Color printing ink applied to tempered glass

A technology of tempered glass and ink, applied in ink, application, household appliances and other directions, can solve the problems of poor printing effect and low ink adhesion, and achieve the effect of good printing effect, fast drying speed and smooth ink surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

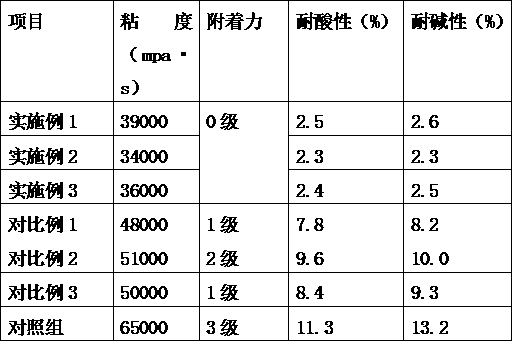

Examples

Embodiment 1

[0017] A color printing ink applied to tempered glass, made of the following components in parts by weight: 46 parts of ink base liquid, 30 parts of pigment, 1.2 parts of dispersant, 0.6 part of leveling agent, and 0.3 part of thixotropic agent;

[0018] The ink base liquid is made of the following components in terms of mass percentage: polyethylene resin accounts for 25%, hydroxyl acrylic resin accounts for 18%, polyester resin accounts for 15%, rosin modified phenolic resin accounts for 6%, polymethacrylic butyl Esters account for 3%, and the rest are blending solvents;

[0019] The preparation and use method of the color printing ink comprises the following steps:

[0020] (1) Mix the ink base liquid, pigment, dispersant, leveling agent, and thixotropic agent, pre-disperse into a slurry at a speed of 500 rpm, and then disperse and stir at a speed of 2000 rpm for 30 minutes. Transfer to a three-roll mill and grind for 2 times, and grind until the particle size is between 1...

Embodiment 2

[0026] A color printing ink applied to tempered glass, made of the following components in parts by weight: 48 parts of ink base liquid, 33 parts of pigment, 1.25 parts of dispersant, 0.7 part of leveling agent, and 0.4 part of thixotropic agent;

[0027] The ink base liquid is made of the following components in terms of mass percentage: polyethylene resin accounts for 28%, hydroxyl acrylic resin accounts for 19%, polyester resin accounts for 16%, rosin modified phenolic resin accounts for 8%, polymethacrylic butyl Esters account for 4%, and the rest are blending solvents;

[0028] The preparation and use method of the color printing ink comprises the following steps:

[0029] (1) Mix the ink base liquid, pigment, dispersant, leveling agent, and thixotropic agent, pre-disperse into a slurry at a speed of 550 rpm, and then disperse and stir at a speed of 2200 rpm for 35 minutes. Transfer to a three-roll mill and grind for 2 times, and grind until the particle size is between ...

Embodiment 3

[0035] A color printing ink applied to tempered glass, which is made of the following components in parts by weight: 50 parts of ink base liquid, 35 parts of pigment, 1.3 parts of dispersant, 0.8 part of leveling agent, and 0.5 part of thixotropic agent;

[0036] The ink base liquid is made of the following components in terms of mass percentage: polyethylene resin accounts for 30%, hydroxyl acrylic resin accounts for 20%, polyester resin accounts for 18%, rosin modified phenolic resin accounts for 10%, polymethacrylate butyl Esters account for 5%, and the rest are blending solvents;

[0037] The preparation and use method of the color printing ink comprises the following steps:

[0038] (1) Mix the ink base liquid, pigment, dispersant, leveling agent, and thixotropic agent, pre-disperse into a slurry at a speed of 600 rpm, and then disperse and stir at a speed of 2400 rpm for 40 minutes, Transfer to a three-roller grinder and grind 3 times until the particle size is between ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com