Antibacterial glass composition and preparation method thereof

A glass composition and antibacterial technology, applied in the field of antibacterial glass composition and its preparation, can solve the problem of easy discoloration of antibacterial glass and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

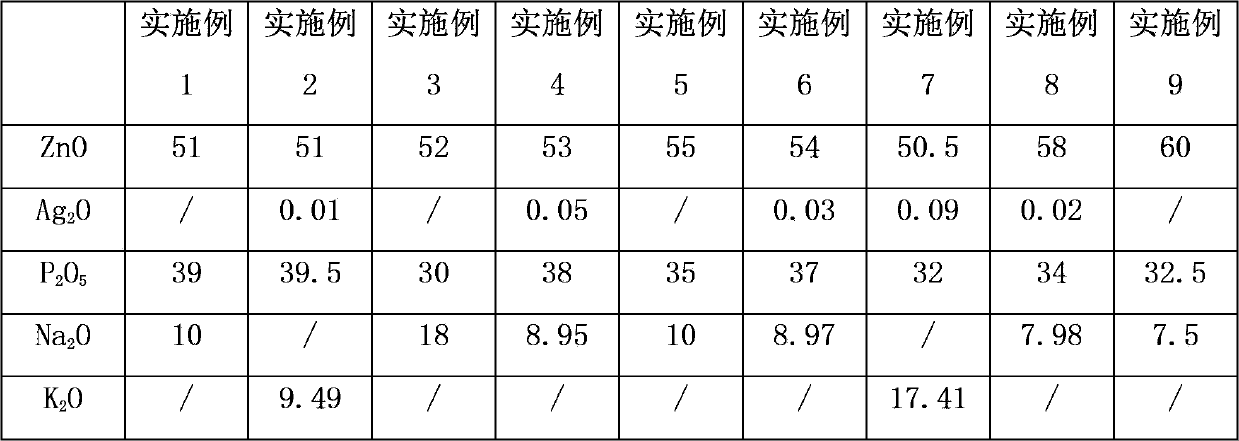

Embodiment 1

[0038] Weigh 100 g of ZnO, 96 g of P 2 o 5 , 20 g Na 2 O, mix evenly in a high-speed mixer, then place in a ceramic crucible, and keep the temperature in a high-temperature furnace at 600°C for 1 hour to form a melt-like liquid, then slowly pour the melt into cold water to form a preliminary crushed antibacterial glass , and then take out the antibacterial glass and dry it in an oven at 100°C for 30 minutes to make it fully dry. Then utilize jet mill to pulverize it into antibacterial glass powder with average particle size less than 20 microns. The composition of antibacterial glass powder was analyzed by X-ray energy spectrum analyzer (EDX), and its composition was calculated according to the oxide component: ZnO 51wt%, P 2 o 5 39wt%,Na 2 O10wt%.

Embodiment 2

[0040] Weigh 373 grams of Zn(NO 3 ) 2 ·6H 2 O, 0.03 g AgNO3, 65 g P 2 o 5 , 55 g KH 2 PO 4 , mixed evenly in a high-speed mixer, then placed in a ceramic crucible, kept in a high-temperature furnace at 700°C for 45 minutes to form a melt-like liquid, and then slowly poured the melt into cold water to form a preliminary crushed antibacterial glass, Then take out the antibacterial glass and dry it in an oven at 100°C for 30 minutes to make it fully dry. Then utilize jet mill to pulverize it into antibacterial glass powder with average particle size less than 20 microns. The composition of antibacterial glass powder is analyzed by energy spectrum analysis, and its composition is calculated according to the oxide component: ZnO 51wt%, Ag 2 O0.01wt%,P 2 o 5 39.5wt%, K 2 O 9.49wt%.

Embodiment 3

[0042] Weigh 120 g of ZnC 2 o 4 .2H 2 O, 50 g P 2 o 5 , 31 g Na 2 CO 3 , mixed evenly in a high-speed mixer, then placed in a ceramic crucible, kept in a high-temperature furnace at 800°C for 30 minutes to form a melt-like liquid, and then slowly poured the melt into cold water to form a preliminary crushed antibacterial glass, Then take out the antibacterial glass and dry it in an oven at 100°C for 30 minutes to make it fully dry. Then utilize jet mill to pulverize it into antibacterial glass powder with average particle size less than 10 microns. The composition of antibacterial glass powder is analyzed by energy spectrum analysis, and its composition is calculated according to the oxide component: ZnO 52wt%, P 2O 5 30wt%,Na 2 O18wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com