Novel explosion-proof film

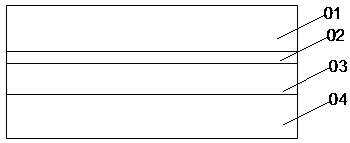

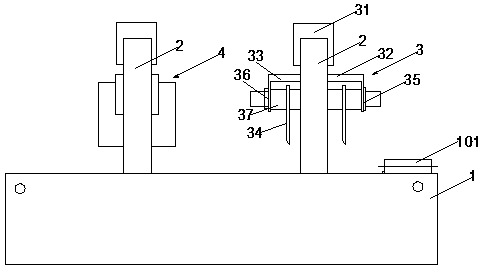

An explosion-proof film, a new technology, applied in the direction of adhesive type, pressure-sensitive film/sheet, film/sheet-shaped adhesive, etc., can solve the burr on the cutting edge, affect the quality of the final product, and the explosion-proof film is easy to shift and other problems, to achieve the effect of large peeling force, large market application promotion value, and high quality explosion-proof membrane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The following examples further illustrate the content of the present invention, but should not be construed as limiting the present invention. Without departing from the essence of the present invention, the modifications and substitutions made to the methods, steps or conditions of the present invention all belong to the scope of the present invention.

[0048] One: Preparation of OCA pressure sensitive adhesive

[0049] 10 parts of ethyl acrylate or butyl acrylate or isooctyl acrylate, 30 parts of methyl acrylate or vinyl acetate, 35 parts of methyl acrylate, 11.2 parts of methyl methacrylate, 3.8 parts of hydroxyethyl methacrylate or acrylic acid Hydroxyethyl ester, 52 parts of ethyl acetate solvent and 0.45 parts of initiator are mixed and stirred evenly, and added to the reaction vessel, stirred and heated to 80°C and maintained at this temperature, and 0.3 parts of initiator are added to the remaining 40 parts of ethyl acetate solvent Add the mixed solvent and in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| release force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com