Composite galvanized army green steel pipe for refrigeration and manufacturing method of composite galvanized army green steel pipe

A manufacturing method and technology for steel pipes, applied in the field of steel pipe manufacturing, can solve the problems of heavy labor, heat-shrinkable tubes cannot protect steel pipes well, and monotonous colors, etc., and achieve high stability of finished products, good bright lines, and simple processes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

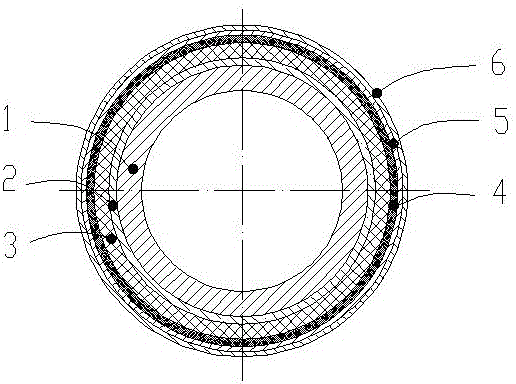

[0034] see figure 1 , the present embodiment is a composite galvanized military green steel pipe for refrigeration, including a steel pipe 1 located in the innermost layer, the steel pipe 1 is a pipe body made of low-carbon steel cold-rolled steel strip through high-frequency welding, and then reduced by drawing The outer surface of the steel pipe 1 is provided with a zinc-iron alloy layer 2, and the outer surface of the zinc-iron alloy layer 2 is attached with a pure zinc layer 3, and the outer surface of the pure zinc layer 3 is a military green passivation layer 4. A first sealing layer 5 and a second sealing layer 6 are respectively arranged outside the army green passivation layer 4 .

[0035] The manufacturing method of the composite galvanized military green steel pipe for refrigeration in this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com