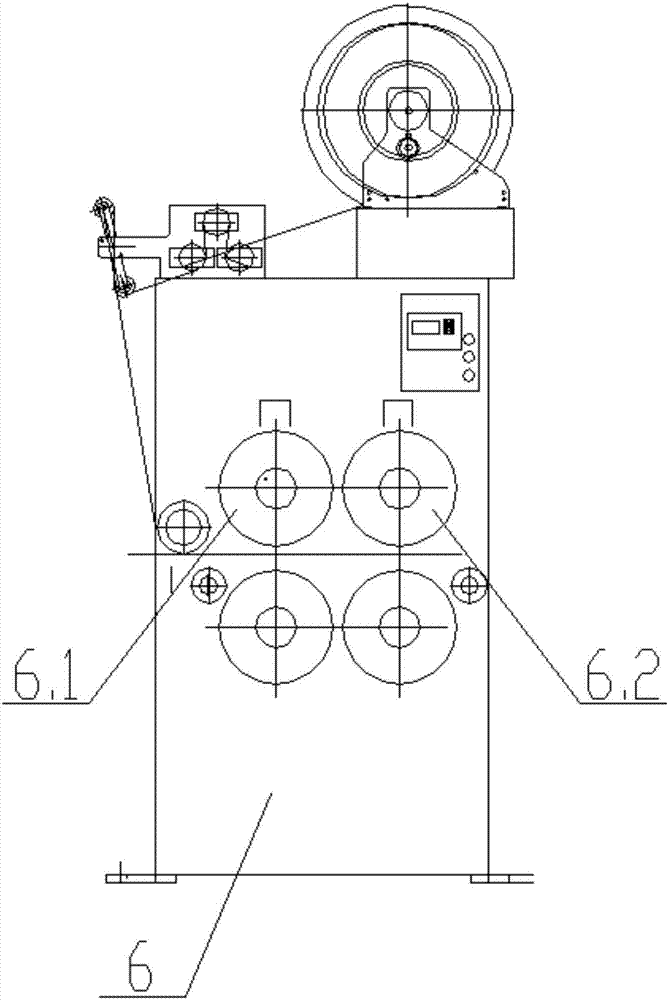

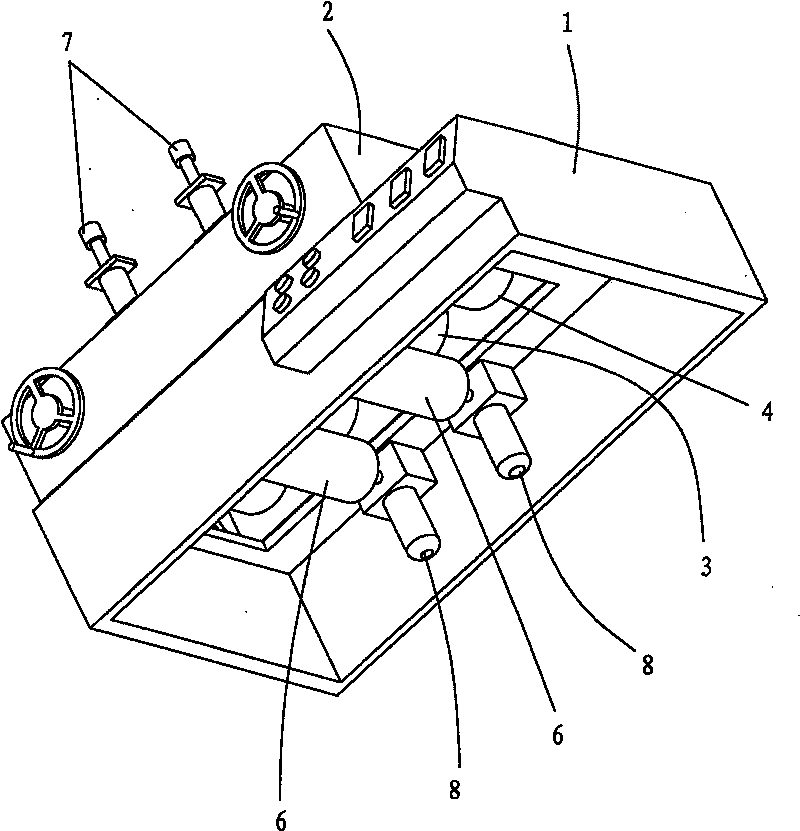

Film-coated decorative plate production line and production process thereof

The invention relates to a film-coated decorative plate production line. The production line is sequentially provided with a roller feeding table, a dust weeper, a plate pre-heater, a glue rolling machine, a combined working table, a rolling film pressing machine, a first roller conveyor, a protective film pressing machine and a second roller conveyor from front to back; the glue rolling machine comprises a metering roller, a gluing roller set and a sweeping leveling roller set are sequentially arranged behind the metering roller, the gluing roller set comprises a gluing roller above and a first supporting roller below, and the sweeping leveling roller set comprises a sweeping leveling roller above and a second supporting roller below; the rolling film pressing machine comprises a front compression roller set and a rear compression roller set which are arranged front and back, the front compression roller set comprises a front steel roller and a front glue roller which are arranged upand down, the rear compression roller set comprises a rear glue roller and a rear steel roller which are arranged up and down. The film-coated decorative plate production line and a production processof the film-coated decorative plate production line have the advantages that the production efficiency is high and the product quality is guaranteed.

Owner:JIANGSU PIVOT NEW DECORATIVE MATERIALS

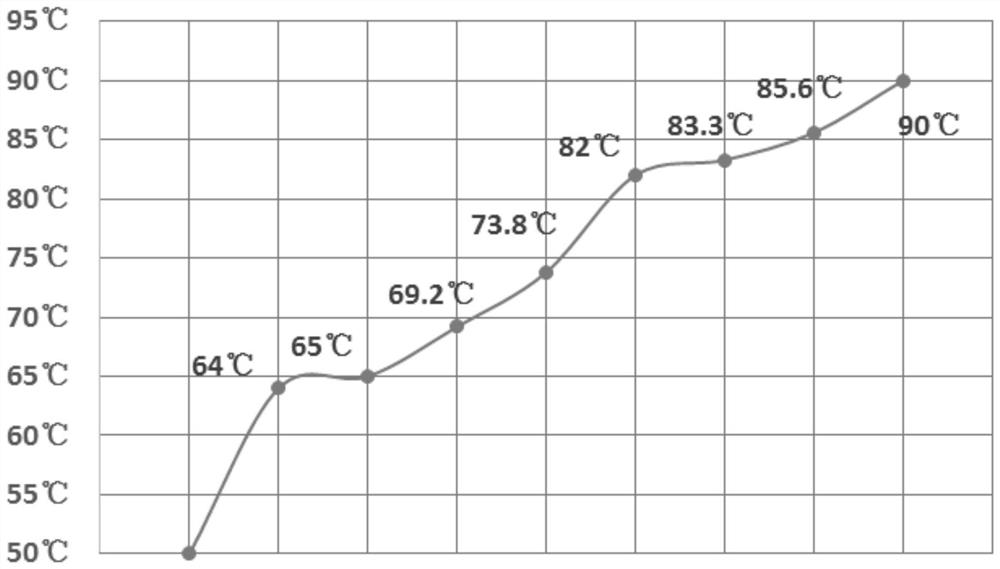

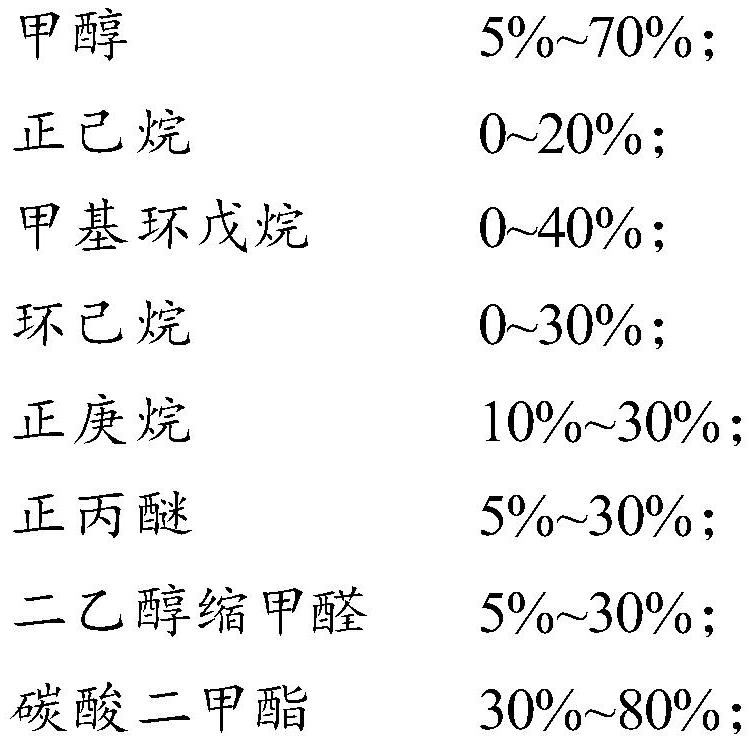

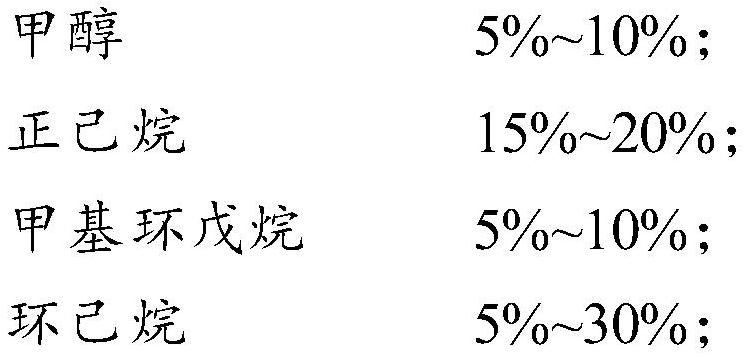

Dimethyl carbonate azeotropic solvent composition, preparation method thereof, automobile low-temperature stoving varnish formula and application

ActiveCN112980234ANo saggingNo orange peelNon-macromolecular adhesive additivesInksDistillationSolvent composition

The invention provides an azeotropic solvent composition. The azeotropic solvent composition comprises dimethyl carbonate and at least two or more compounds capable of respectively forming azeotropic mixtures with the dimethyl carbonate. The dimethyl carbonate azeotropic solvent composition is designed by introducing dimethyl carbonate into an automobile baking varnish solvent, at least two or more compound solvents capable of respectively forming azeotropic mixtures with dimethyl carbonate are adopted, solvent azeotropy is utilized for the first time to form a closely connected distillation range, and therefore, uniform volatilization of the solvent is ensured. The leveling effect of a paint film is greatly improved. The azeotropic solvent composition containing dimethyl carbonate provided by the invention has good leveling property, and can provide glossiness, improve the covering power of pigment, increase the flexibility and adhesive force of a paint film and reduce surface defects such as orange peel, vacuum, fisheye, crater and the like.

Owner:HAIKE GRP RES INST OF INNOVATION & TECH

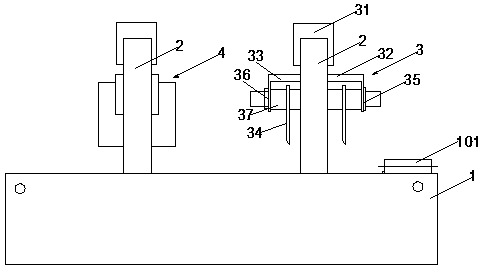

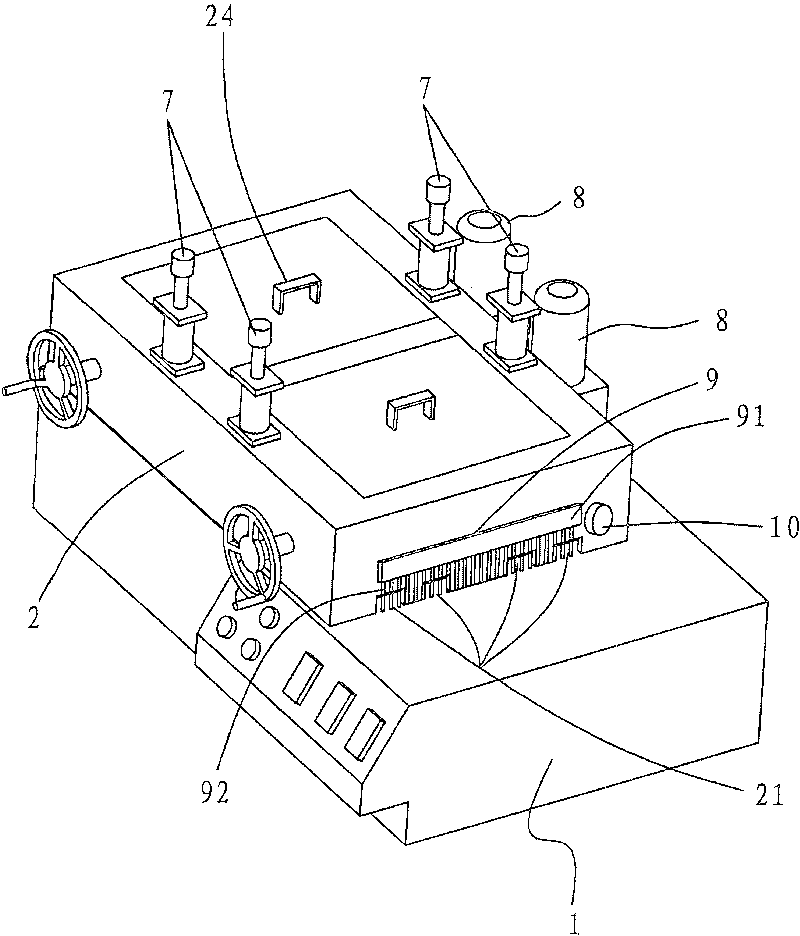

Coating technique of edge sealing strip with high brightness and highly wear resistant and equipment thereof

ActiveCN101279316BIncrease brightnessImprove flatnessPretreated surfacesCoatingsWear resistantBrightness perception

The invention relates to the technical field of a sealing edge sheet coating technique and a coating device thereof, in particular to a high bright and high wearing sealing edge sheet coating technique and device thereof. The technique of the invention is mainly characterized in that a base material is coated with a layer of UV gloss oil by a coating glue roll which rotates along the clockwise direction in vacuum and a coating cavity after being removed static; then the base material is coated with another layer of UV gloss oil by the coating glue roll which rotates along the anticlockwise direction to lead the brightness of the surface of the sealing edge sheet to be higher; the coating cavity of the device adopted is a closed space; the two ends of the coating cavity are respectively provided with at least one inlet and at least one outlet; the two ends of each coating glue roll are respectively provided with a lifting air cylinder; one end of each coating glue roll is connected witha motor respectively; one end of each transmission roll is also connected with the motor; the sealing edge sheet coating technique and the coating device thereof of the invention can coat a thicker glue layer on the base material of the sealing edge sheet by a pair of positive and negative rotating coating glue rolls, thus being not capable of leading on the surface of the sealing edge sheet to appear crocodile skin phenomenon, thus improving flatness and smoothness on the surface of a seal edge.

Owner:东莞市华富立装饰建材有限公司

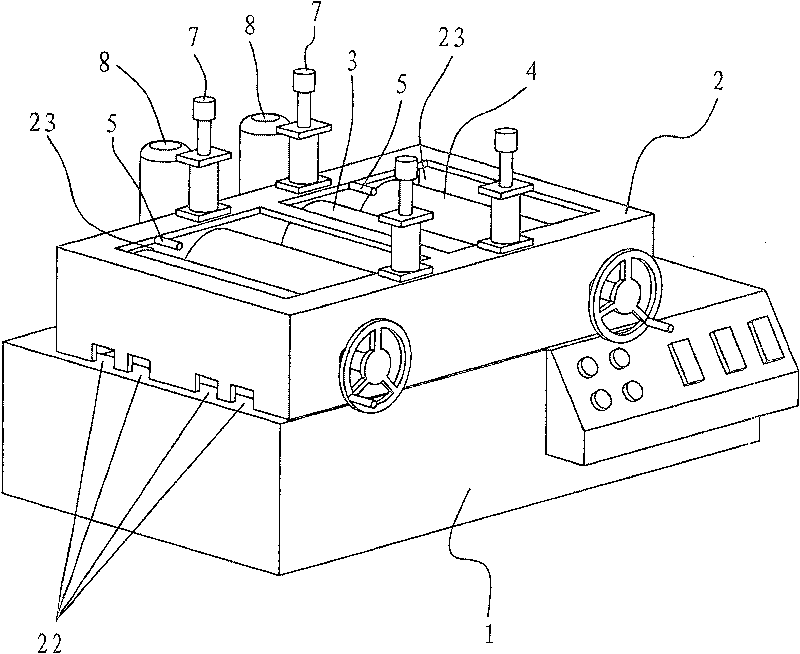

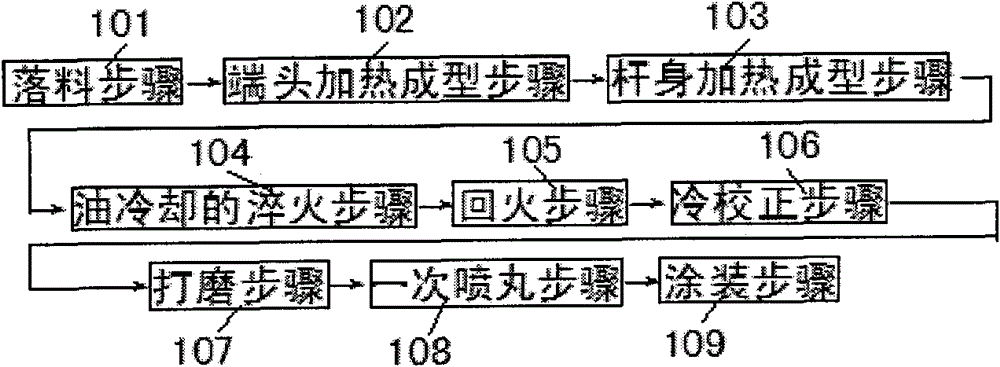

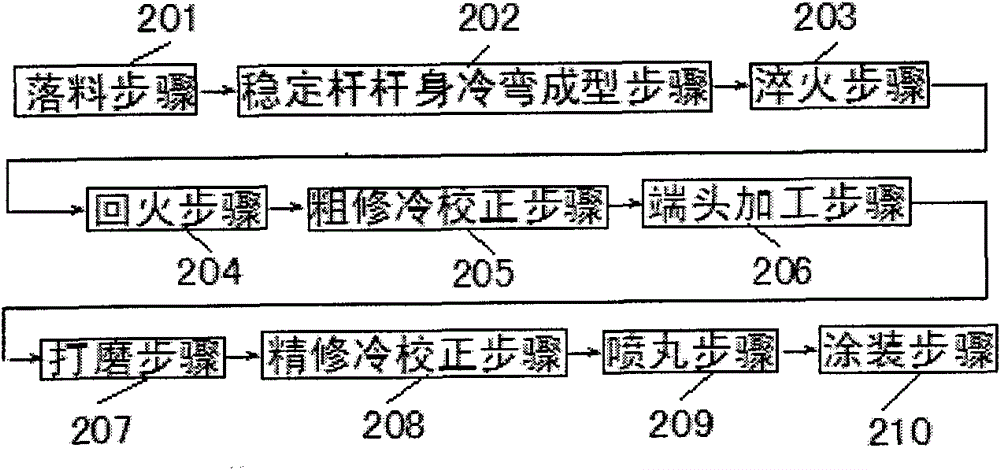

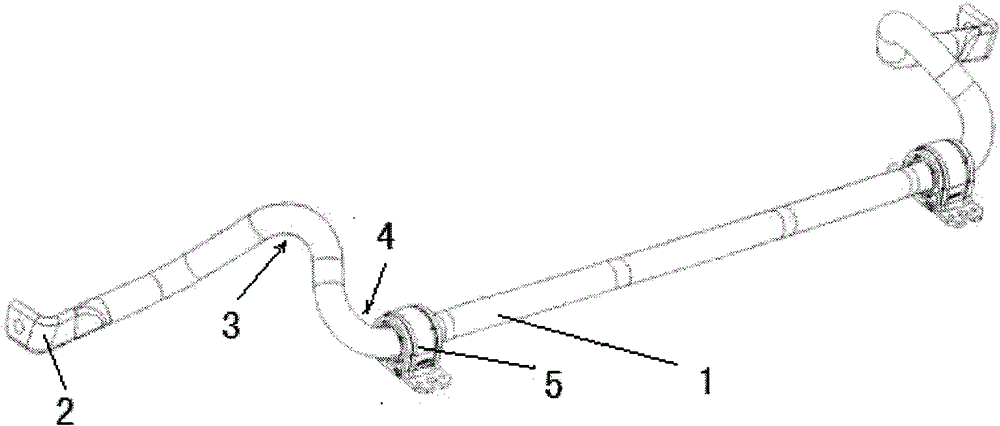

Manufacturing process of hollow stabilizer rod of automobile

The invention relates to a manufacturing process of a hollow stabilizer rod of an automobile, which comprises the blanking step, the step of cold bending and molding of raw materials, the quenching step, the tempering step, the step of rough trimming and cold straightening, the step of end processing, the step of fine trimming and cold straightening, the shot blasting step, and the coating step. By adopting the manufacturing process, the molding speed and the molding quality of the stabilizer rod can be improved. The depth of a decarburization layer on the surface of the stabilizer rod is reduced, and the fatigue life is prolonged. Cracks can be prevented after quenching the stabilizer rod. Compared with a solid stabilizer rod, the hollow stabilizer rod manufactured by adopting the manufacturing process is light in weight, has smooth and clean surface of the stabilizer rod and has no phenomena of orange peels, accumulation and exposure, and technical indexes completely achieve the requirements of automobile parts.

Owner:SHANGHAI SPRING CORP

InP single crystal wafer twin polishing method and device

InactiveCN103100965BConsistent surface qualityFree from scratchesLapping machinesSilica suspensionSingle crystal

The invention discloses an InP single crystal wafer twin polishing method. The InP single crystal wafer twin polishing method comprises the steps that an InP single crystal wafer sequentially conducts rough polishing, moderate polishing and fine polishing on a twin polishing machine; rough polishing liquid comprises basoid silicon dioxide suspension liquid, deionized water and sodium dichloro cyanurate, volume ratio of the basoid silicon dioxide suspension liquid: the deionized: sodium dichloro cyanurate is 1:10:(1.0-1.8), and pondus hydrogenii (PH) value of the rough polishing liquid is 10-11; moderate polishing liquid comprises basoid silicon dioxide suspension liquid, deionized water and sodium hypochlorite, volume ratio of the basoid silicon dioxide suspension liquid: the deionized: the sodium hypochlorite is 1:15:(0.1-0.5), and PH value of the moderate polishing liquid is 8-9; and fine polishing liquid comprises basoid silicon dioxide suspension liquid and deionized water, volume ratio of the basoid silicon dioxide suspension liquid: the deionized is 1: ( 40-60), and PH value of the fine polishing liquid is 7-8. Surface quality of the InP single crystal wafer which is obtained after polishing by adopting of the method is consistent, and the InP single crystal wafer is crocodile-skin-free, scratching-free and mist-free.

Owner:CHINA ELECTRONICS TECH GRP NO 46 RES INST

A kind of automotive interior insulation coating and preparation method thereof

ActiveCN112538295BGuaranteed SolubilityImprove the level ofAnti-corrosive paintsAcrylic resinOrganosolv

The invention provides an automotive interior insulating coating and a preparation method thereof. The raw materials are: 50-70 parts of hydroxyl acrylic resin, 6-10 parts of cellulose acetate butyrate liquid, 1-3 parts of polyethylene wax, and 2-2 parts of dispersant 6 parts, 2-6 parts of pigment, 1-4 parts of matting powder, 0.1-0.6 parts of leveling agent, 8-10 parts of ethyl acetate, 8-10 parts of butyl acetate. Compared with the prior art, the coating provided by the invention does not contain volatile organic compounds, and has a large crosslinking density after curing. The performance indicators in all aspects are very high, especially its paint film insulation is very good. When the voltage of the multimeter is 1000V, the resistance can reach more than 50GΩ. Moreover, it has good dispersion, moderate leveling and thixotropy when spraying, uniform coating, no obvious orange peel, no pinhole bubbles, no impurities, and good smoothness.

Owner:WUHU CHUNFENG NEW MATERIAL

A kind of manufacturing method of antibacterial stainless steel sink

ActiveCN108359914BReduced tendency to crackEasy to processDomestic plumbingSS - Stainless steelAnti bacterial

Owner:JOMOO KITCHEN & BATHROOM

A kind of screen printing ink for in-mold decoration and preparation method thereof

The invention relates to screen printing ink for in-mold decoration. The ink comprises a component A and a component B. The component A is prepared from, by mass, 5-10% of high-boiling-point environment-friendly ester solvent, 15-25% of low-boiling-point environment-friendly ester solvent, 15-20% of tetramethylbenzene, 30-35% of saturated polyester resin, 5-10% of crystalline polyester resin, 6-10% of halogen-free environment-friendly pigment, 5-10% of filler and 1.8-3.5% of assistant. The component B is an isocyanate ester curing agent. An ink layer of the ink is good in flexibility and high in stretch rate, the ink is subjected to high-temperature injection molding and not prone to ink rushing, the adhesive quality of the ink layer and a substrate is good, the ink is small in smell and free of poisons to the human body, a wet film obtained after printing is proper in drying speed and not prone to screen plugging or plate adhering, printability and leveling performance are good, and no orange peel phenomenon is generated.

Owner:一可油墨涂料(深圳)有限公司

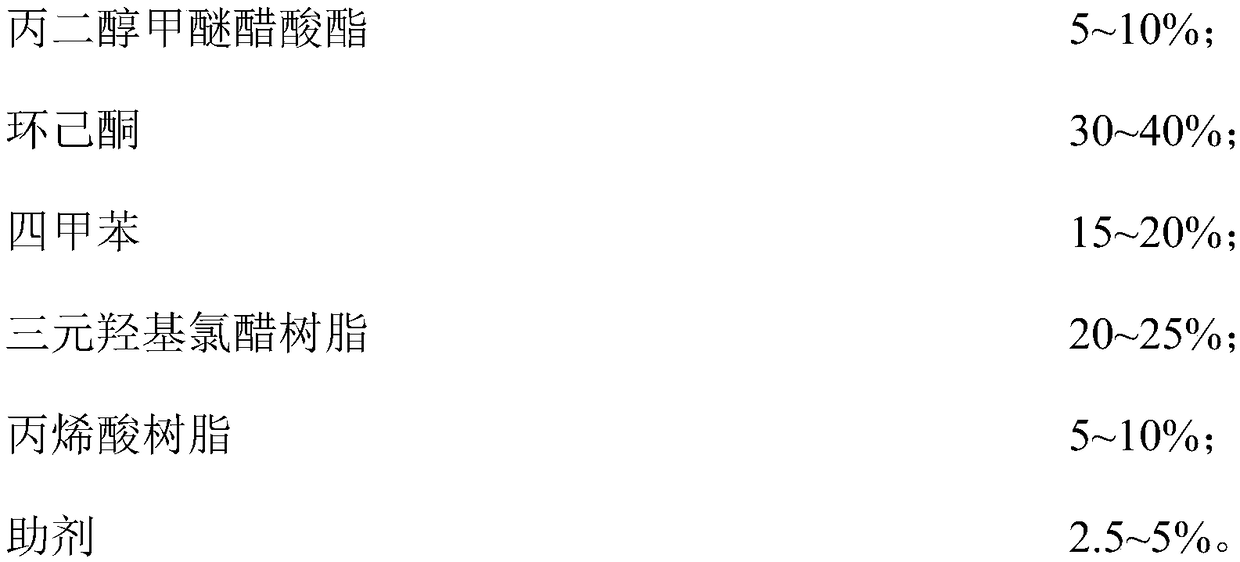

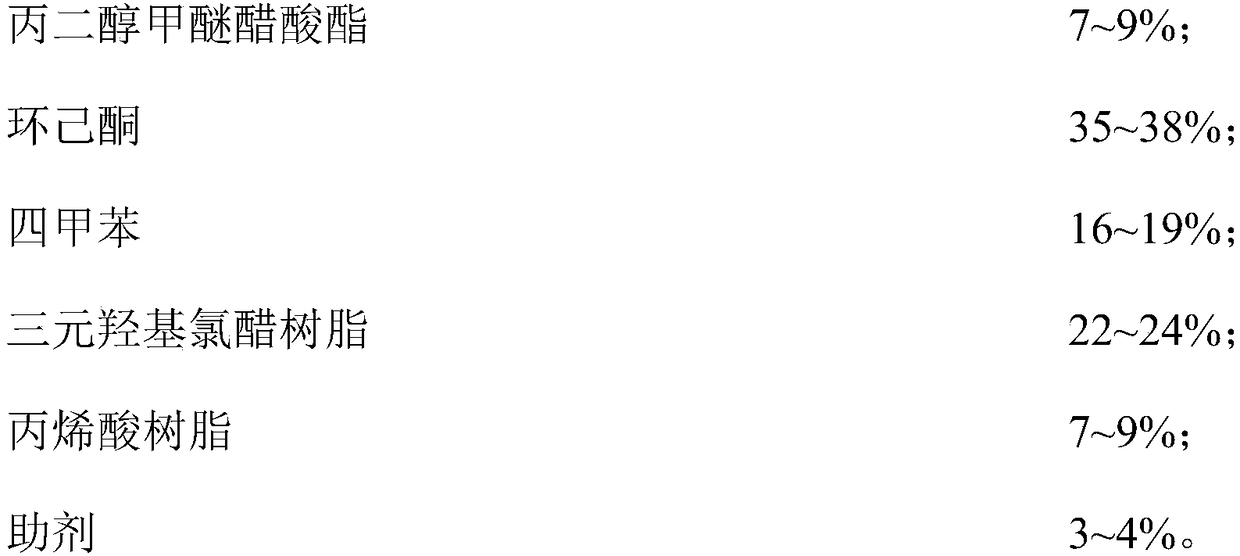

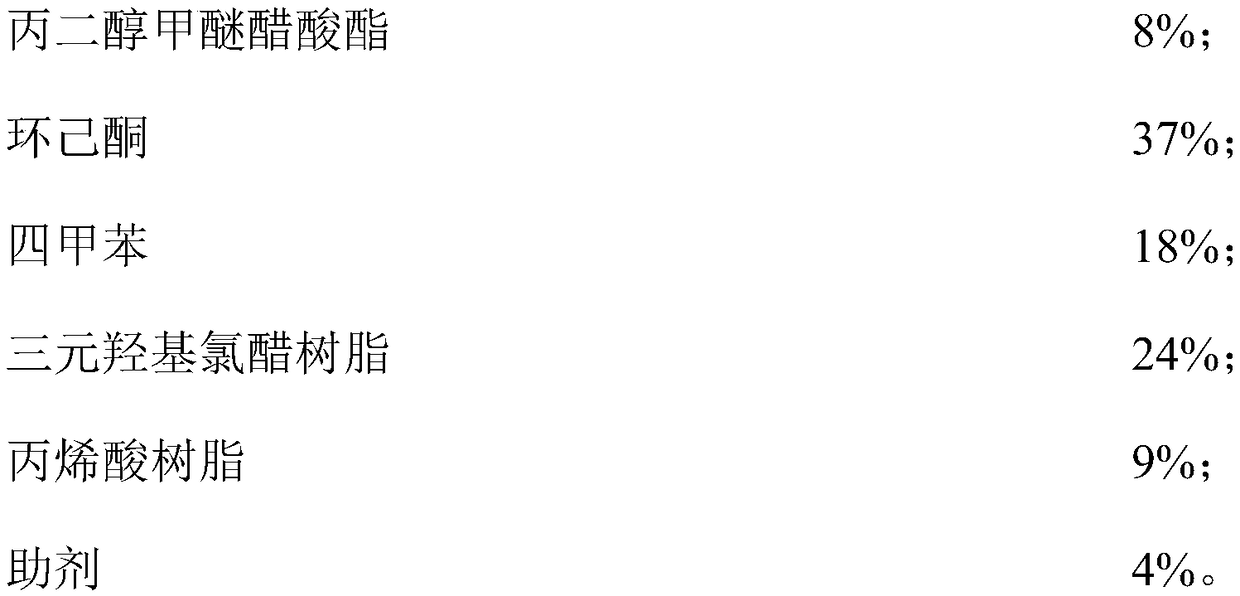

Adhesive glue for in-mold decoration and preparation method thereof

The invention relates to an adhesive for in-mold decoration. The adhesive for in-mold decoration is prepared from, by mass, 5-10% of propylene glycol methyl ether acetate, 30-40% of cyclohexanone, 15-20% of tetramethylbenzene, 20-25% of ternary hydroxyl chloride vinyl acetate resin, 5-10% of acrylic resin and 2.5-5% of assistant. The adhesive has excellent adhesive force, a cross-cut tester test is carried out, the 5B grade is reached, good printability is achieved, no poor printing phenomena such as orange peel and poor defoaming are generated, and good temperature resistance and high temperature and high humidity resistance are also achieved.

Owner:深圳市美丽华科技股份有限公司

A kind of metal free-form surface surface polishing liquid and its preparation method and application

ActiveCN109054656BImprove continuous polishing efficiencyGuaranteed uniformityPolishing compositions with abrasivesFluid phaseMetal free

The invention provides a metal free-form surface surface polishing liquid, which belongs to the field of polishing liquid preparation. The metal free-form surface surface polishing liquid provided by the present invention is introduced by introducing 20-50 parts of liquid phase carrier, 0.1-20 parts of dispersant, 1-30 parts of thickening additive, 80-120 parts of friction agent, 1-20 parts of oxidizing agent and 0.1 ~20 parts of surface active substances, each component coordinates with each other and works together, while ensuring the continuous polishing effect of the polishing liquid, it solves the problem in the prior art that the viscosity of the polishing liquid increases with the temperature of the polishing system during the polishing process. High and low, resulting in a technical problem of reduced polishing efficiency. At the same time, the preparation method of the metal free-form surface polishing liquid provided by the invention is simple and easy to operate, has low energy consumption, greatly reduces the polishing cost, and can realize mass polishing of metal free-form surface parts.

Owner:宁波日晟新材料有限公司

A kind of polymer powder mixed material and preparation method thereof

The invention provides a method for preparing a polymer powder mixed material, which comprises the following steps: the new powder of the polymer powder material and the remaining powder of the polymer powder material after sintering are mixed according to the ratio of 0-50%: 50-100%. The mass percentage is added to the powder mixing barrel, and the high-temperature and slow-speed stirring process is adopted to eliminate the static electricity between the polymer powders, and then the high-speed stirring process is used to sieve to obtain a polymer powder mixed material. The polymer powder mixed material of the present invention has good fluidity, high loose packing density of the powder, no orange peel in the sintered part, good surface quality, and high recyclability of the residual powder of the polymer powder material, which greatly reduces the cost and greatly reduces the cost. The environment is friendly.

Owner:HUNAN FARSOON HIGH TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com