Rolling tool,apparatus,method,and gear for producing convex teeth

A technology of rolling and tools, which is applied to gears, household appliances, hoisting devices, etc., can solve problems such as small tolerances and difficulty in obtaining, and achieve the effect of simplifying tool manufacturing and prolonging rolling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] First of all, it should be ascertained that in the differently described embodiments, the same parts are designated by the same reference numerals or the same component designations, wherein the disclosure contained in the entire description can reasonably be transferred to the same reference numerals or components. On the same part with the same component name. Positional indications selected in the description, such as top, bottom, side, etc., also refer to the currently described or shown figure and can be transferred to the new position as appropriate in the event of a position change.

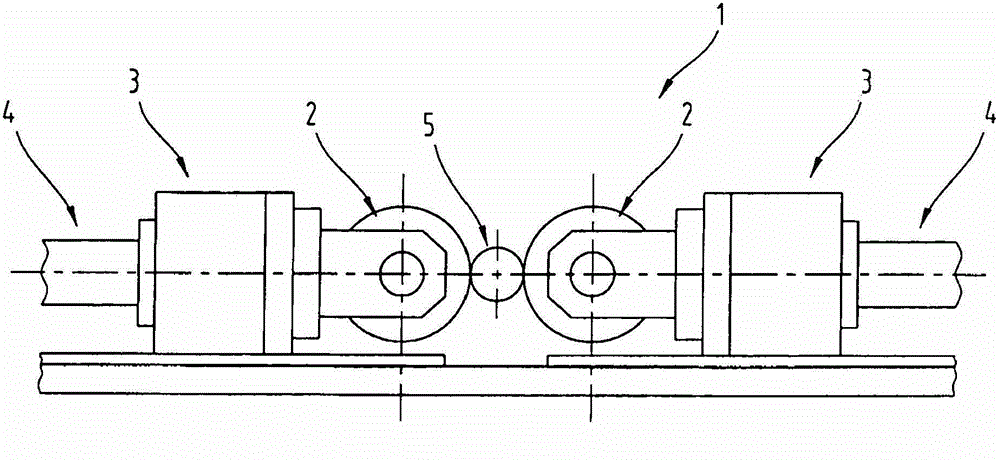

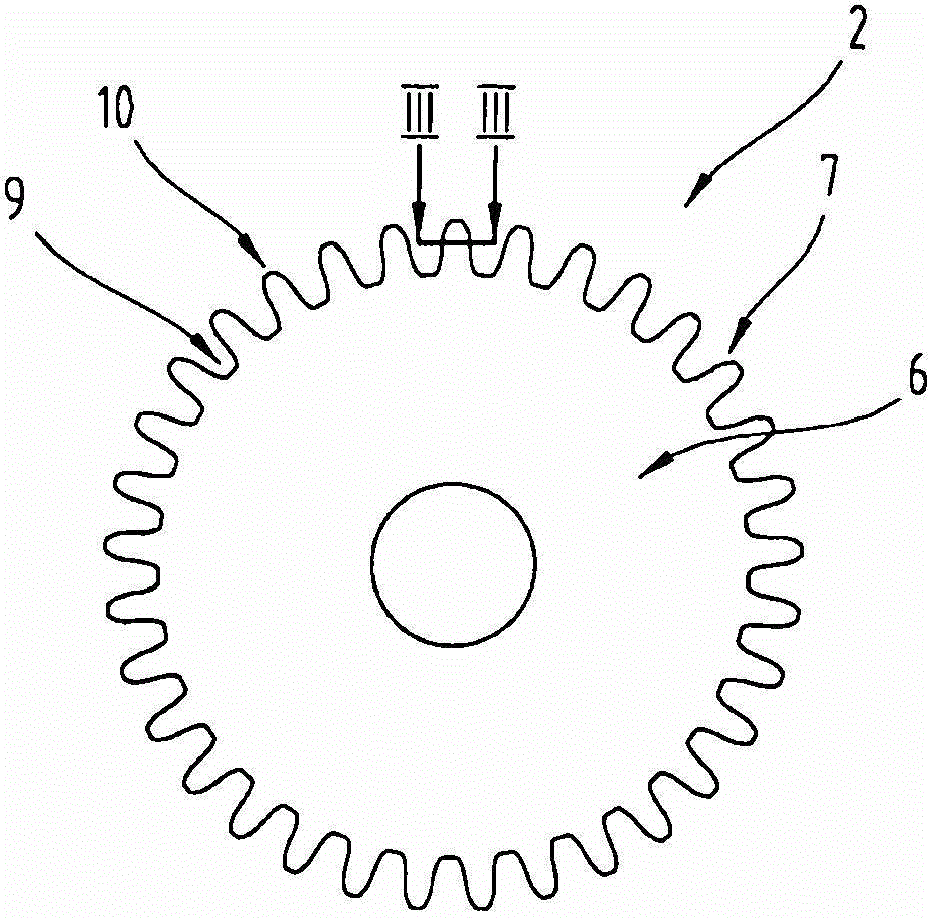

[0036] figure 1 A device 1 for rolling gear teeth is shown, as is known from the prior art. The device 1 comprises two gear-shaped rolling tools 2 which are each held rotatably in a holding device 3 , in particular a rolling slide. The holding devices 3 are here arranged on their respective carriage spindles 4 .

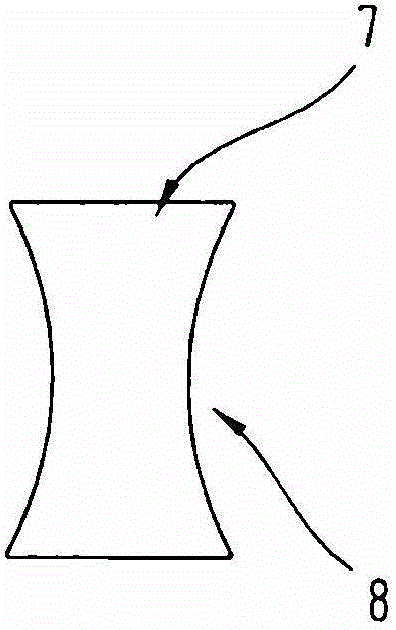

[0037] The rolling tool 2 , ie its toothing, is in meshing engagem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com