InP single crystal wafer twin polishing method and device

A double-sided polishing, double-sided polishing machine technology, applied in the field of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Preferred embodiments of the present invention will be specifically described below in conjunction with the accompanying drawings, wherein the accompanying drawings constitute a part of the application and are used together with the embodiments of the present invention to explain the principle of the present invention.

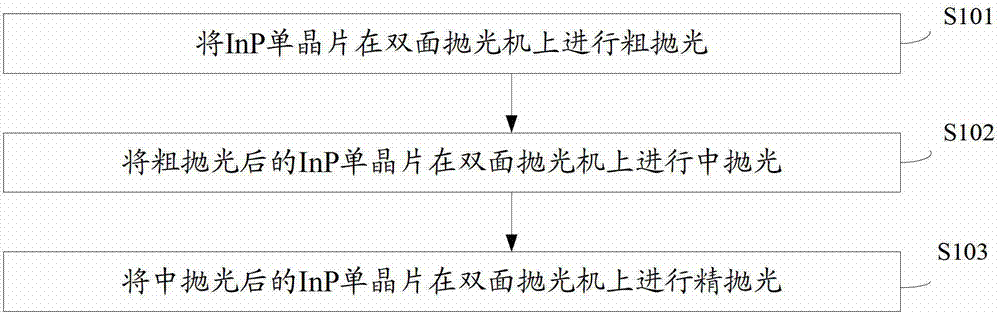

[0023] Embodiments of the present invention provide a double-sided polishing method for an InP single wafer, see figure 1 , the method includes:

[0024] S101, roughly polishing the InP single wafer on a double-sided polishing machine;

[0025] The rough polishing liquid in the embodiment of the present invention comprises alkaline colloidal silicon dioxide suspension, deionized water and sodium dichloroisocyanurate, and alkaline colloidal silicon dioxide suspension: deionized water: sodium dichloroisocyanurate The volume ratio is 1:10:(1.0~1.8), the pH value of the rough polishing liquid is 10-11, and the pressure of the rough polishing is (150~170) g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com