Silver alloy for high-temperature enamel inlaid jewelry

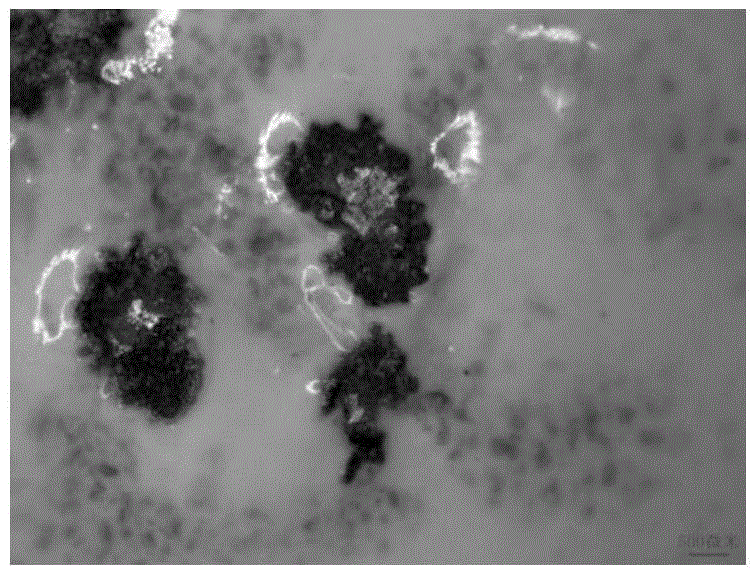

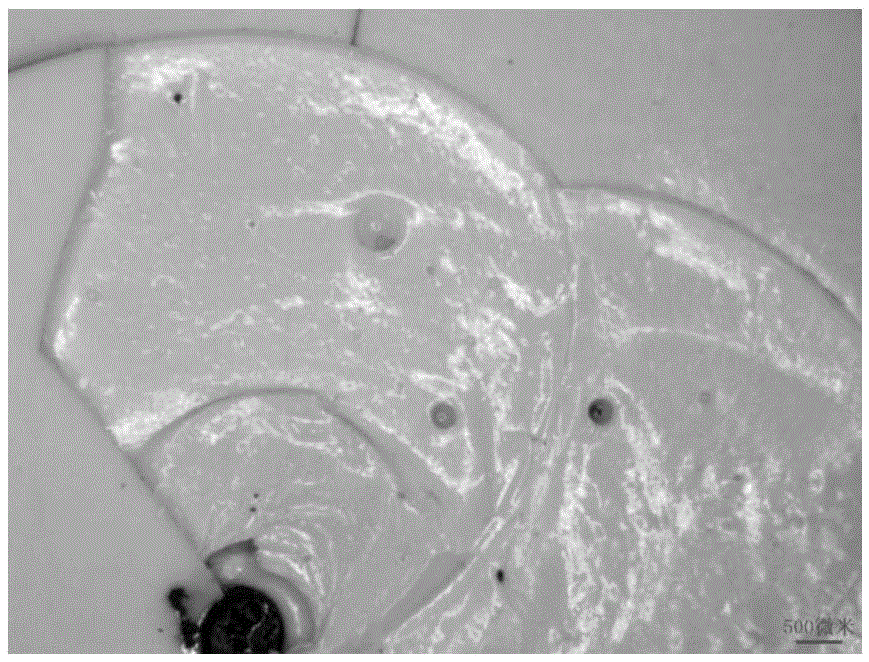

A technology of silver alloy and silver-copper alloy is applied in the field of silver alloy base material for preparing high-temperature enamel, which can solve the problems of orange peel on the surface, air bubbles on the enamel surface, oxidized slag, etc., and achieves good gloss, good high-temperature firing and transparency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] A method for preparing a silver alloy, the method comprising the following steps:

[0036] 1) Weigh the corresponding amount of metal raw materials, the amount of each metal raw material so that the composition of the prepared silver alloy is as the criterion as mentioned above;

[0037] 2) Mix the raw materials weighed above and then smelt them. After the melting is completed, wait for the temperature of each component to be uniform and cast them into ingots.

[0038] Preferably, before the smelting described in step 2), vacuumize to 4.5-5.5 Pa, and then fill in inert gas to a pressure of 0.97-1.03 atm.

[0039] Preferably, the above-mentioned inert gas is argon.

[0040] Preferably, the temperature during smelting in step 2) is 990-1010°C.

[0041] Preferably, in step 2), the temperature of each component to be uniform in temperature is 980-1000°C.

[0042] Preferably, the metal raw material in step 1) is silver-scandium alloy, silver-palladium alloy, silver-copper...

Embodiment 1

[0048] The present embodiment is used for the silver alloy of enamel inlaid jewelry, and its composition comprises the following components by mass percentage: 94.39wt% silver, 2.43wt% copper, 2.35wt% zinc, 0.70wt% palladium, 0.074wt% silicon, 0.008wt% scandium, and the balance is unavoidable impurities.

[0049] The preparation method of silver alloy described in the present embodiment comprises the following steps:

[0050] 1) Weigh the following raw materials in mass percentage: 1.6wt% silver-scandium alloy (containing 0.5wt% scandium), 7wt% silver-palladium alloy (containing 10wt% palladium), 5wt% silver-copper alloy (containing 20wt% copper), 12wt% Silver-zinc alloy (20wt% zinc), 1.5wt% copper-silicon alloy (5wt% silicon), 72.9wt% pure silver;

[0051] 2) Melting in a vacuum induction furnace: Put the above-mentioned weighed raw materials into a graphite crucible, mix well, fill it tightly and close the furnace cover, evacuate to 5.2Pa, then fill with industrial pure arg...

Embodiment 2

[0069] This embodiment is used for the silver alloy of enamel inlaid jewelry, and its composition comprises the following components by mass percentage: 94.20wt% silver, 2.40wt% copper, 2.98wt% zinc, 0.30wt% palladium, 0.053wt% silicon, 0.007wt% scandium, and the balance is unavoidable impurities.

[0070] The preparation method of silver alloy described in the present embodiment comprises the following steps:

[0071] 1) Weigh the following raw materials in mass percentage: 1.5wt% silver-scandium alloy (containing 0.5wt% scandium), 3.1wt% silver-palladium alloy (containing 10wt% palladium), 12.5wt% silver-zinc alloy (containing 20wt% zinc), 1.1wt% copper-silicon alloy (containing 5wt% silicon), 2wt% copper-zinc alloy (containing 30wt% zinc), 81.8wt% pure silver;

[0072] 2) Melting in a vacuum induction furnace: Put the above-mentioned weighed raw materials into a graphite crucible, mix well, fill it tightly and close the furnace cover, vacuumize to 4.9Pa, and then fill with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com