Manufacturing process of hollow stabilizer rod of automobile

A manufacturing process and technology of stabilizer bars, applied in vehicle components, interconnection systems, suspensions, etc., can solve problems such as low strength, and achieve the effects of improving fatigue life, reducing the depth of decarburization layer, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

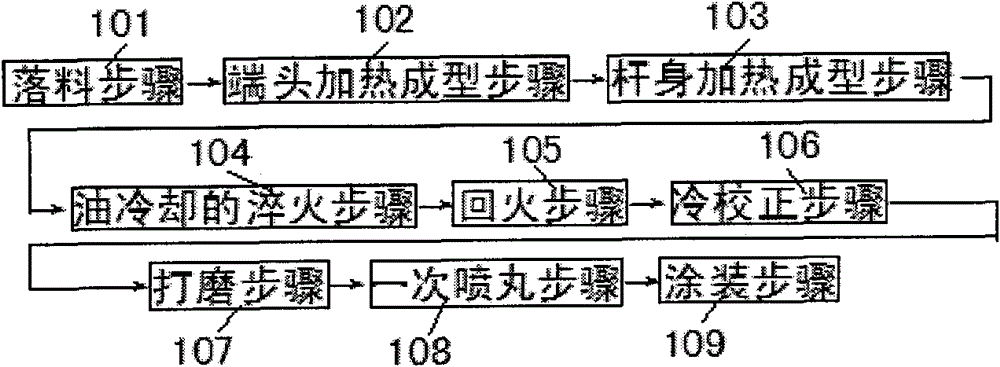

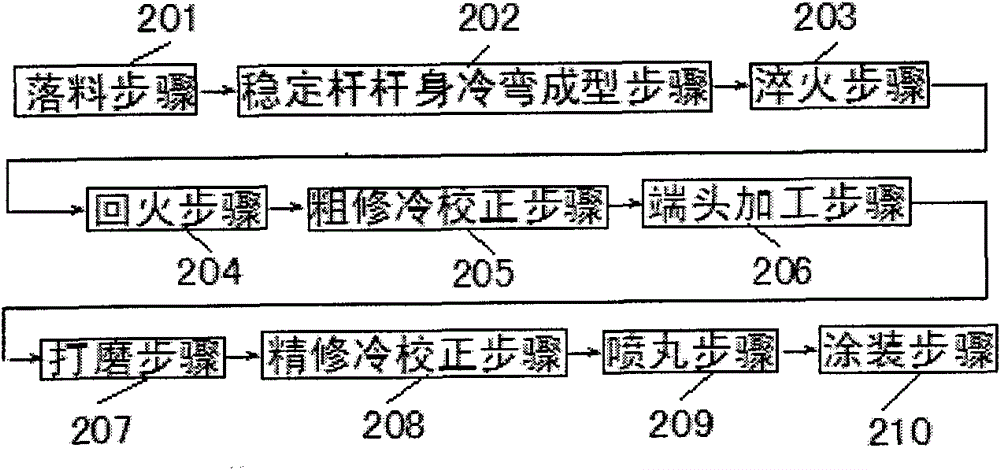

[0039] see figure 2 . The manufacturing process of the automobile hollow stabilizer bar of the present invention includes: blanking step 201 → raw material cold bending forming step 202 → quenching step 203 → tempering step 204 → rough repair and cold correction step 205 → end processing step 206 → grinding step 207 → finishing Cooling correction step 208 → shot peening step 209 → painting step 210 .

[0040] Below in conjunction with the specific embodiment of producing a kind of hollow stabilizer bar further illustrate characteristic performance of the present invention:

[0041] Blanking step 201: first select qualified raw materials, and cut the qualified hollow metal pipes into stabilizer bar single material according to the model specification of the stabilizer bar. When selecting raw materials, select low-carbon steel materials suitable for manufacturing hollow stabilizer bars. For example, the present embodiment takes the hollow stabilizer bars used on Chevrolet Cru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com