Cavity machining track planning method based on numerical control operation system

A technology of trajectory planning and operating system, applied in general control system, control/adjustment system, program control, etc., can solve the problems of inconsistent surface quality and roughness of groove cavity machining, and ensure the machining surface quality, high efficiency and flexibility. processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

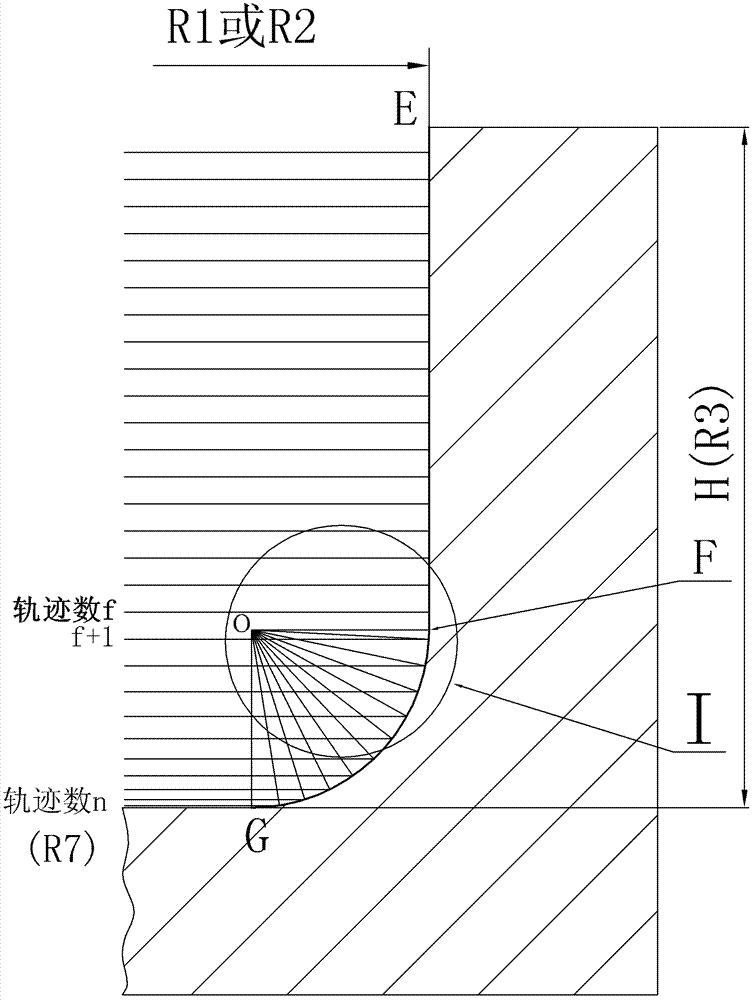

[0031] Specific implementation mode one: as Figure 1-10 As shown, the groove machining trajectory planning method based on the numerical control operating system described in this embodiment is implemented according to the following steps:

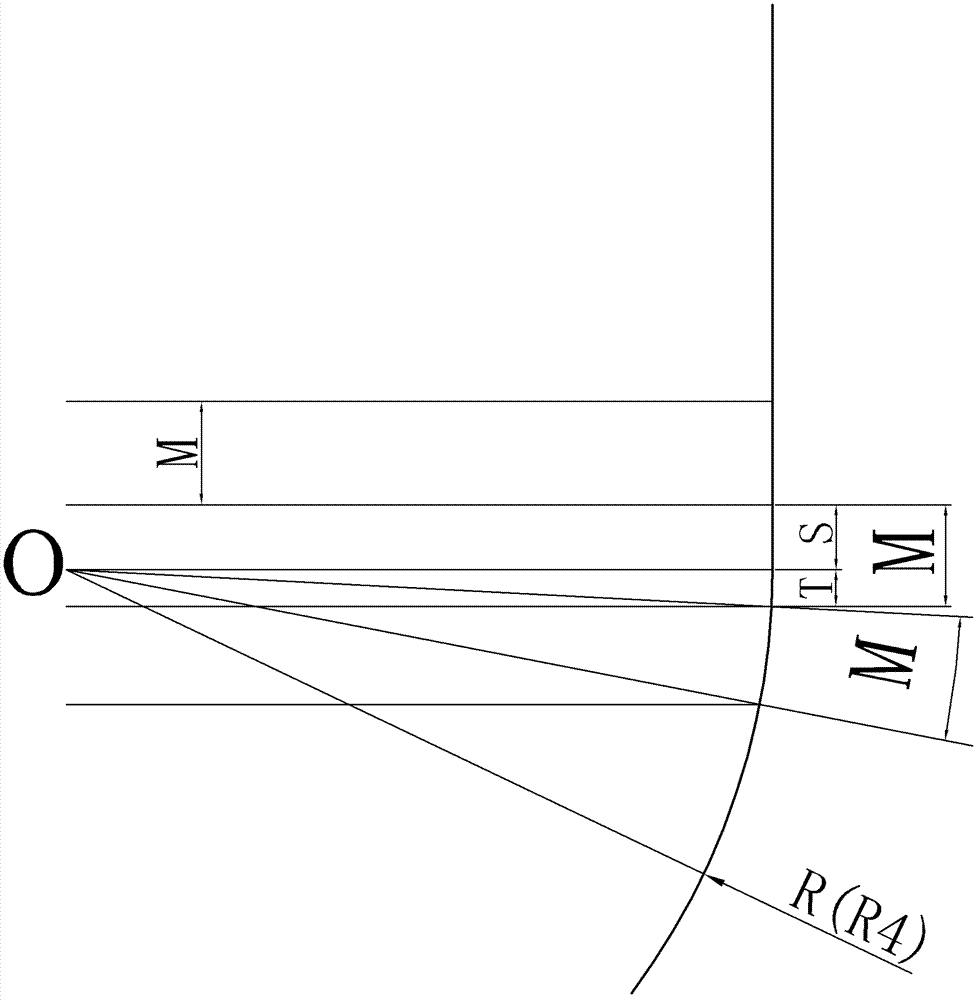

[0032] Step A, based on the longitudinal section depth direction boundary trajectory of the groove on the drawing is the combination line segment of the longitudinal section diagram composed of straight lines and arcs, the number of times n of the machining trajectory in the depth direction of the tool (parameter R in the program) 7 ) as a set condition variable to plan a set of evenly arranged point sets projected on the combined line segment of the longitudinal profile, and the distance between every two adjacent points is the step of the distance between two adjacent trajectories projected on the combined line segment of the longitudinal profile The long value M, and then control the uniform arrangement of the projected spacing of the ...

specific Embodiment approach 2

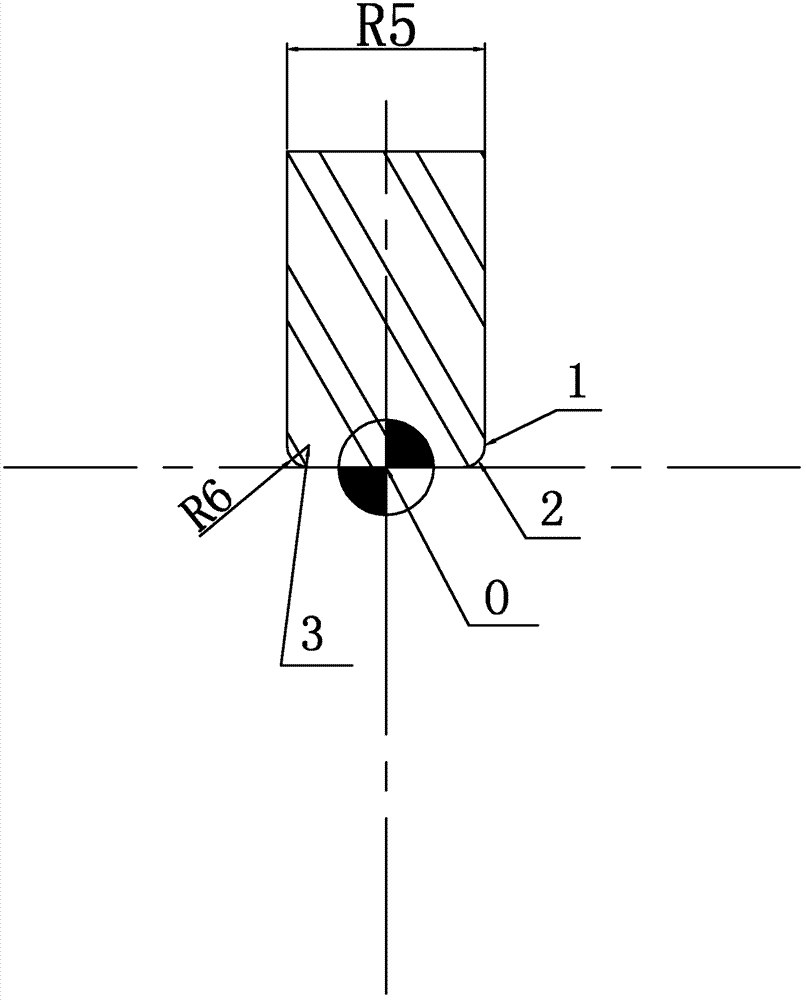

[0058] Specific implementation mode two: see image 3 The groove machining trajectory planning method based on the numerical control operating system described in this embodiment also includes step B: calculating the groove side fixed cutting edge (1 ), the compensation value of the tool setting point (O) of the groove fillet surface dynamic cutting edge (2) and the tool, describes the track of the tool setting point; The fillet radius R. Other steps are the same as in the first embodiment.

[0059] Tool selection: Because the side wall of the groove is straight and the rounded bottom is a rounded surface, it is more suitable for us to choose a rounded end mill, which can not only improve the processing efficiency of the side wall, but also meet the surface quality of the rounded surface , so that we can describe the trajectory of the tool cutting point 1 and 2 relative to the workpiece zero point G54 according to the incremental method (such as the schematic diagram of the ...

specific Embodiment approach 3

[0060] Specific implementation mode three: as Figure 1-5 and Figure 6 As shown, this embodiment is a specific process of programming using the method of the present invention:

[0061] Step 1. The trajectory of the edge-rounded groove is evenly arranged and planned:

[0062] Based on the known dimensions of the groove profile on the drawing (see Figure 4 ) Considering that the longitudinal section boundary trajectory of the groove is a combination curve of a straight line and a circular arc process, through a series of calculation methods, according to the number of machining trajectories n of the tool in the depth direction (the parameter R in the program 7 ) setting to plan a group of uniformly arranged point sets projected on the combined line of the longitudinal section, and then control the uniform arrangement of the projected spacing of the tool layer cutting trajectory on the inner surface of the groove (see Figure 6 ).

[0063] Step 2. Calculate the compensatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com